Lifting device for pipeline installation construction

A technology of pipeline installation and lifting platform, applied in the direction of lifting device, etc., can solve problems such as difficult handling, and achieve the effect of convenient transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

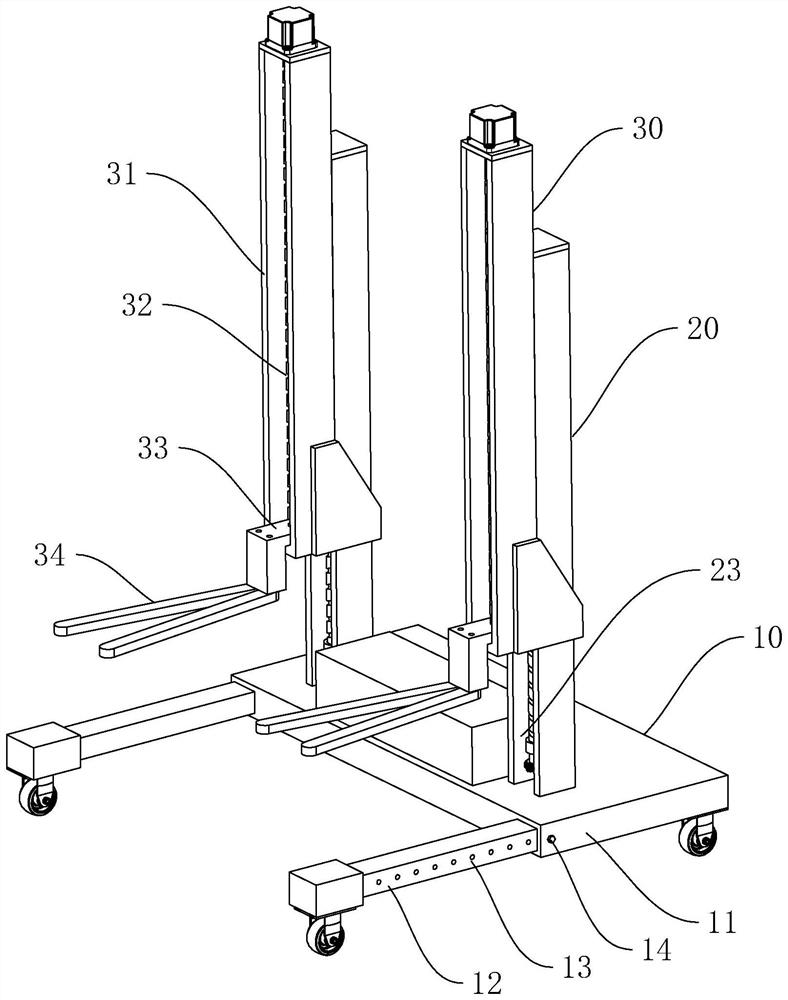

[0037] Embodiment 1, the embodiment of the present application discloses a lifting device for pipeline installation and construction, refer to figure 1 , including a mobile platform 10, on which a lifting assembly for lifting the ventilation system assembly is arranged.

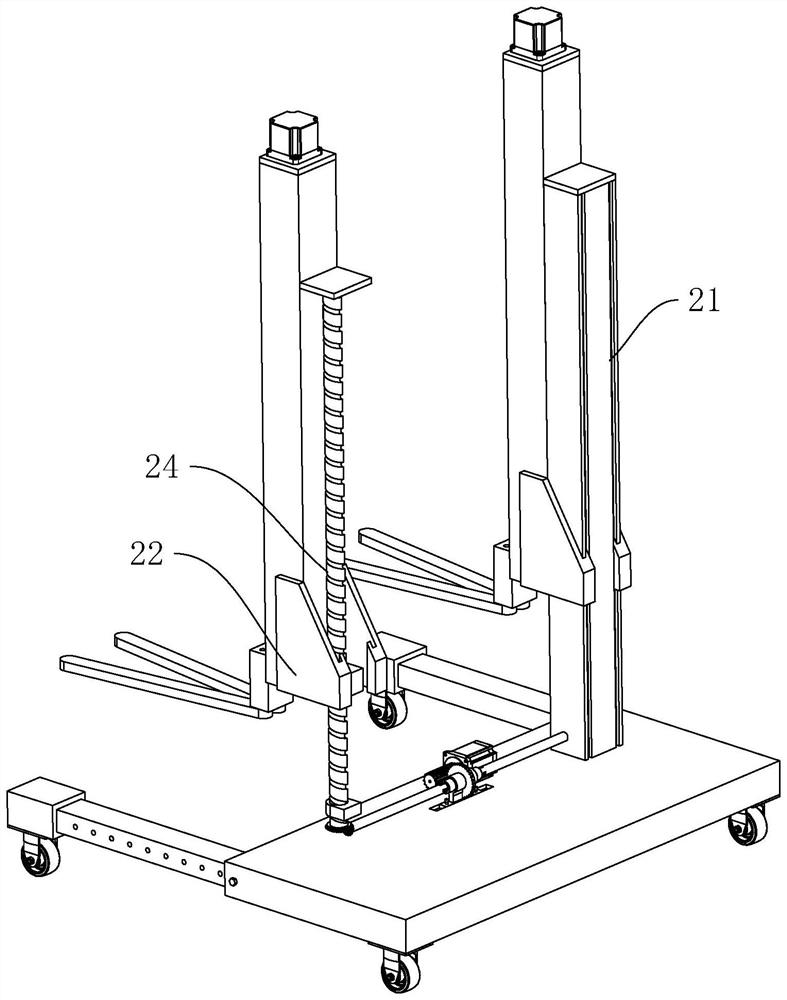

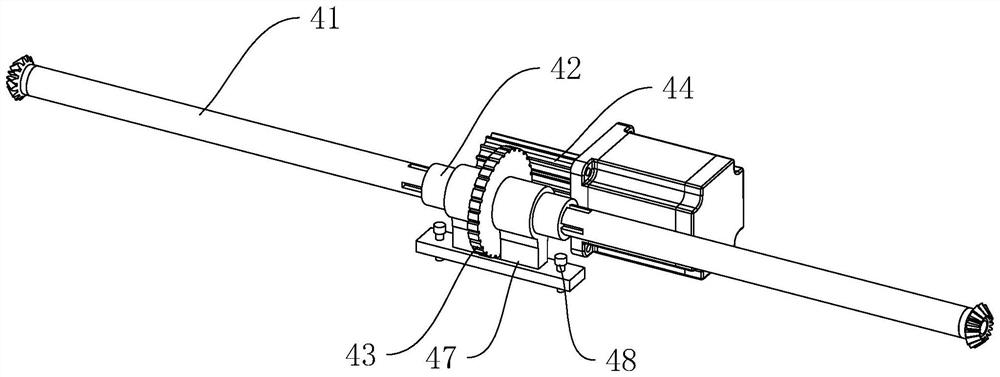

[0038]There are two sets of lift assemblies, each set of lift assemblies includes a first lift unit 20 and a second lift unit 30, the first lift unit 20 includes a first column 21 fixed on the mobile platform 10, and the first column 21 is provided with The first lifting platform 22 and the first driving mechanism that drives the first lifting platform 22 to move relative to the first column 21, the second lifting unit 30 includes a second column 31 fixed on the first lifting platform 22, and the second column 31 is provided There is a second lifting platform and a second driving mechanism that drives the second lifting platform to slide relative to the second column 31. When in use, the second lifting platfo...

Embodiment 2

[0049] Example 2, refer to Image 6 The difference between this embodiment and Embodiment 1 is that the base 11 is provided with a rotating shaft, the support arm 12 is hinged with the rotating shaft, the rotating shaft is arranged vertically, and in the folded state, the support arm 12 is located below the second lifting platform. When the support arm 12 is in the retracted state, it can support the fork 34, and when stored for a long time, the shearing force of the fork 34 on the second driving mechanism can be reduced by its own weight.

Embodiment 3

[0050] Example 3, refer to Figure 7 and Figure 8 The difference between this embodiment and Embodiment 2 is that the rotating shaft is arranged horizontally, and in the folded state, the support arm 12 rotates to a state parallel to the first column 21 . The base 11 is provided with a first running wheel 15 and a transition wheel 17, and the support arm 12 is provided with a second running wheel 16. In the folded state, the base 11 can rotate with the transition wheel 17 as a fulcrum to configure the lifting device in a standing posture and a lying state. In the posture state, the fork 34 needs to be removed before switching to the lying posture state; in the standing posture state, the first running wheel 15 and the transition wheel 17 are carried, and in the lying posture state, the second running wheel 16 and the transition wheel are carried.

[0051] When the support arm 12 is in the folded state, the whole lifting device can be pushed on the ground in a lying position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com