Rapid growth method of large-sized graphene glass

A growth method and graphene technology, applied in graphene, nano-carbon, metal material coating processes, etc., can solve the problems of uneven layer thickness, limited size, weak cracking ability, etc., and achieve concentration distribution and airflow distribution. Uniformity, ensuring uniformity, and enhancing the effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

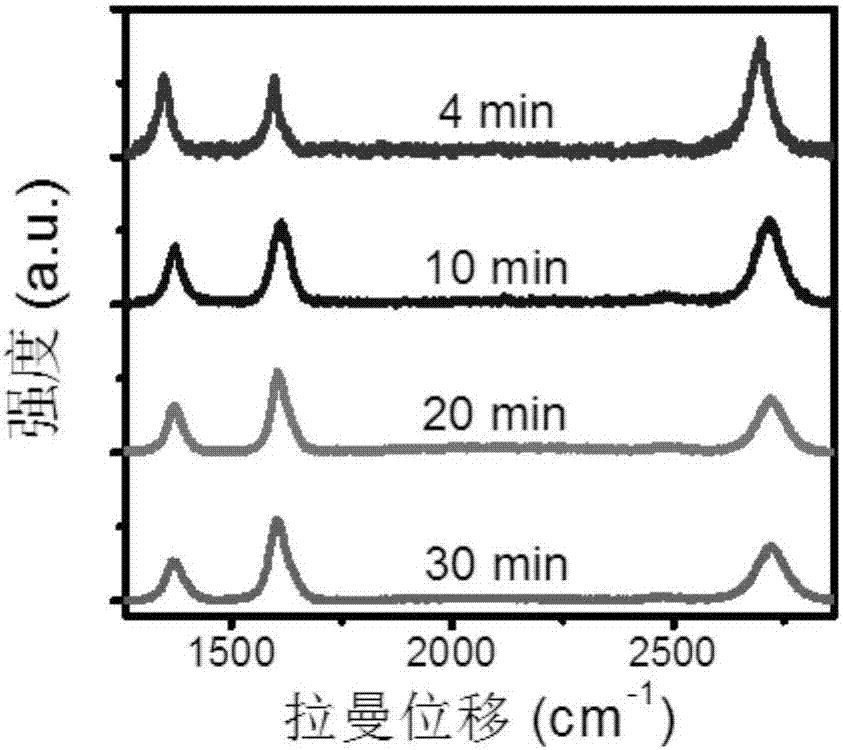

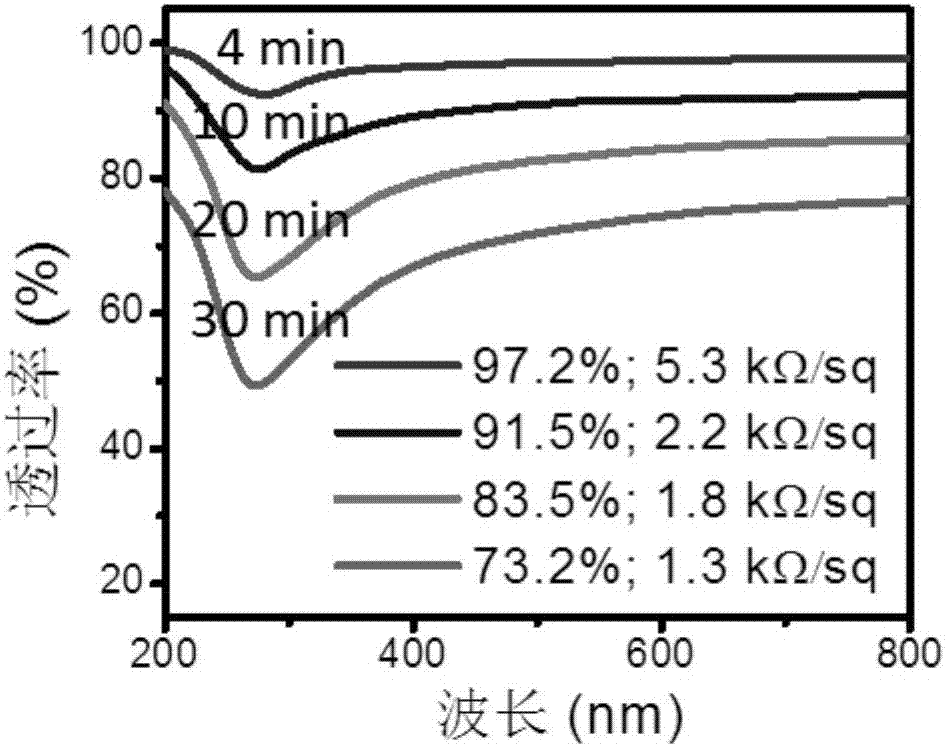

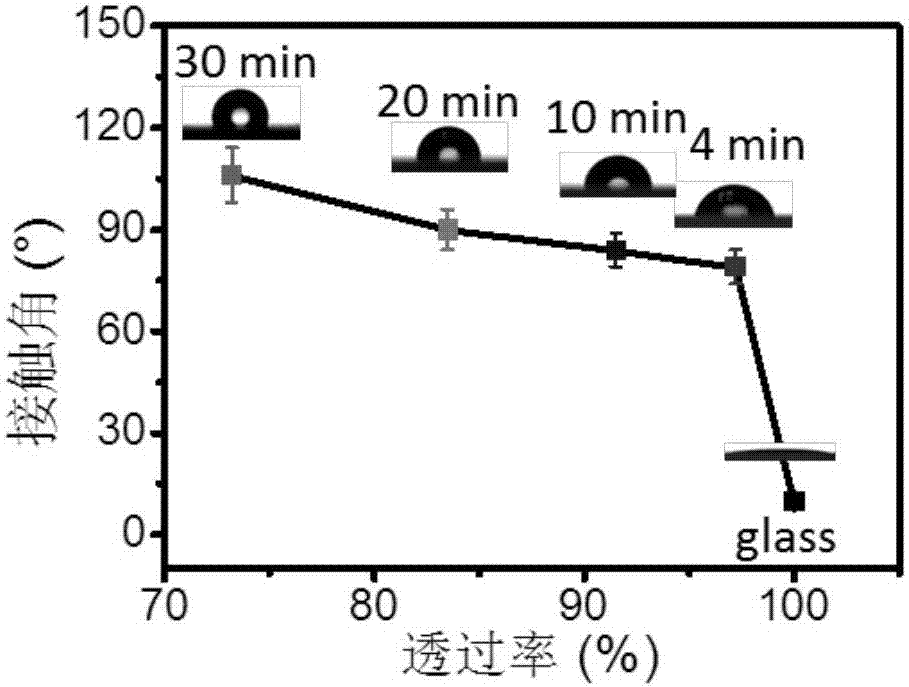

Embodiment 1

[0033] Ultrasonic cleaning is used to place 60cm*6cm (diagonal length about 25 inches) of quartz glass in acetone, ethanol, and deionized water for 10 minutes, blow dry with nitrogen, clean it, and put it into a high-temperature tube at 1100°C. In the type furnace, use an oil-free scroll vacuum pump to pump the pressure in the reaction chamber to below 10Pa, evacuate, and pass Ar / H 2 1000 / 1000sccm, open the ethanol gas valve after the airflow is stable, ethanol vapor enters the reaction chamber and quickly cracks into activated carbon species, a large number of activated carbon species are adsorbed to the surface of quartz glass, migrate and collide on the surface, thereby realizing the nucleation and growth of graphene . The ethanol flow rate was set to 500 sccm, the partial pressure was 250 Pa, and the graphene growth process was set to 4 minutes. After the growth, the ethanol valve was quickly closed, and the Ar / H 2 Set to 300 / 300sccm, start the cooling process of the sam...

Embodiment 2

[0036] Ultrasonic cleaning method is used to place 50cm*6cm quartz glass in acetone, ethanol, and deionized water for 10 minutes, blow dry with nitrogen, clean it, and put it into a 3-inch diameter high-temperature tube furnace at 1100 °C. Use an oil-free scroll vacuum pump to evacuate the pressure in the reaction chamber to below 10Pa, and inject Ar / H 2 1000 / 1000sccm, open the ethanol gas valve after the airflow is stable, ethanol vapor enters the reaction chamber and quickly cracks into activated carbon species, a large number of activated carbon species are adsorbed to the surface of quartz glass, migrate and collide on the surface, thereby realizing the nucleation and growth of graphene . The ethanol flow rate was set to 500 sccm, the partial pressure was 250 Pa, the graphene growth process was set to 10 minutes, and the ethanol valve was quickly closed after the growth was over, and the Ar / H 2 Set to 300 / 300sccm to start the cooling process. After the temperature in th...

Embodiment 3

[0039] Use ultrasonic cleaning method to place 40cm*6cm quartz glass in acetone, ethanol, and deionized water for 10 minutes, blow dry with nitrogen, clean it, put it in a high-temperature tube furnace at 1100°C, and use an oil-free vortex The vacuum pump pumps the pressure in the reaction chamber to below 10Pa, and the Ar / H 2 1000 / 1000sccm, open the ethanol gas valve after the airflow is stable, ethanol vapor enters the reaction chamber and quickly cracks into activated carbon species, a large number of activated carbon species are adsorbed to the surface of quartz glass, migrate and collide on the surface, thereby realizing the nucleation and growth of graphene . The ethanol flow rate was set to 500 sccm, the partial pressure was 250 Pa, the graphene growth process was set to 20 minutes, and the ethanol valve was quickly closed after the growth was over, and the Ar / H 2 Set to 300 / 300sccm to start the cooling process. After the temperature in the reaction chamber drops to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com