Pre-magnetizing system

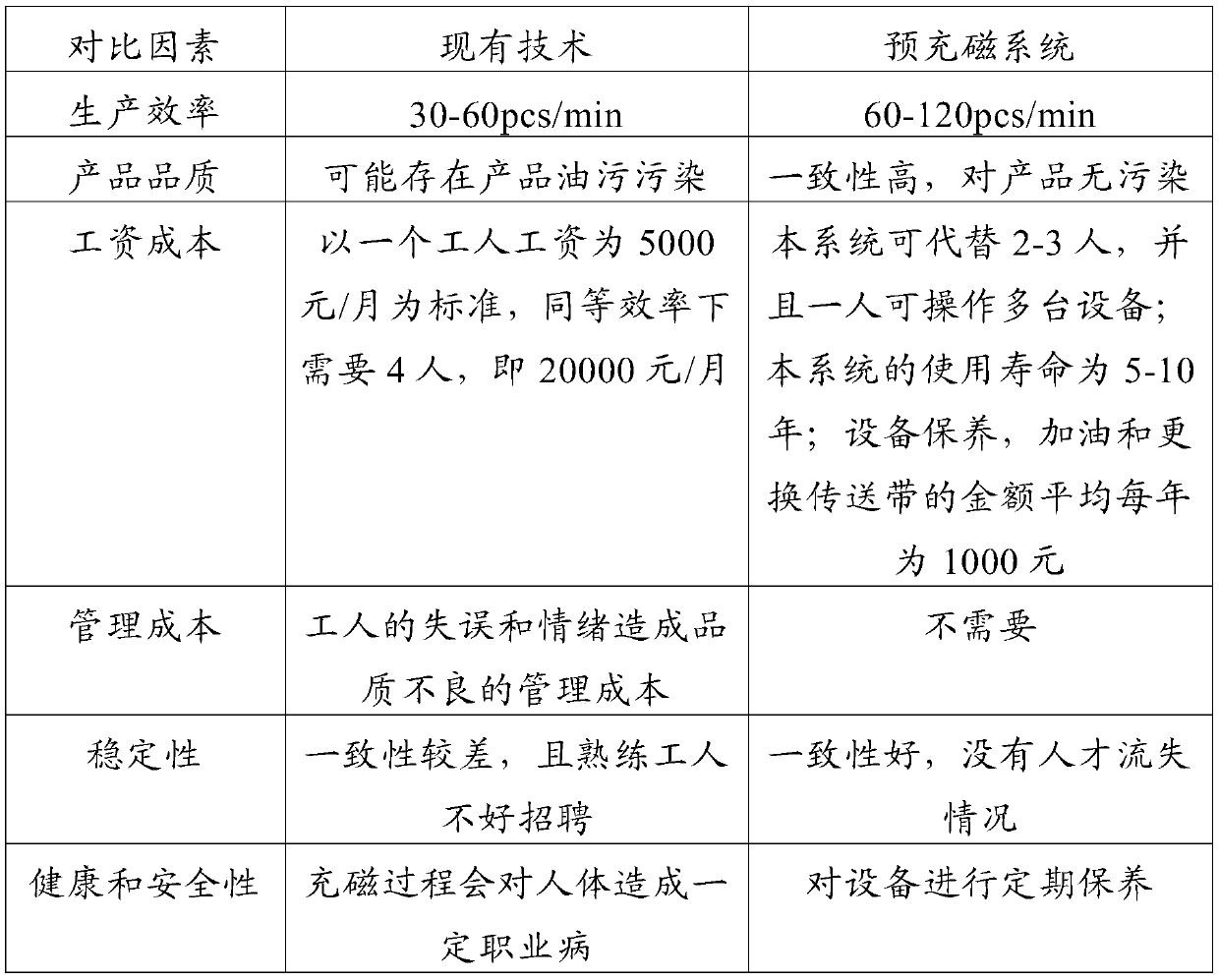

A pre-magnetization and magnetization device technology, applied in the field of pre-magnetization systems, can solve problems affecting product quality, magnetization collisions, and low production efficiency, so as to improve product quality and pass rate, reduce power loss, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

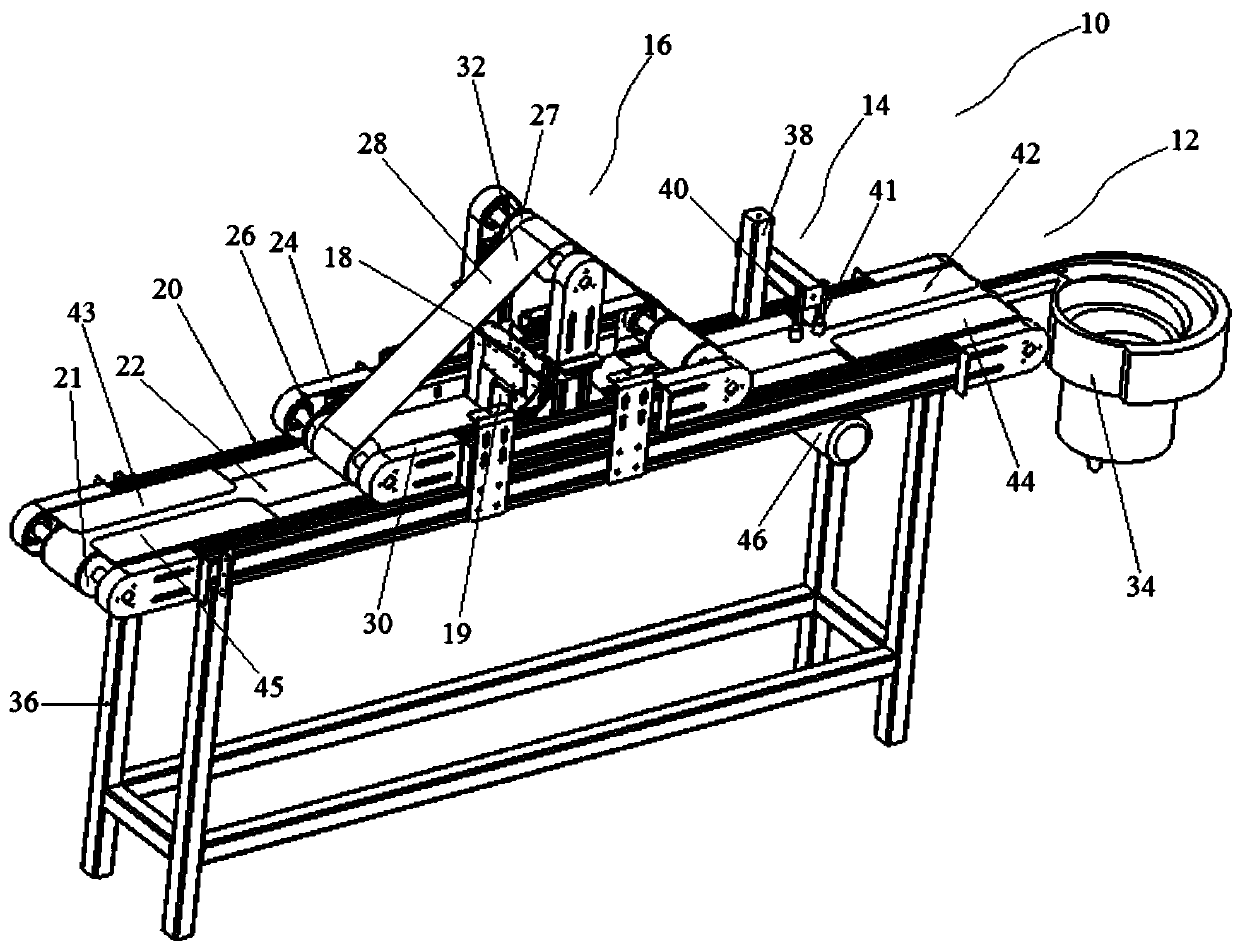

[0019] The following will combine Figure 1 to Figure 2 , to further elaborate the present invention.

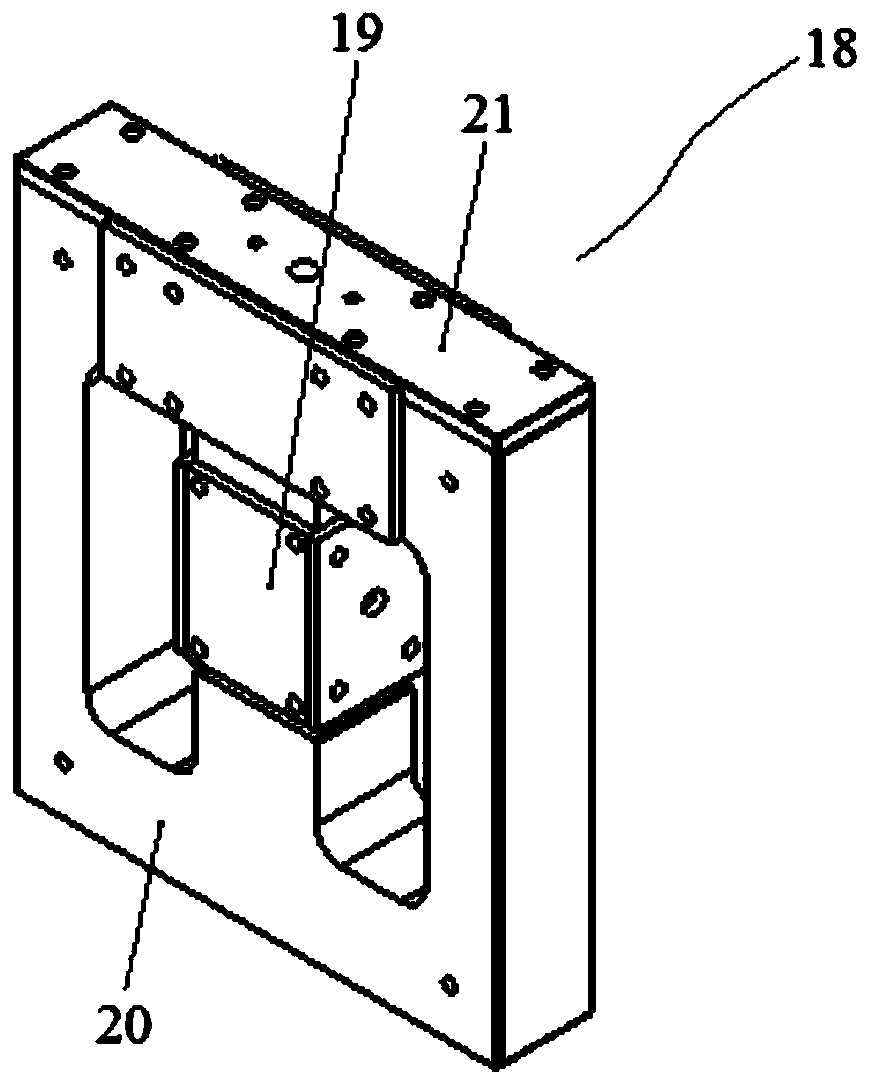

[0020] figure 1 A pre-magnetization system 10 according to an embodiment of the present invention is shown, including: a conveying device 12; a coding device 14, which is arranged above the conveying device 12; a compacting device 16, which is arranged on Above the conveying device 12 , and relative to the conveying direction of the conveying device 12 , the compacting device 16 is located downstream of the coding device 14 ; the magnetizing device 18 includes a permanent magnet 19 disposed on the compacting device 16 . In other words, after the product is put into the conveying device 12 , it first passes through the coding device 14 for coding, and then passes through the compacting device 16 and uses the magnetizing device 18 for pre-magnetization. In one embodiment, the permanent magnet 19 is a fully magnetized NdFeB square with a specification of 51*47*32T, T is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com