Low-temperature multi-effect evaporative crystallization process and crystallization equipment

A multi-effect evaporation and crystallization equipment technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of unstable environmental pressure, poor reaction evaporation effect, etc., to avoid damage problems, strengthen strength, The effect of improving the crystallization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiments of the present invention, and not all embodiments.

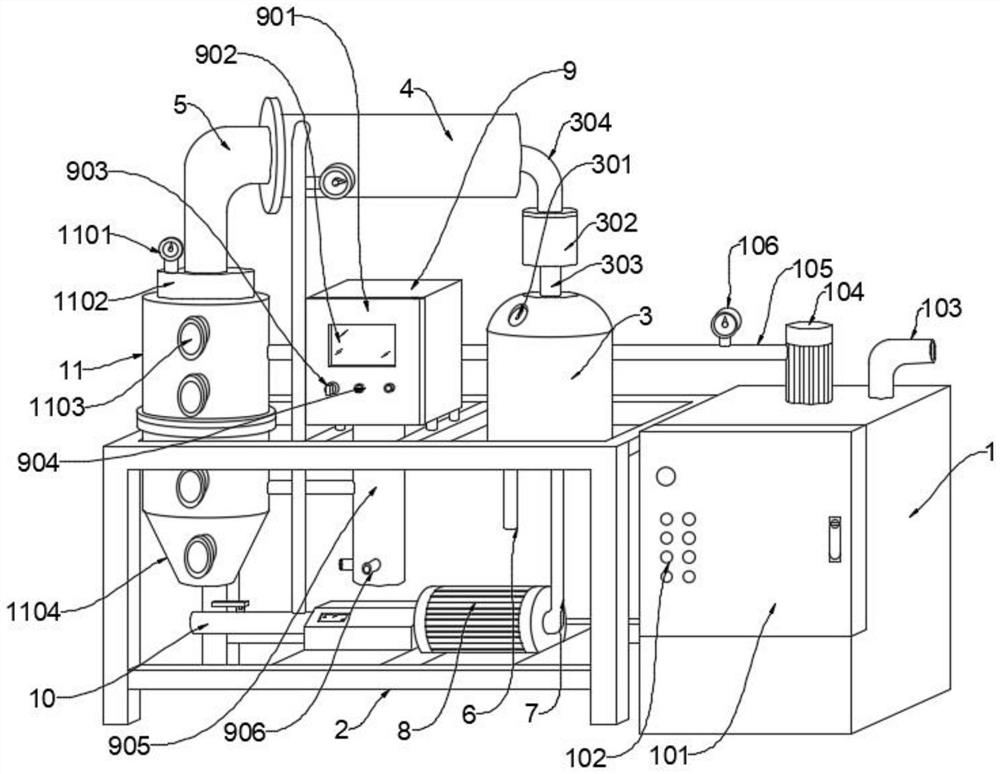

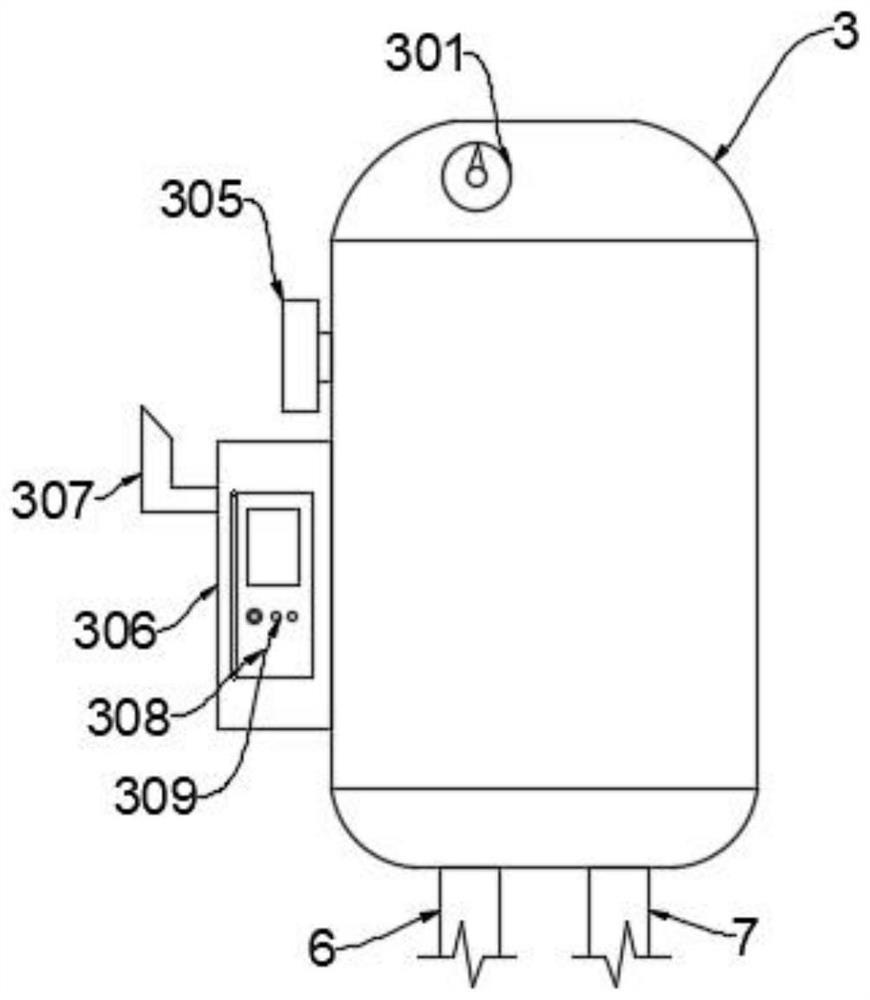

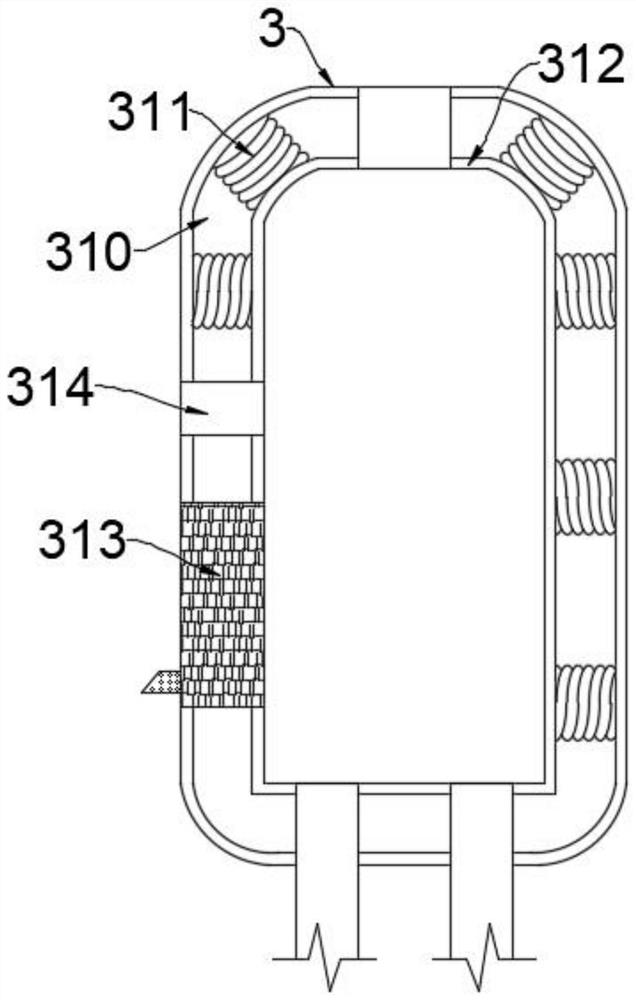

[0031] See Figure 1-5, one embodiment of the present invention provided: a low-temperature multi-effect evaporation crystallization apparatus, comprising a feeding device 1, mounting bracket body 2, pressure reduction equipment 3, filter pipe equipment 4, a second pump 8, additive equipment 9 and reaction equipment 11, the upper end surface of the feeding equipment 1 is provided with a pumping mechanism 104, the pumping mechanism 104 is fixedly connected to the reaction equipment 11 through the first connection of the transmission pipeline 105, the first connection to the upper end surface of the transmission pipeline 105 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com