Ball mill filling rate measuring device

A measuring device and filling rate technology, applied in cleaning methods and utensils, chemical instruments and methods, level indicators of level members, etc., can solve the problem of extrusion damage of zero-degree positioning ruler and sheath, reduction of positioning effect of zero-point positioning ruler, The gap between the zero point positioning ruler and the sheath, etc., achieves the effect of increasing practicability, increasing cleaning effect, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following technical solutions of the present invention are further described in conjunction with the accompanying drawings and by specific embodiments.

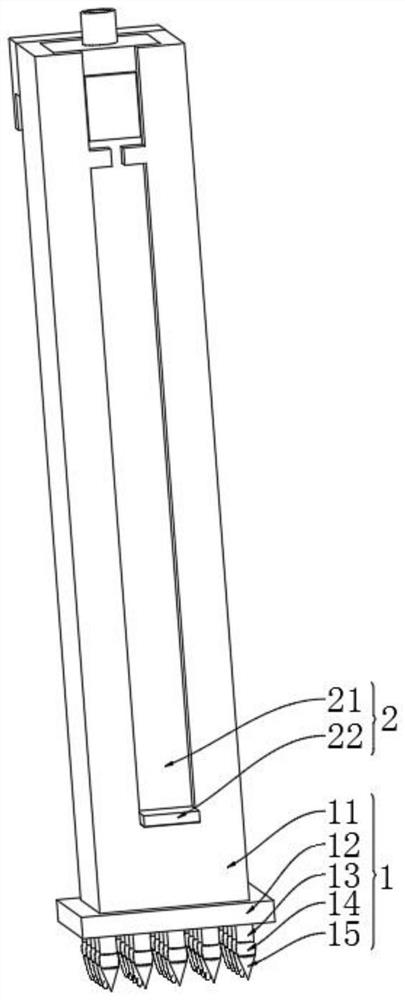

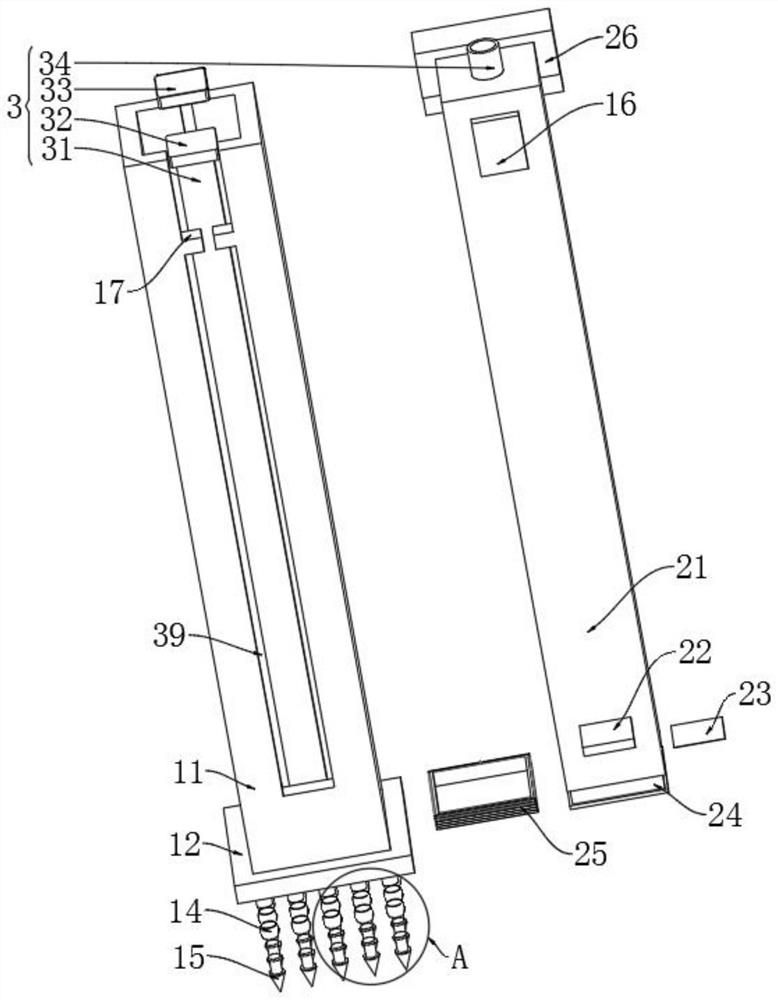

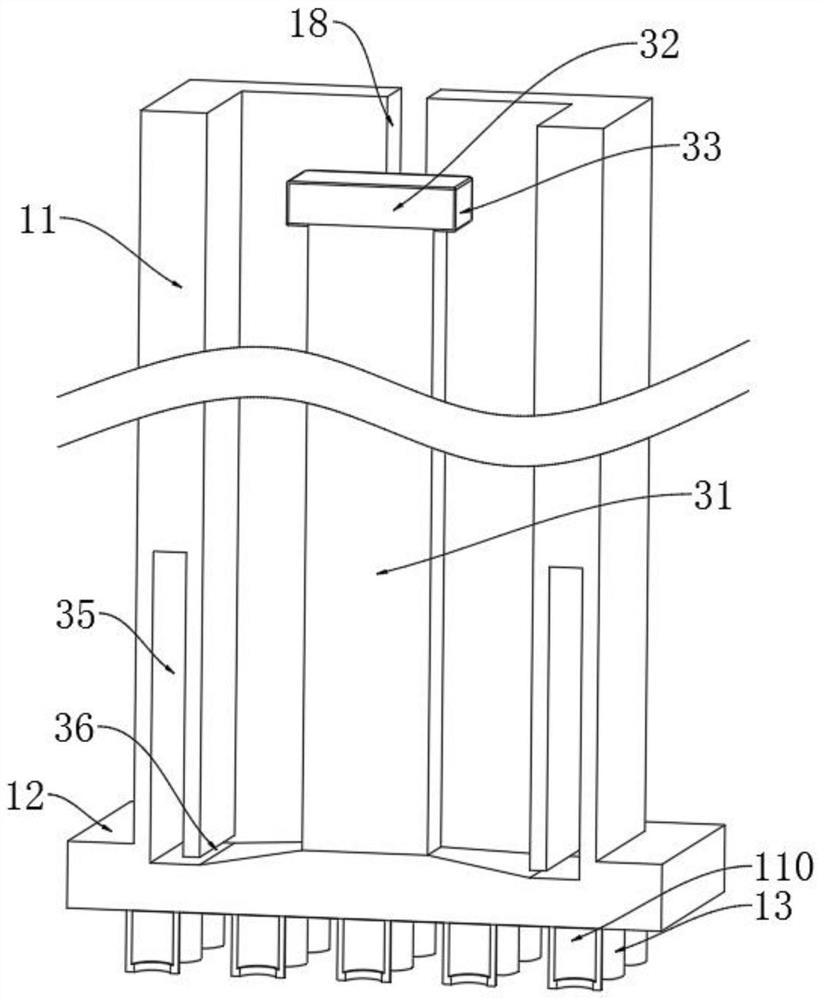

[0031] as Figure 1-5 As shown, the embodiment provides a ball mill filling rate measurement device, comprising a positioning detection structure 1, positioning detection structure 1 comprising a sliding sheath 11, the internal setting of the sliding sheath 11 is provided with a protective structure 2, the protective structure 2 includes a measuring slide ruler 21, the measuring slide ruler 21 sliding card is connected to the inside of the sliding sheath 11, the internal setting of the positioning detection structure 1 and the cleaning structure 3, the cleaning structure 3 includes the inner sliding card rod 31, the inner slip card rod 31 is fixed and connected to the middle of the sliding sheath 11, Measuring slide ruler 21 in the middle of the open inner sliding cavity 38, the inner slip card rod 31 sliding card is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com