Self-adaptive front-end air inlet system for oil smoke monitoring

An air intake system, self-adaptive technology, applied in measurement devices, air quality improvement, instruments, etc., can solve problems such as deviation of test results, false reports of restaurants, restaurant fines, etc., to avoid serious interference and reduce losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a further description of the present invention in conjunction with the accompanying drawings.

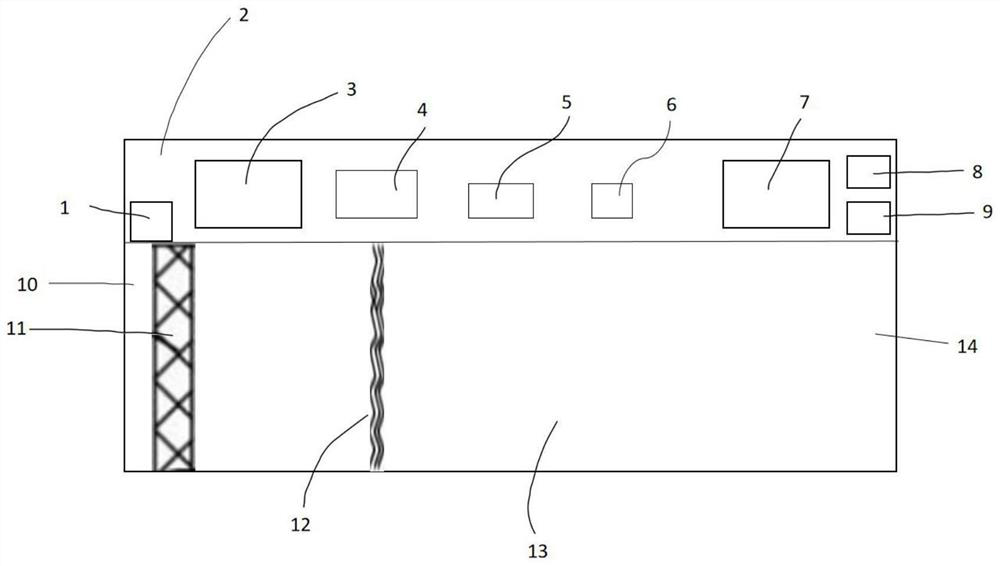

[0028] Please refer to figure 1 , as a concrete example, Figure 1 It is a schematic structural diagram of an adaptive front-end air intake system for oil fume monitoring according to an embodiment of the present invention.

[0029] An adaptive front-end air intake system for oil fume monitoring, comprising an air chamber 13, a first temperature and humidity sensor 3, a second temperature and humidity sensor 7, a drive circuit 6, a single-chip microcomputer 5, an air pump, a gas drying device 12, and a gas heating and cooling device 4, Metal filter 11 and siren 8.

[0030] The air chamber 13 is arranged in the middle position of the whole body 2 of the oil fume monitoring adaptive front-end air intake system. The air chamber 13 is a center-symmetric structure. One end of the air chamber 13 is provided with an air inlet 10, and the opposite end is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com