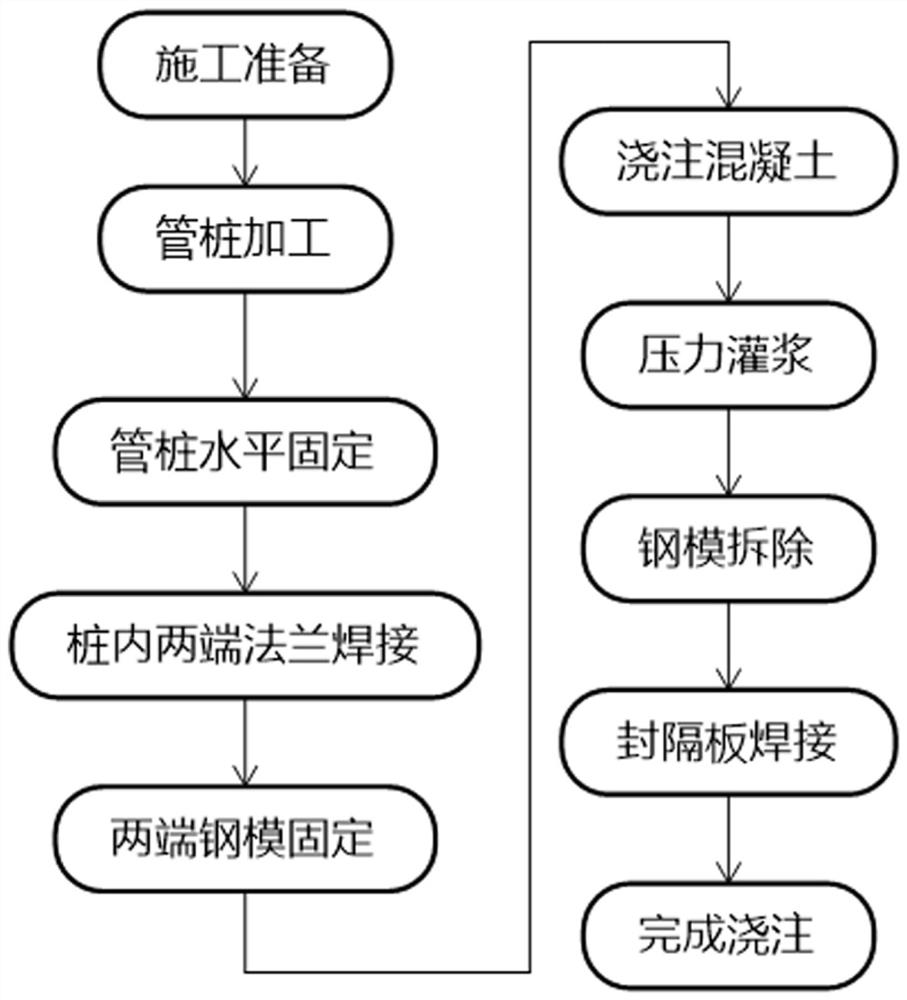

Construction method for prefabricating offshore wind power implanted socketed pile foundation bottom sealing concrete on land

A back-sealing concrete, offshore wind power technology, applied in infrastructure engineering, wind power generation, installation/support of wind turbine configuration, etc., to reduce offshore construction, facilitate onshore construction, and improve construction work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

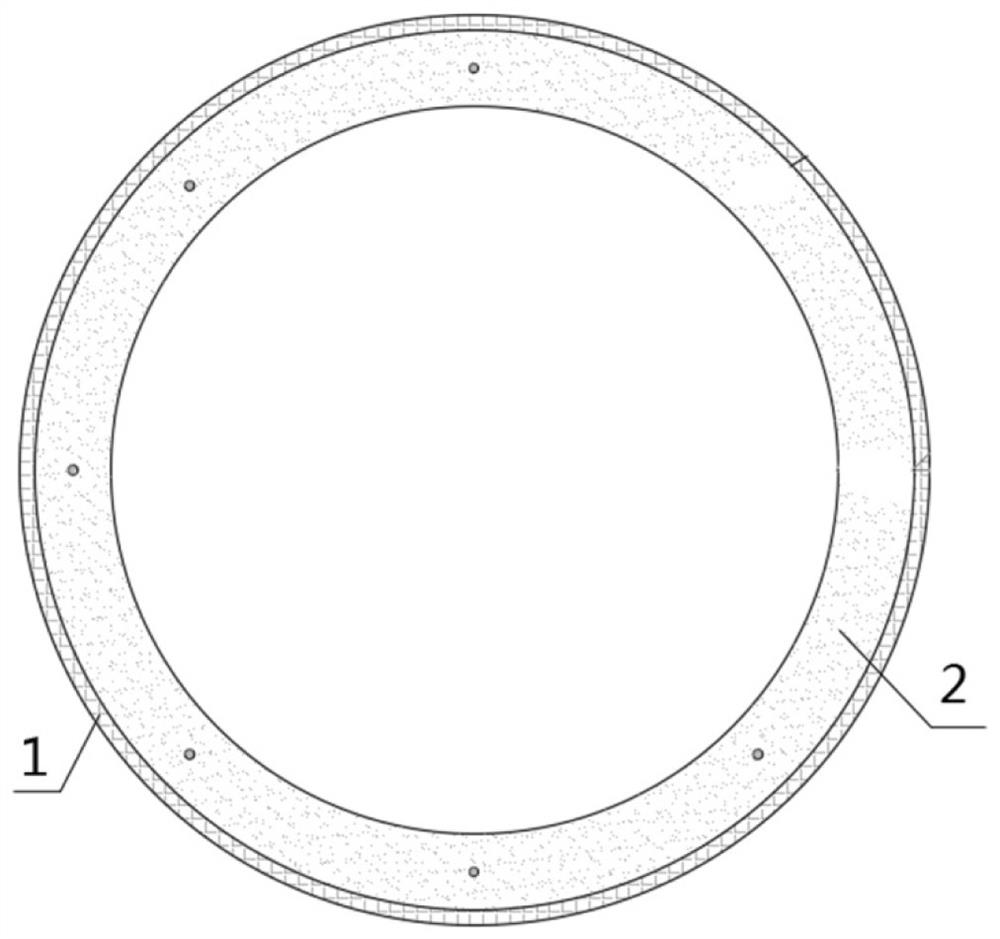

[0029] In a preferred solution, in the steps S4 and S5, a plurality of attached vibrators are arranged at equal intervals on the outer surface of the steel pipe pile 1 to continuously vibrate during the grouting process.

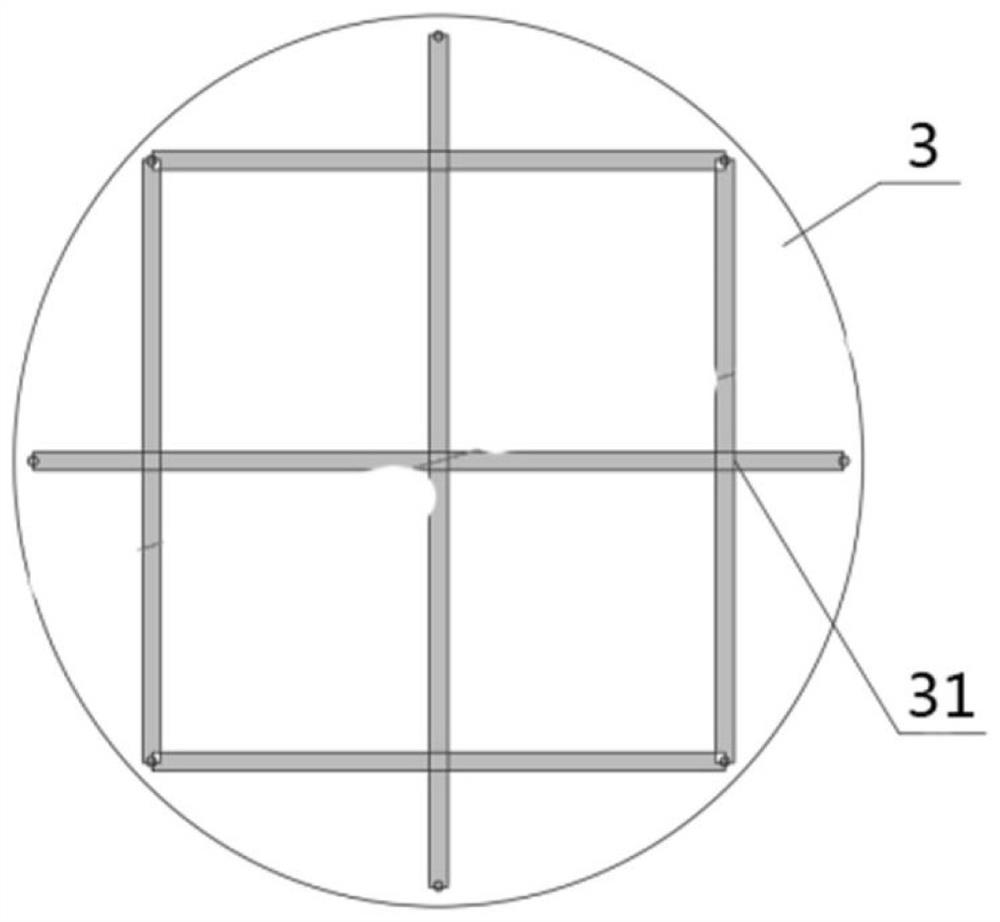

[0030] In a preferred solution, in the step S5, after the grouting is completed, the steel mold 3 at the end B of the inner end of the steel pipe pile is not removed. In this step, the steel mold 3 is used to protect the grouting pipeline 71 from being damaged.

[0031] The above-mentioned embodiments are only preferred technical solutions of the present invention, and should not be regarded as limitations on the present invention. The embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other if there is no conflict. The scope of protection of the present invention shall be the technical solution described in the claims, including equivalent replacements for the technical features in the technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com