Method for repairing goose neck part under hot blast bustle pipe of blast furnace air supply system

A technology of hot air surrounding pipe and air supply system, applied in blast furnace parts, blast furnace, blast furnace details, etc., can solve the problems of redness, weak anti-burning ability, affecting production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

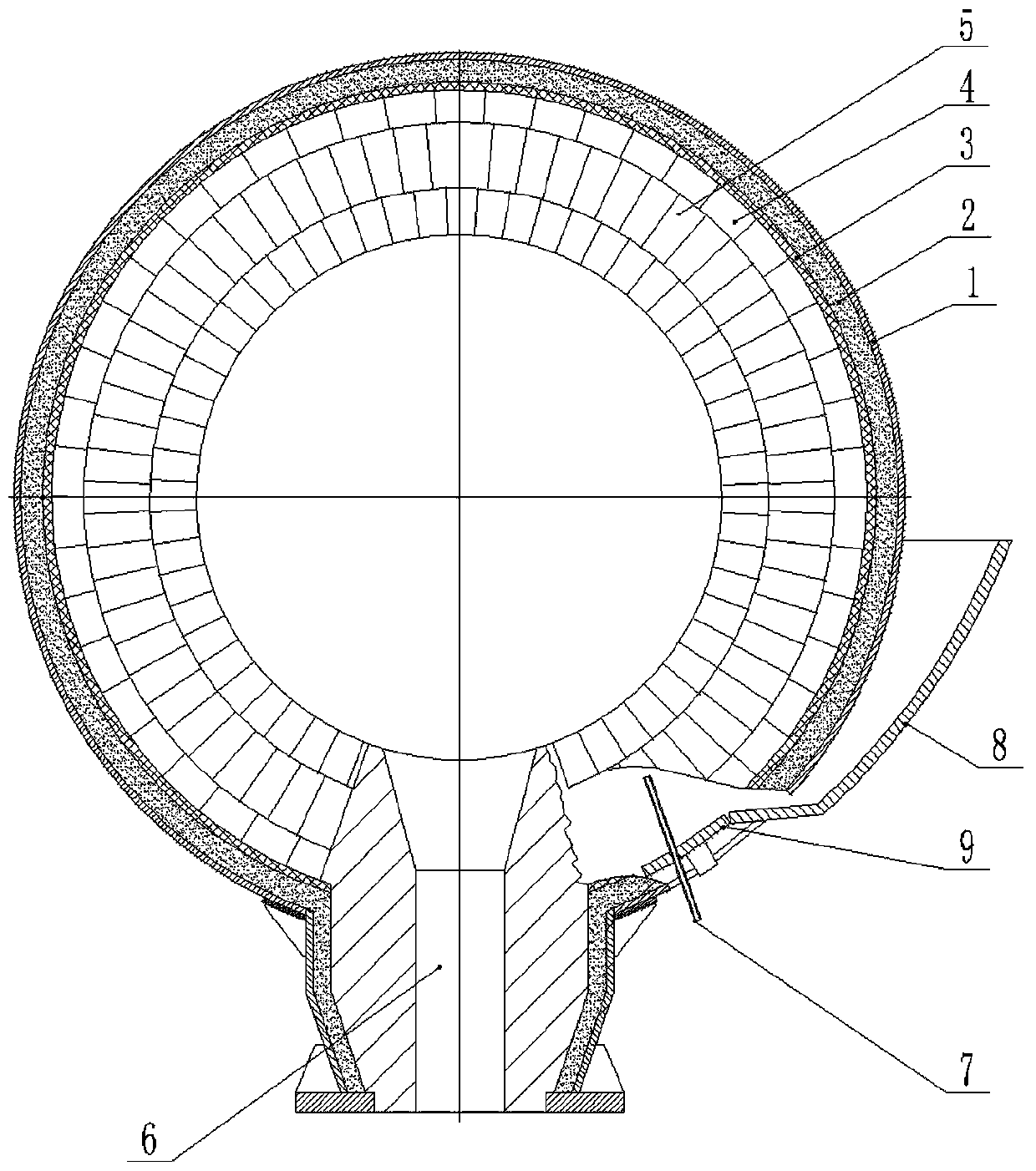

[0018] Such as figure 1 As shown, the structure of the hot air enclosure from the outside to the inside is: steel shell 1, spray paint 2, fiber felt 3, clay insulation brick 4, high-alumina insulation brick 5, refractory bricks for the working layer, and the middle of the gooseneck. High-alumina heat-insulating bricks with low refractoriness and weak resistance to burning loss, clay heat-insulating bricks, etc. will burn out after high-temperature gas with a temperature greater than 1100 ° C accumulates in this part for a long time, and form a In large-area hollow areas, after 6 to 12 months of operation, there will be large-scale redness or even burn-through accidents at the joints between the lower part of the casing and the gooseneck, which will cause the blast furnace to shut down and affect production.

[0019] A kind of repairing of the goose neck under the hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com