Double-column wave-dissipating body one-time prefabricating template

A one-time, template technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of time-consuming and material-consuming, affecting construction efficiency, and apparent defects of wave-absorbing bodies, so as to improve work efficiency, improve apparent quality, and save money. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

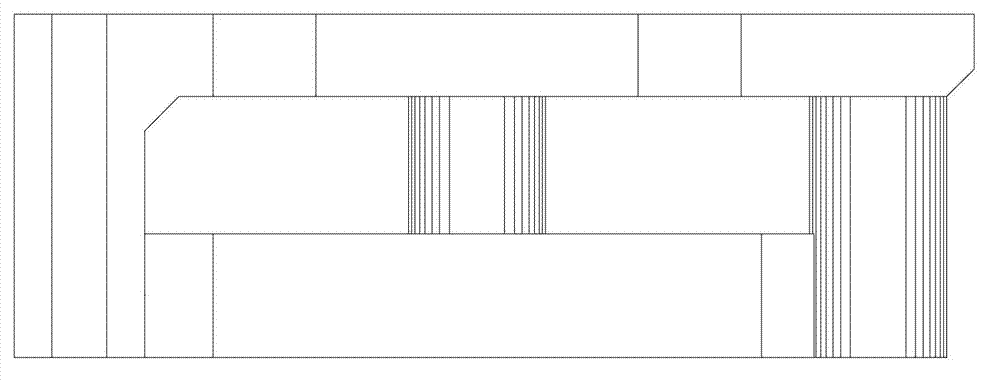

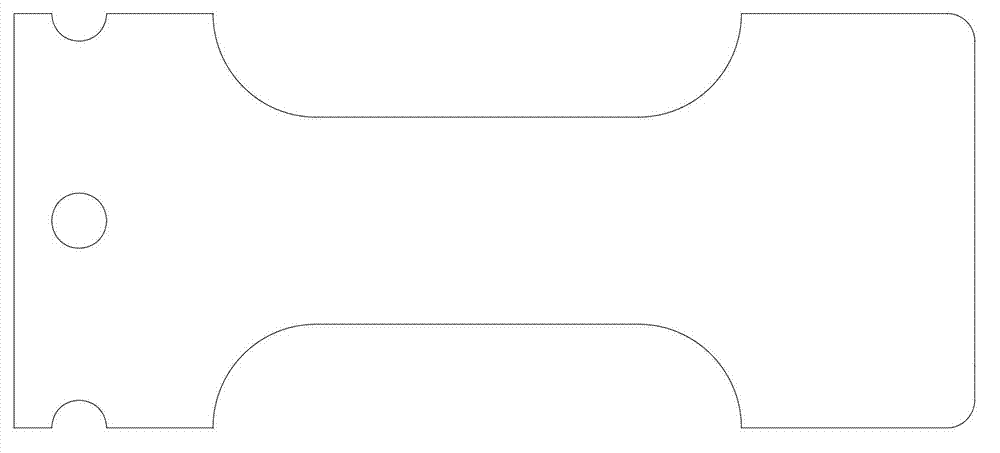

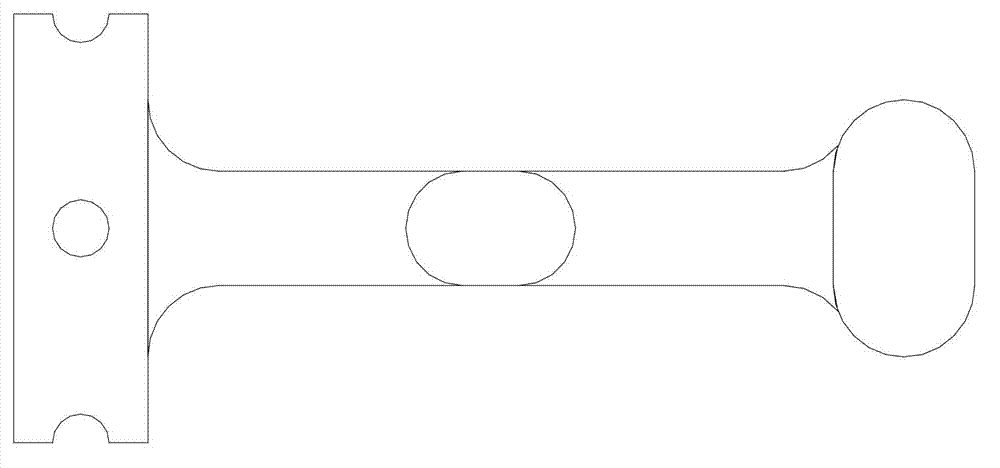

[0027] Example 1, such as Figure 1-6 As shown, this embodiment discloses a prefabricated Figure 1-3 A one-time prefabricated formwork for the double-column wave-dissipating body, the formwork includes a top form 1 and a bottom form 2, the top form 1 and the bottom form 2 are connected by a column form 3, and a wire is installed between the top form 1 and the bottom form 2 Supported by bars 4, the corners of the top mold and the bottom mold are hingedly connected, and the outer sides of the top mold 1 and the bottom mold 2 are covered with purlins 5, and the purlins 5 are fixed and clamped with braces 6. The truss structure is installed between the top form and the purlins and between the bottom form and the purlins. T-shaped rubber strips are embedded at the bottom corner of the formwork and the seam of the formwork, and attached vibrators are distributed around the formwork. The formwork, truss structure and purlins are all made of channel steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com