A method for repairing the gooseneck under the hot air surrounding pipe of a blast furnace air supply system

A technology of hot air surrounding pipes and air supply systems, which is applied to blast furnace parts, blast furnaces, and details of blast furnaces, and can solve problems such as burn-through, redness, and production impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

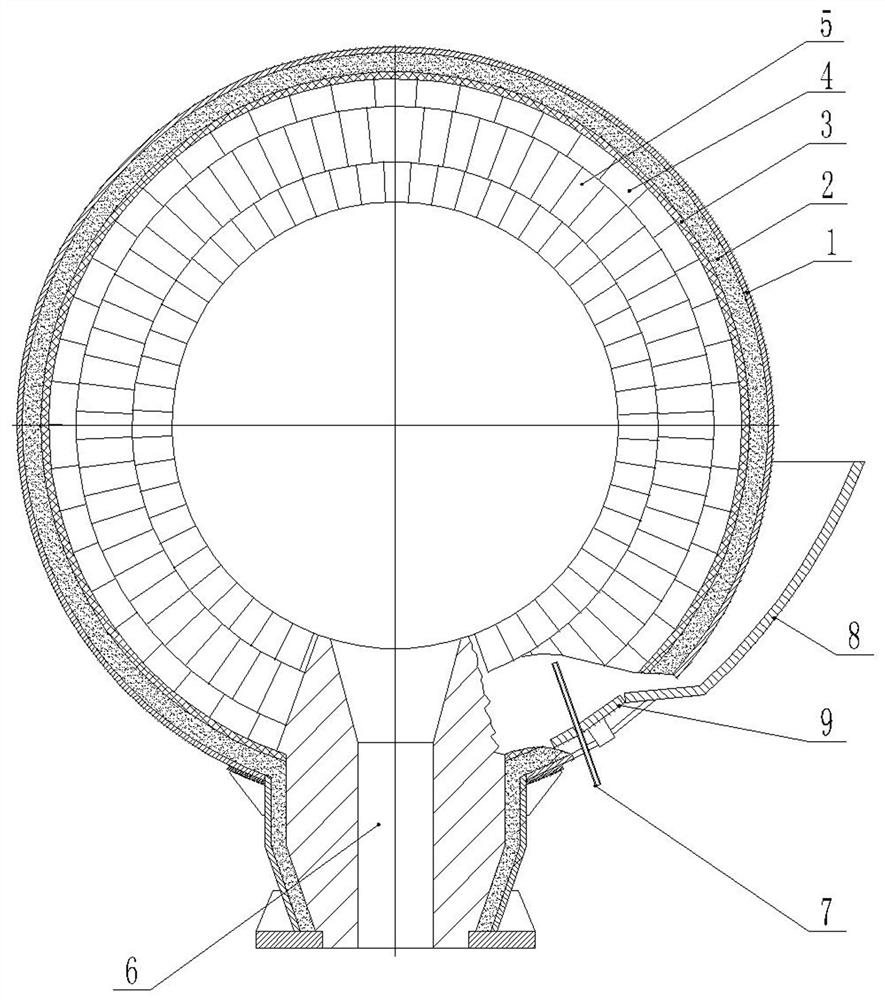

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 As shown, the structure of the hot air enclosure from the outside to the inside is: steel shell 1, spray paint 2, fiber felt 3, clay insulation brick 4, high-alumina insulation brick 5, refractory bricks for the working layer, and the middle of the gooseneck. High-alumina heat-insulating bricks with low refractoriness and weak resistance to burning loss, clay heat-insulating bricks, etc. will burn out after high-temperature gas with a temperature greater than 1100 ° C accumulates in this part for a long time, and form a In large-area hollow areas, after 6 to 12 months of operation, there will be large-scale redness or even burn-through accidents at the joints between the lower part of the casing and the gooseneck, which will cause the blast furnace to shut down and affect production.

[0019] A kind of repairing of the goose neck under the hot bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com