Construction method for adjusting distance between column grids of steel structure

A construction method and steel structure technology, applied to truss structures, columns, pier columns, etc., to achieve the effects of simple and convenient structural construction, good safety and stability, and high structural space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

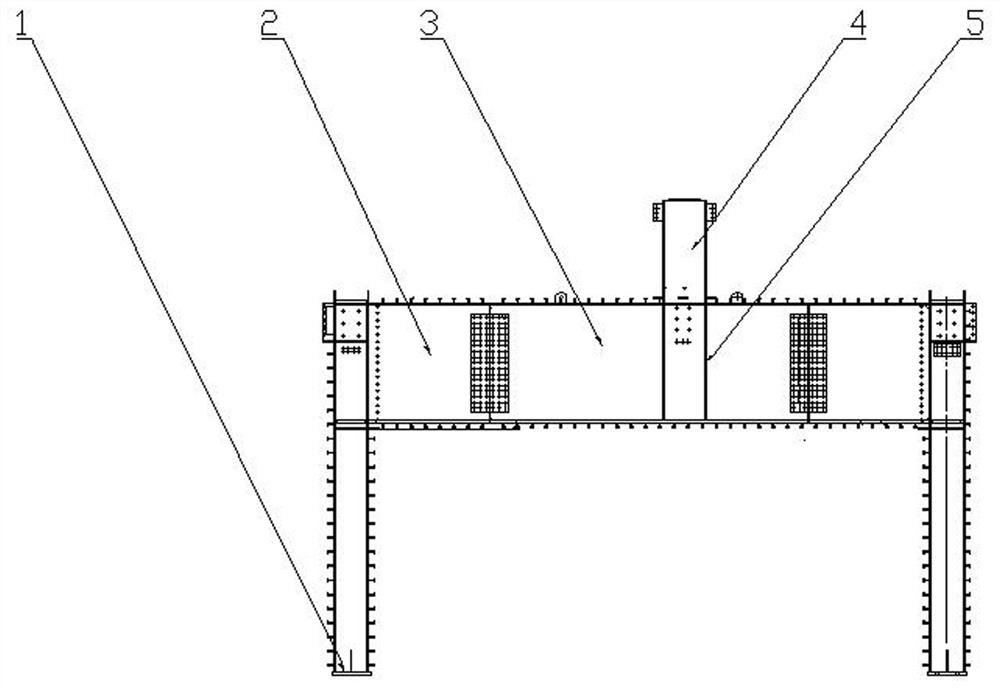

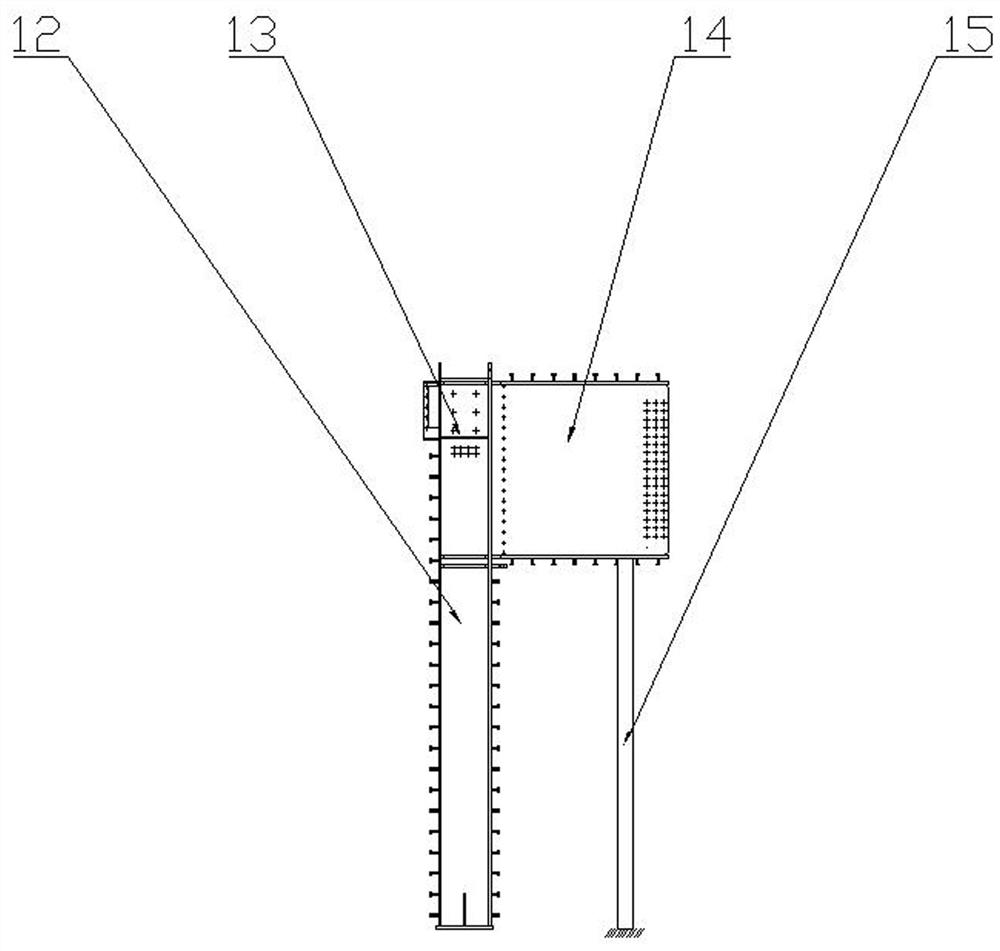

[0027] The steel frame support assembly 2 is composed of a steel frame column 12 and a column-beam connection frame 14 that is welded and fixed to the steel frame beam 3 at the upper end of the steel frame column 12 . When the steel frame column 12 and the column-beam connecting frame 14 are hoisted and welded, the lower end of the column-beam connecting frame 14 is supported by an auxiliary support pipe 15 . The steel bone column 12 adopts I-shaped steel 18, and the welding between the I-shaped steel 18 and the anchor bolts 7 on the concrete floor 1 is performed by the column bottom plate 16, the two sides of the lower part of the I-shaped steel 18 and the upper end surface of the column bottom plate 16 are welded and fixed. reinforcement. Four reinforcing plates 13 are used on the side of the column-beam connecting frame 14 and inside the I-beam 18 to strengthen the connection structure between the column-beam connecting frame 14 and the steel bone column 12 .

[0028] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com