Remote inspection method and remote inspection device based on transparent mine

A transparent and remote technology, applied in design optimization/simulation, instruments, data processing applications, etc., to achieve good promotion value, strong scalability, and ensure the quality of inspections

Inactive Publication Date: 2022-06-10

BEIZHING LONGRUAN TEKNOLODZHIS INK +1

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003]With the increase of mine mining life and the complexity of underground roadway layout, underground safety inspections are faced with problems such as many inspection locations, many inspection equipment, and scattered inspection points. and management staff spend a lot of energy on daily safety inspections

Due to the fact that the inspection task is heavy in the inspection process, it is inevitable that inspections are not inspected, inspections are not comprehensive, inspections are not in-depth, inspection problems are not analyzed, and even inspection records are fabricated. These problems It has brought great hidden dangers to mine safety production

[0004]In recent years, with the gradual improvement of the intelligence level of mines, the environmental monitoring system of the underground workplace, the underground personnel position monitoring system, the underground video monitoring system and the automation of important equipment The traditional on-site inspection cannot use the large amount of data generated by the monitoring and automation subsystem to realize the intelligent inspection, and cannot solve the problems of long inspection time, small scope and shallow inspection depth in the existing inspection. Therefore, it is urgent to use advanced technology to build a remote inspection environment and realize automatic inspection on the ground

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

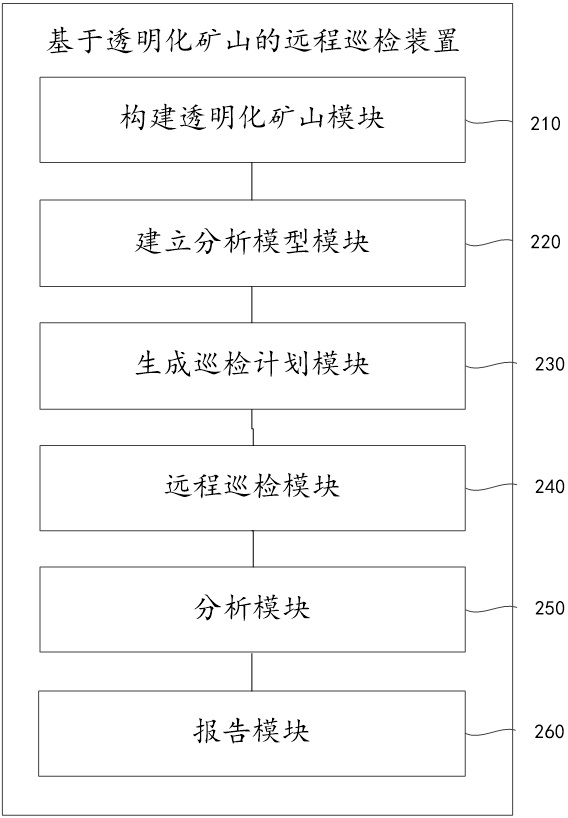

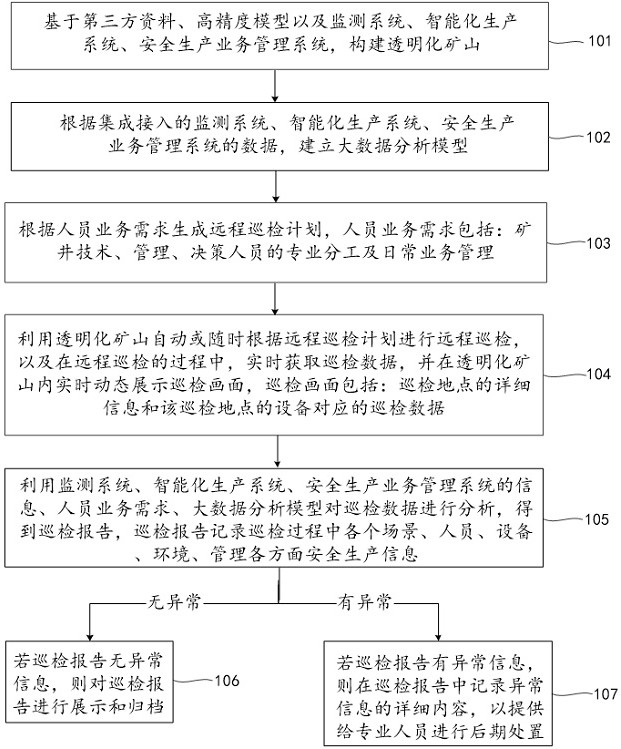

The invention provides a remote inspection method and remote inspection device based on a transparent mine, and relates to the technical field of intelligent inspection above and below a well, and the method comprises the steps: building a high-precision visual and dynamically corrected transparent mine covering production places above and below the well; establishing an inspection big data analysis model for inspection process analysis and inspection report generation; mine technology, management and decision makers determine an inspection plan according to professional division of labor and daily management requirements, and when the inspection equipment is approached in the inspection process, the system automatically pops up equipment monitoring, environment monitoring and other data; after inspection is finished, an inspection report document is automatically generated; and carrying out cooperative command and on-site disposal on abnormal information in the inspection report. The system can replace a traditional on-site inspection mode of a mine, solves the problem that traditional inspection is limited by time and personnel, has the characteristics of real-time multi-line immersive inspection and disposal, and avoids the defects that traditional manual well descending takes long time and is single in line.

Description

technical field [0001] The invention relates to the technical field of intelligent inspection in underground mines, in particular to a remote inspection method and a remote inspection device based on a transparent mine. Background technique [0002] Mine underground inspection is an important part of mine daily safety management. At present, the method of mine underground inspection is still based on personnel on-site inspection. Inspection personnel use traditional pen and paper to record problems and check the main content It includes the operation of equipment, environmental monitoring of production sites, hidden dangers of production sites, and personnel violations. The locations include substations, water pump rooms, main ventilator rooms, mining working faces, and tunneling working faces, etc. [0003] With the increase of mine mining life and the complexity of underground roadway layout, underground safety inspections are faced with problems such as multiple inspectio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G06Q10/06G06F30/20G06F30/13G06Q50/02G06Q50/08G06T17/05

CPCG06Q10/0637G06Q50/02G06Q50/08G06F30/20G06F30/13G06T17/05

Inventor 毛善君雷贵生景超黄伟薛国华李祥张兵陈金川胡宝锋

Owner BEIZHING LONGRUAN TEKNOLODZHIS INK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com