Method for improving assembly rate and quality of assembly type shear wall concrete building

A concrete and prefabricated technology, which is applied in the processing of building materials, construction, building components, etc., can solve problems such as difficult quality control, complicated construction technology, and structural hidden dangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

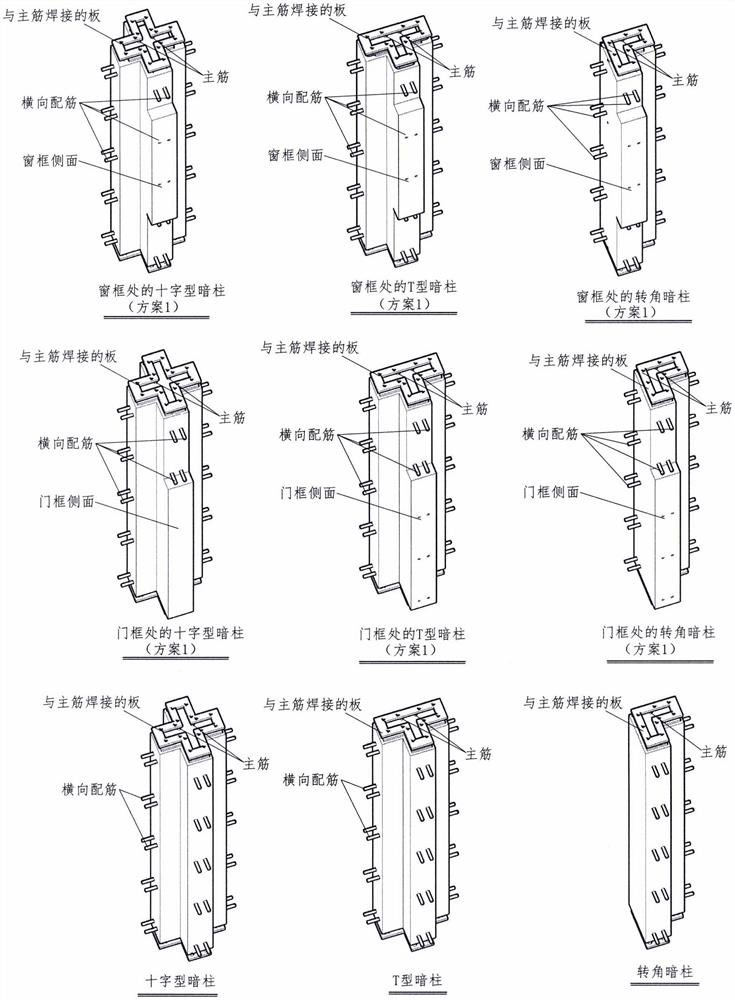

[0017] Below, in conjunction with the accompanying drawings, describe in detail how to implement house building according to the method of the present invention:

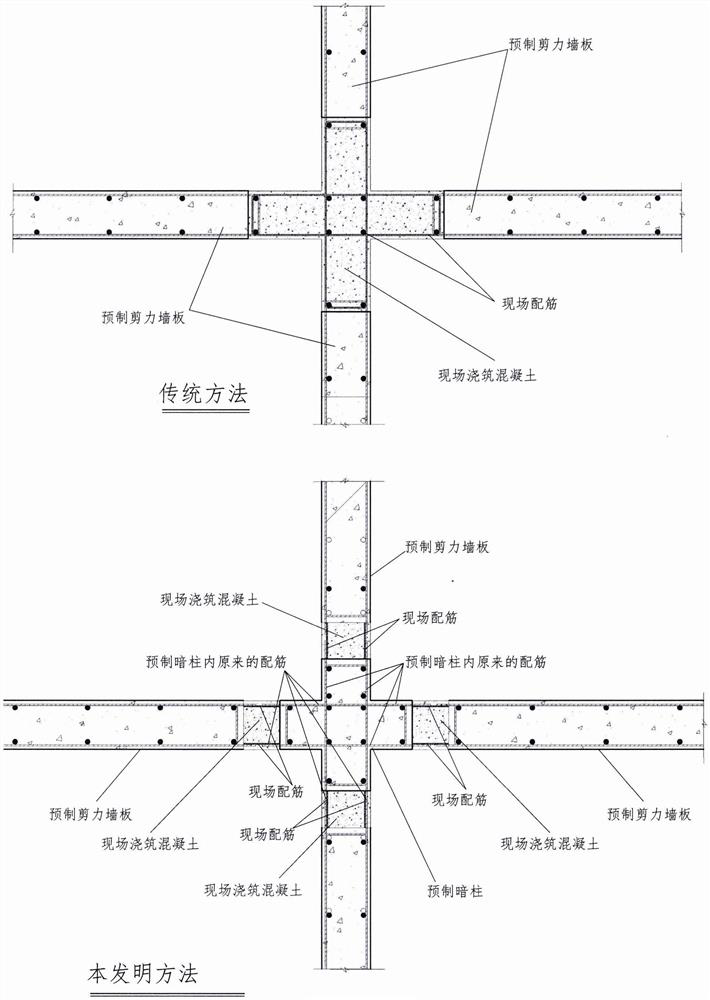

[0018] figure 1 seen in:

[0019] In the connection of the wall above the figure, in the traditional method, in order to reduce the interference of the walls in different directions, the work of bundling the steel bars on site is more difficult. The distance increases the workload of on-site concrete construction.

[0020] In the method used for the connection of the walls below the figure, the present invention uses prefabricated hidden columns to connect the walls, and the work of on-site connection is very simple: the work of on-site reinforcement is simply to extend the hidden columns and the side of the wall. The steel bars are connected to each other, and the concrete at the joint is poured to complete the work of connecting the dark column and the wall on the same floor.

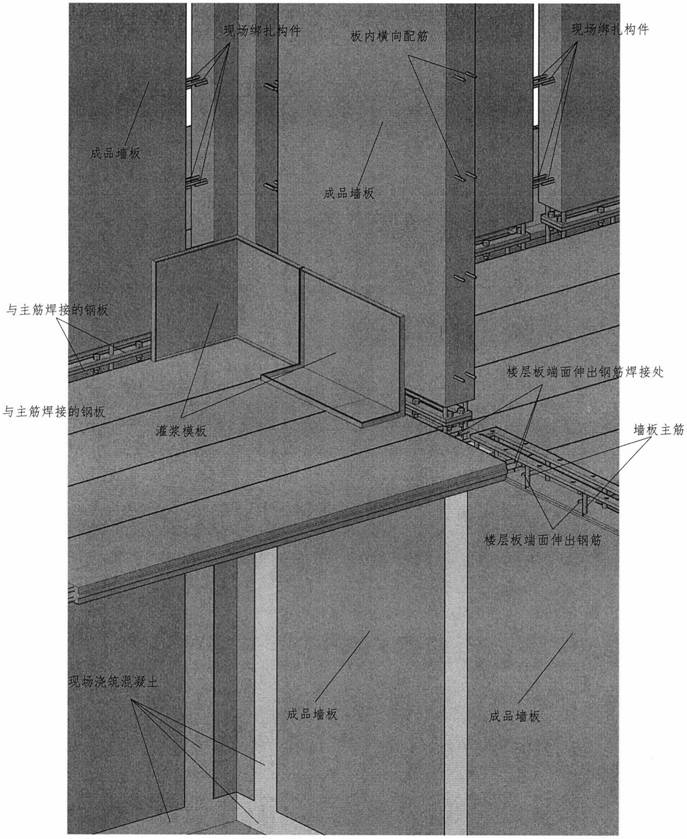

[0021] exist figure 2 seen in: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com