Single-well zipper type fracturing gas testing construction method

A construction method and zipper-type technology, which are applied in earth-moving drilling, wellbore/well components, and production fluids, etc., can solve the problem of high cost of single-well reverse drainage sewage treatment, insufficient flowback energy in atmospheric gas reservoirs, and reservoir formation. Water damage and other problems, to achieve the effect of significantly speeding up, shortening the construction period, and reducing water damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method of the present invention is further explained below in conjunction with the accompanying drawings:

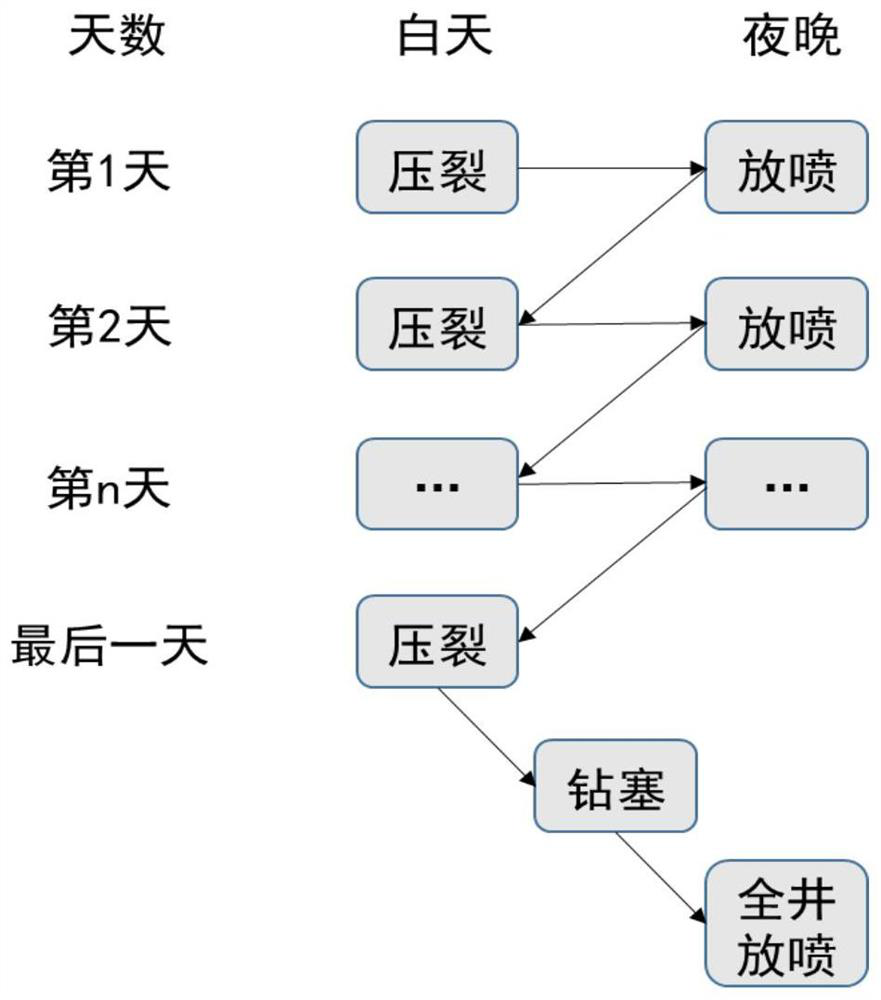

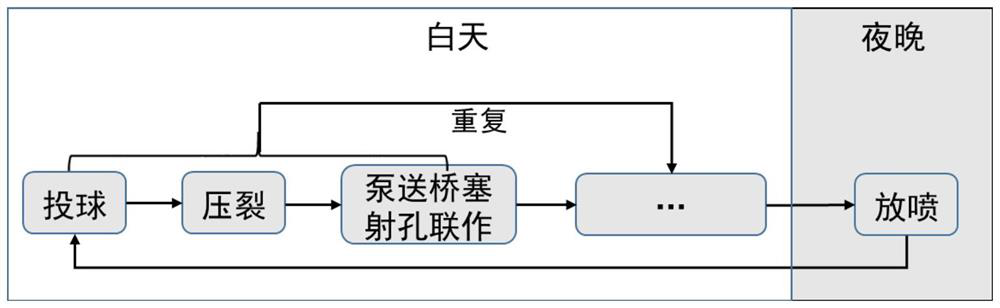

[0018] see figure 1 , the present invention includes a fracturing period and a blow-out period, wherein during the fracturing period, multi-stage fracturing operations are performed during the day, and blow-out operations are performed at night, and the two are alternately performed. In the whole well blowout period, when the production is stable, the whole well blowout period ends.

[0019] Among them, the flowback fluid from the venting and blowing operation the night before was collected, and the fracturing fluid was prepared and used during the multi-stage fracturing operation the next day; after the last stage of the fracturing operation during the day, the pumping perforation bridge-plug combined operation was performed, and then The night blowing operation is carried out without casting the bridge plug ball; after the night blowing operation is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com