Method for erecting bridge body

A beam body and bridge technology, applied in the field of bridge construction, can solve the problems of resource waste, high cost, low utilization rate of beam moving machines and beam lifting machines, etc., and achieve the effects of improving efficiency and reducing the difficulty and cost of land acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

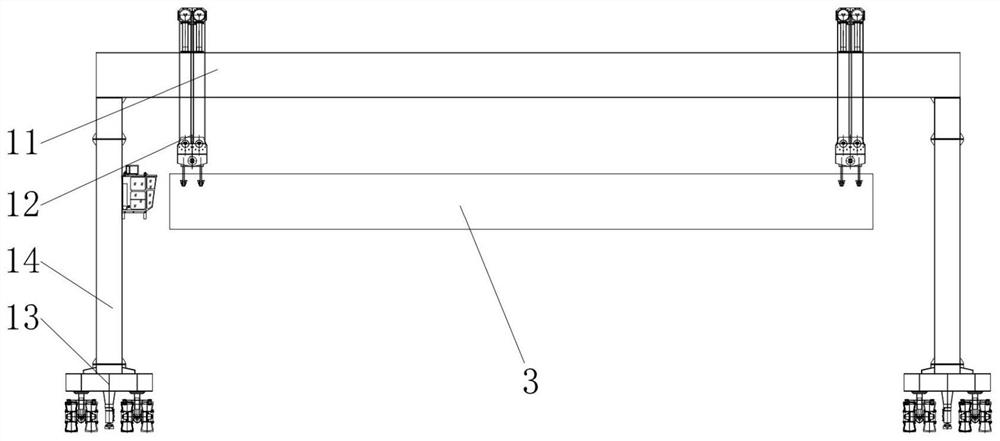

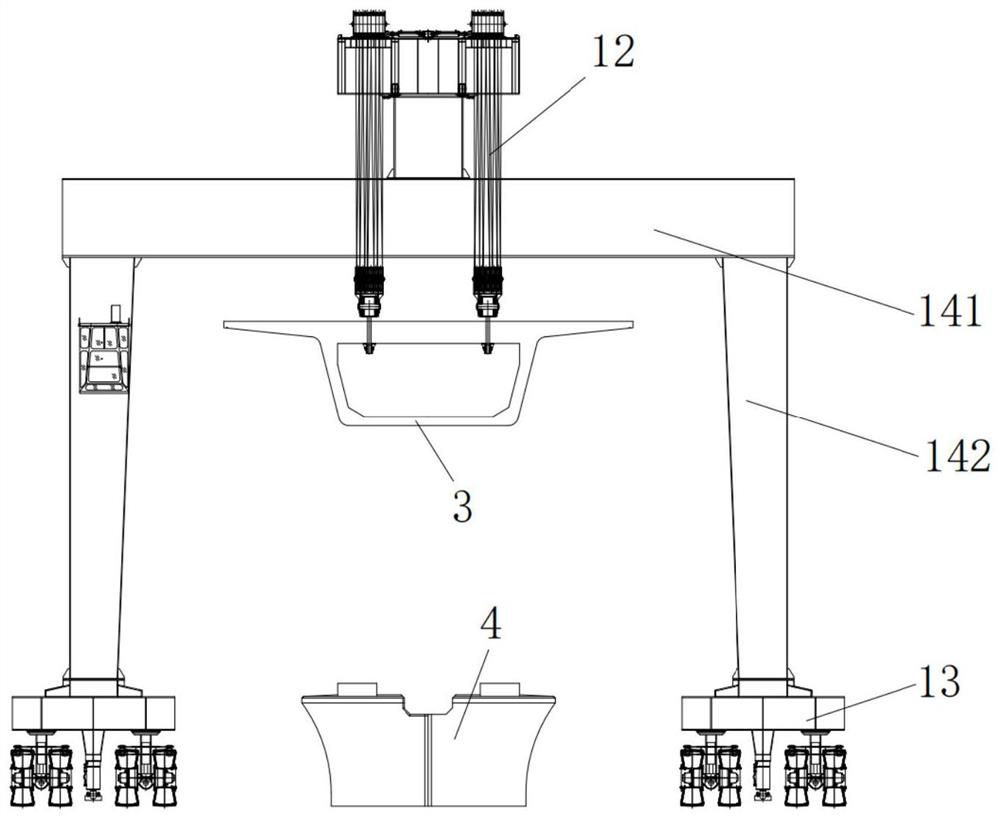

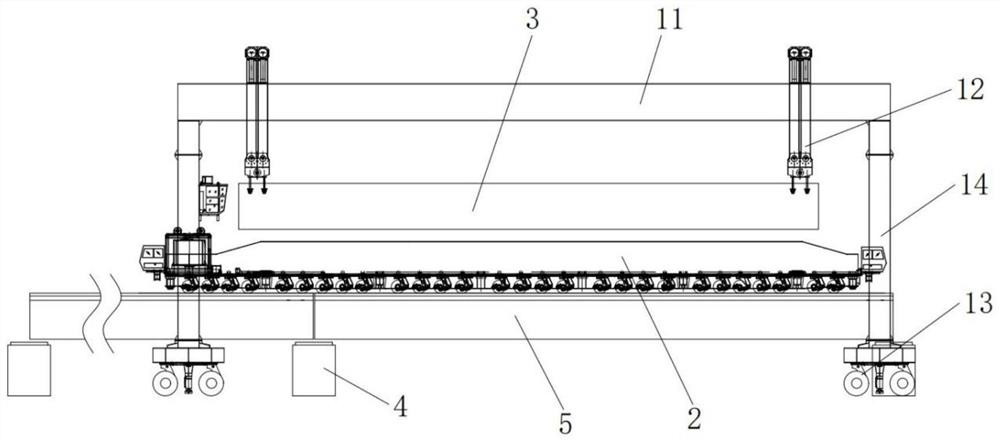

[0040] In order to more clearly understand the above objects, features and advantages of the present disclosure, the solutions of the present disclosure will be further described below. It should be noted that the embodiments of the present disclosure and the features in the embodiments may be combined with each other under the condition of no conflict.

[0041] Many specific details are set forth in the following description to facilitate a full understanding of the present disclosure, but the present disclosure can also be implemented in other ways different from those described herein; obviously, the embodiments in the specification are only a part of the embodiments of the present disclosure, and Not all examples.

[0042] In the construction of railway transportation infrastructure, bridge construction is often the key control project of the entire construction project. In particular, the high-speed railway bridges in my country account for a large proportion of the enti...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap