Construction process for double-line large-section split lining trolley in underground excavation section of subway

A technology for lining trolleys and construction technology, which is applied in wellbore lining, tunnel lining, underground chambers, etc., can solve the problems of multiple assembly time, space and process conversion limitations, and difficulty in settlement control, so as to reduce the risk of safety accidents, The effect of reducing artificial consumption and controlling surface subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

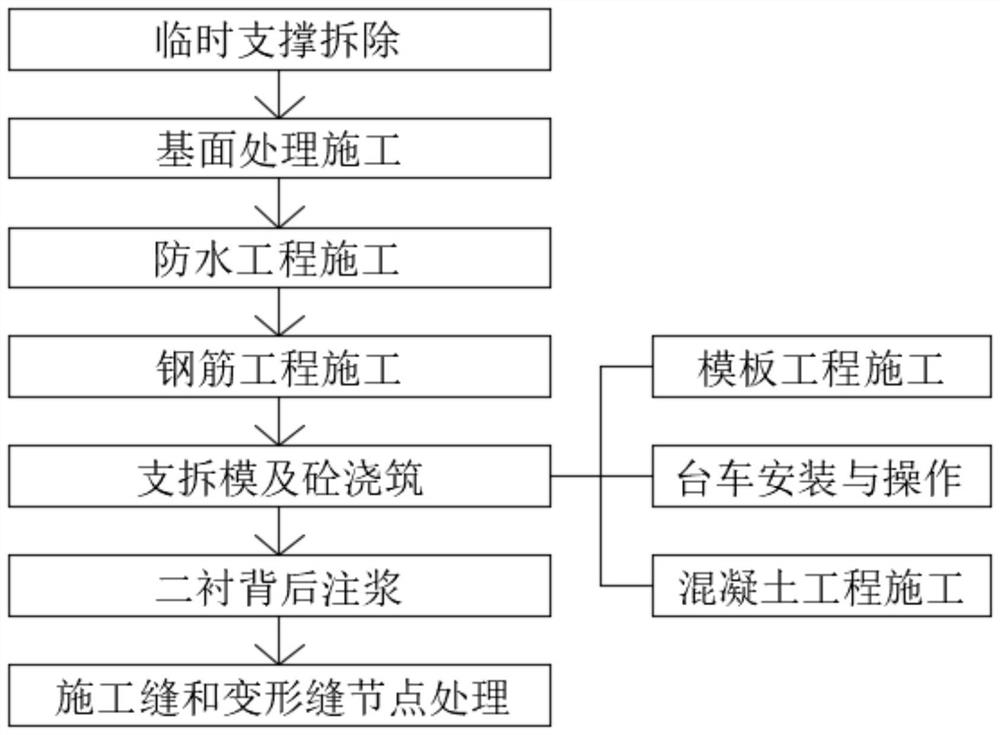

[0073] see figure 1 , a construction process for a double-line large-section split lining trolley in a subway underground excavation section, comprising the following steps

[0074] Step 1, the temporary support is removed, according to the construction progress and the overall construction organization arrangement, the temporary inverted arch and the temporary middle wall are removed, and the temporary inverted arch and the temporary middle wall are removed in sequence according to the construction requirements, and the temporary support is removed first. Do the test section to observe the settlement of the vault. After the temporary support of the CRD method and the double-side guide pit method, the vault settlement should not exceed 10mmn and reach stability. The longitudinal removal length can be appropriately increased according to the monitoring data;

[0075] Step 2: Base surface treatment construction, the initial support is closed into a ring, and the vault settlement...

Embodiment 2

[0096] see figure 1 , a construction process for a double-line large-section split lining trolley in a subway underground excavation section, comprising the following steps

[0097] Step 1, the temporary support is removed, according to the construction progress and the overall construction organization arrangement, the temporary inverted arch and the temporary middle wall are removed, and the temporary inverted arch and the temporary middle wall are removed in sequence according to the construction requirements, and the temporary support is removed first. Do the test section to observe the settlement of the vault. After the temporary support of the CRD method and the double-side guide pit method, the vault settlement should not exceed 10mmn and reach stability. The longitudinal removal length can be appropriately increased according to the monitoring data;

[0098] Step 2: Base surface treatment construction, the initial support is closed into a ring, and the vault settlement...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com