Internal compression solid-liquid separation device for intelligent sweeper

A technology for solid-liquid separation and cleaning vehicles, applied in separation methods, filtration separation, presses, etc., can solve the problems of no separation, reducing the effect of solid-liquid separation of garbage, secondary pollution, etc., to facilitate storage and recycling, improve Recovery efficiency, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

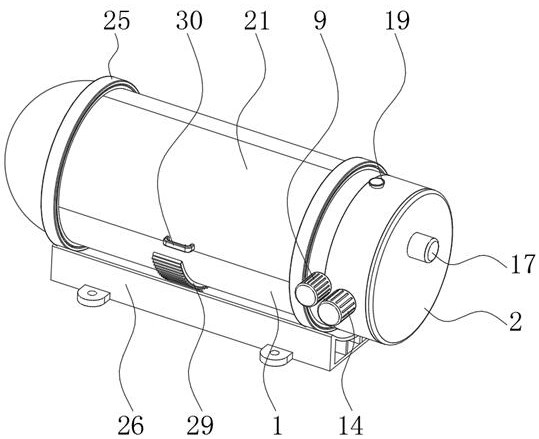

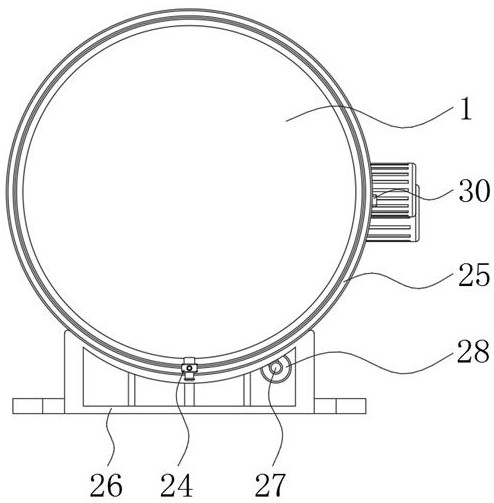

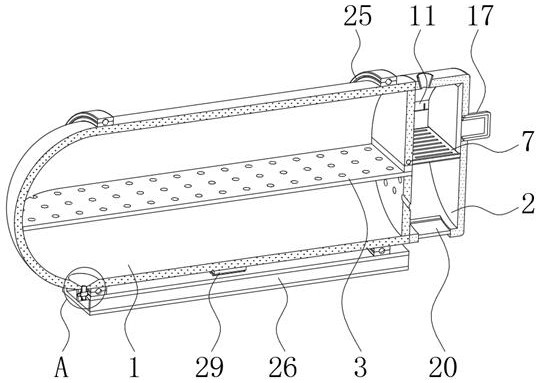

[0031] Wherein, the left and right ends of the outer surface of the recovery bucket 1 are fixedly sleeved with support bearings 25, the number of support bearings 25 is two, and the bottoms of the two support bearings 25 are fixedly connected with support frames 26, and the support frames 26 are fixedly installed by bolts. Inside the garbage truck, by setting the support bearing 25, it can be ensured that the support frame 26 can support the recycling bin 1 as a whole, so that the recycling bin 1 can be fixed in the garbage truck as a whole through the supporting bracket 26, and the driving motor can also be ensured. 27. The driving of the driving gear 28 and thus the tooth pressure plate 29 can make the recovery bucket 1 rotate under the cooperation of the support bearing 25 .

[0032] Wherein, the middle part inside the support frame 26 is fixedly installed with a drive motor 27, and the other end of the output shaft of the drive motor 27 is fixedly sleeved with a drive gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com