A clamping mechanism for steel bar sawing CNC machine

A technology of clamping mechanism and numerical control machine, which is applied in the direction of clamping, metal processing machinery parts, manufacturing tools, etc. It can solve the problems of affecting the cutting accuracy of steel bars, uneven steel bars, and easy shaking, so as to reduce adjustment and reduce unevenness of steel bars. Neatness and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

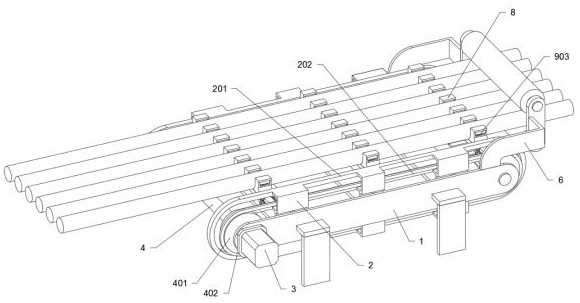

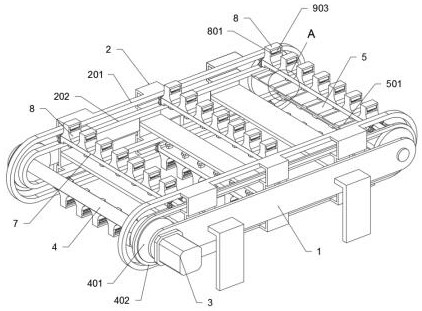

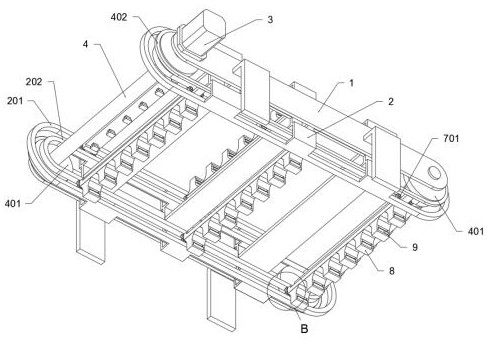

[0037] Example: please refer to Figure 1 to Figure 11 :

[0038]The present invention proposes a clamping mechanism for a CNC machine for sawing steel bars, which includes an outer support plate 1; an inner circulation guide frame 2 is fixedly connected to the inner surface of the outer support plate 1 by welding, and the inner circulation guide frame 2 includes a circulation outer guide frame 2. The rail 201 and the inner circulating rail 202, the outer support plate 1 is provided with two places, and the middle of the two outer support plates 1 is fixedly connected by a connecting rod; the driving motor 3, the main body of the driving motor 3 is fixedly connected to the front right side of the outer support plate 1 by screws side, and the output end of the drive motor 3 is connected to and drives the pulling assembly; the pulling assembly is composed of two sets of synchronous pulling shafts 4, and the two ends of the synchronous pulling shafts 4 are respectively connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com