Sand storage device for high-precision sand shooting machine

A sand-shooting machine with high-precision technology, which is applied to the used abrasive processing device, abrasive feeding device, metal processing equipment, etc., can solve the problems of poor practicability, tedious operation of replacing fine sand with each other, and achieve easy operation. , easy to switch between each other and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

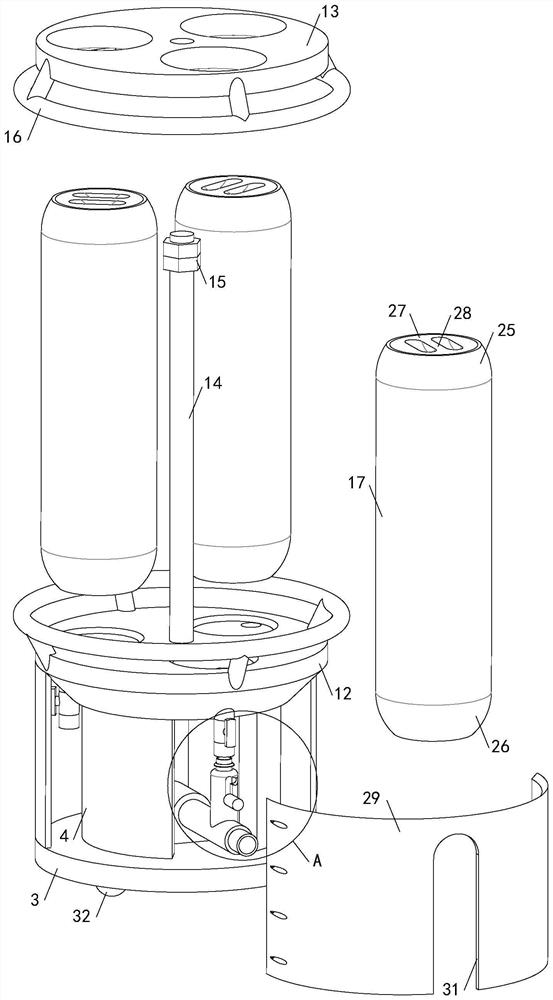

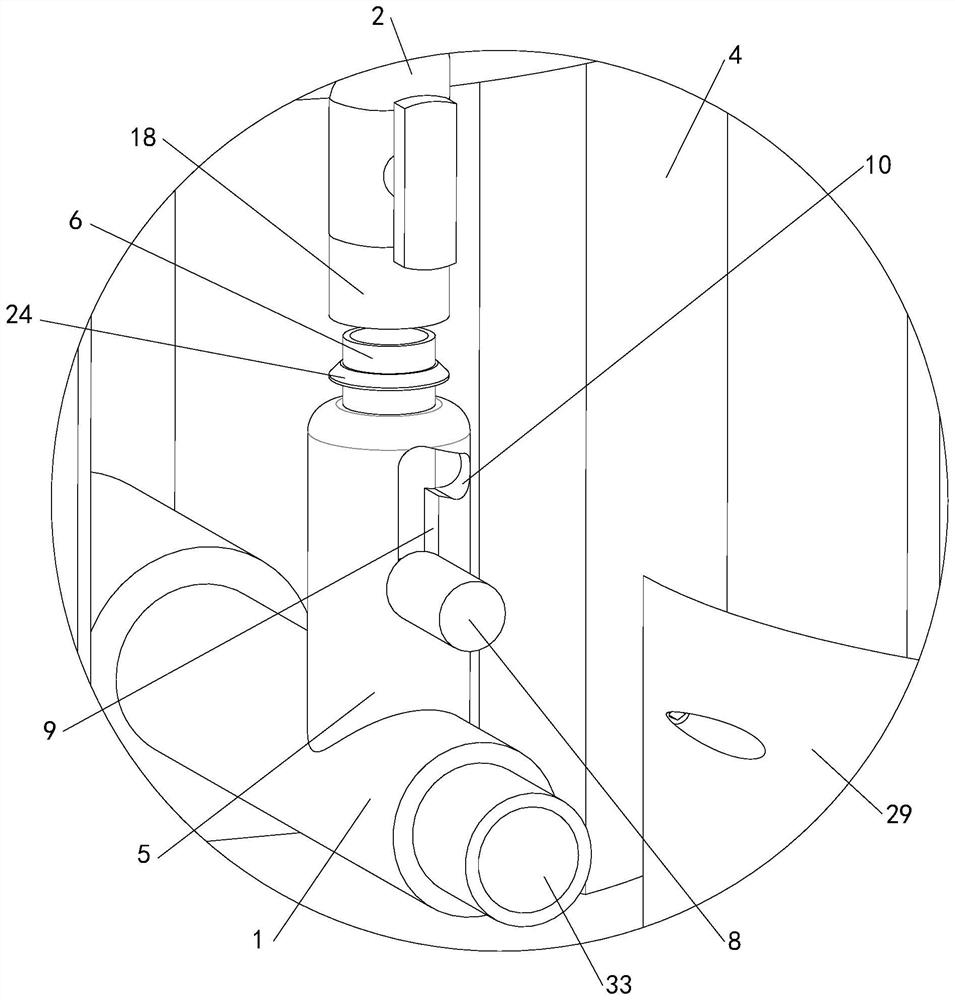

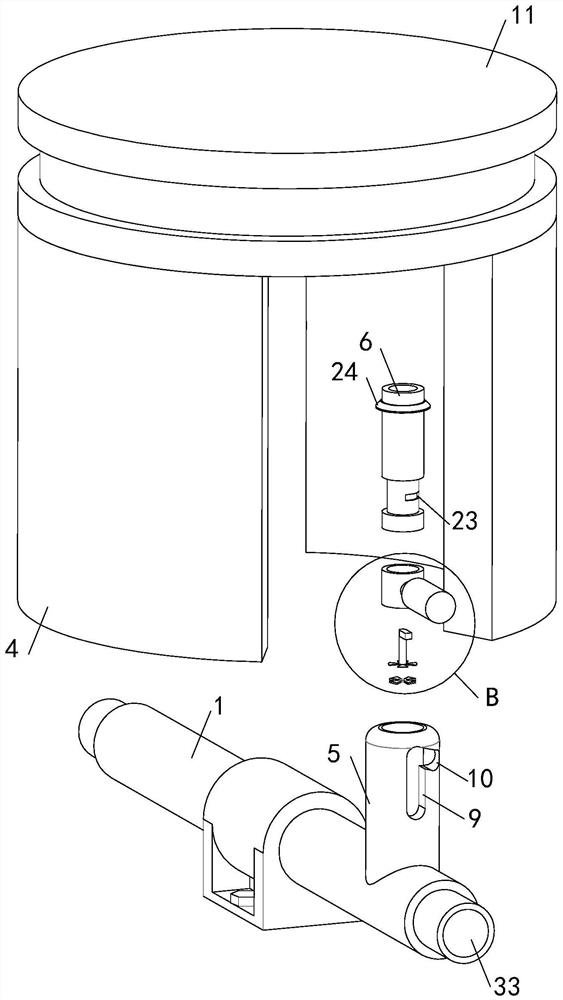

[0031] see Figure 1-6 , a sand storage device for a high-precision sand-shooting machine, comprising a high-pressure jet pipe 1 and a plurality of guide pipes 2, also comprising a chassis 3, and the bottom end of the chassis 3 is equipped with a plurality of ball wheels 32, so that the chassis 3 is convenient for For movement adjustment, the top of the bottom frame 3 is fixedly connected with two C-shaped plates 4 , the high-pressure jet pipe 1 is installed on the top of the bottom frame 3 , and the high-pressure jet pipe 1 is located between the two C-shaped plates 4 , and the bottom frame 3 is provided with There is a skin system. The skin system includes two C-shaped sheet metal plates 29 that are assembled and installed by bolts, so as to facilitate the protection of the components installed between the chassis 3 and the installation bottom plate 12. The two C-shaped sheet metal plates 29 are respectively provided with a passage port 30 and an adjustment port 31, to reali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com