Gold stamping roll placing mechanism and gold stamping machine

A technology of unwinding mechanism and gold coil, which is applied in the direction of winding strips, thin material handling, transportation and packaging, etc. It can solve cumbersome problems, achieve the effects of reducing replacement steps, reducing demand, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

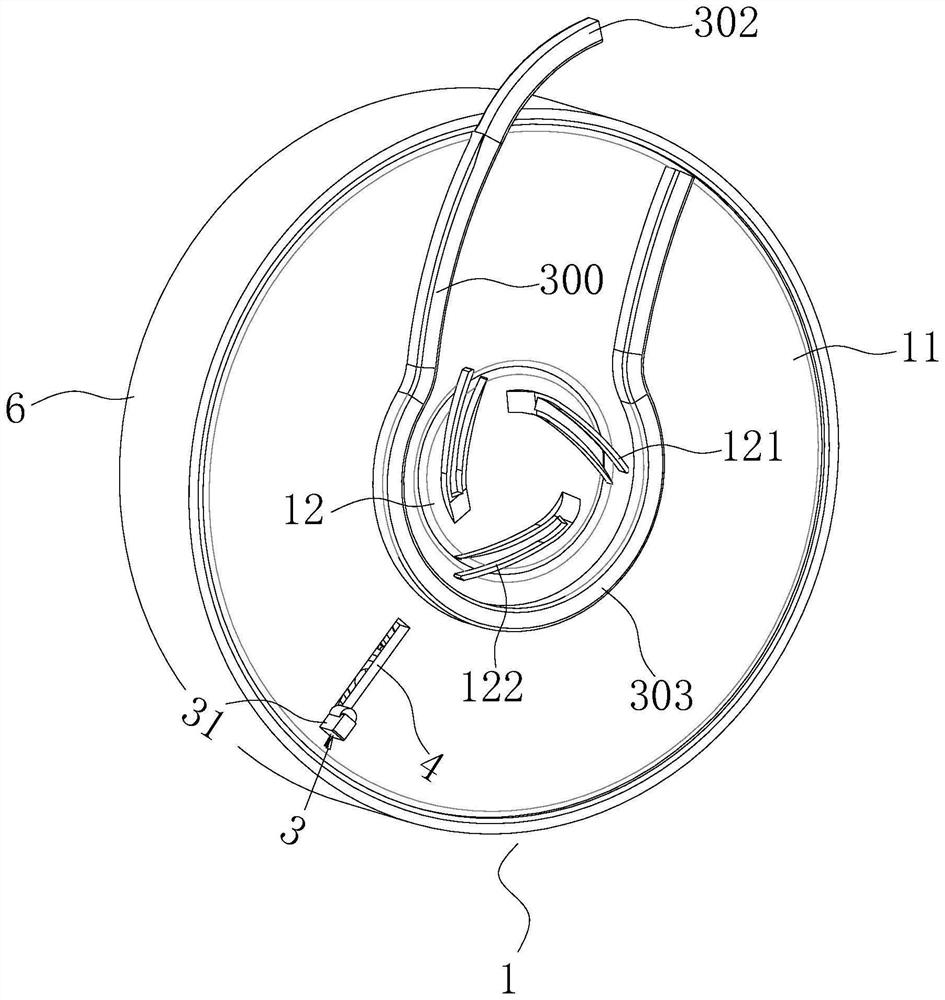

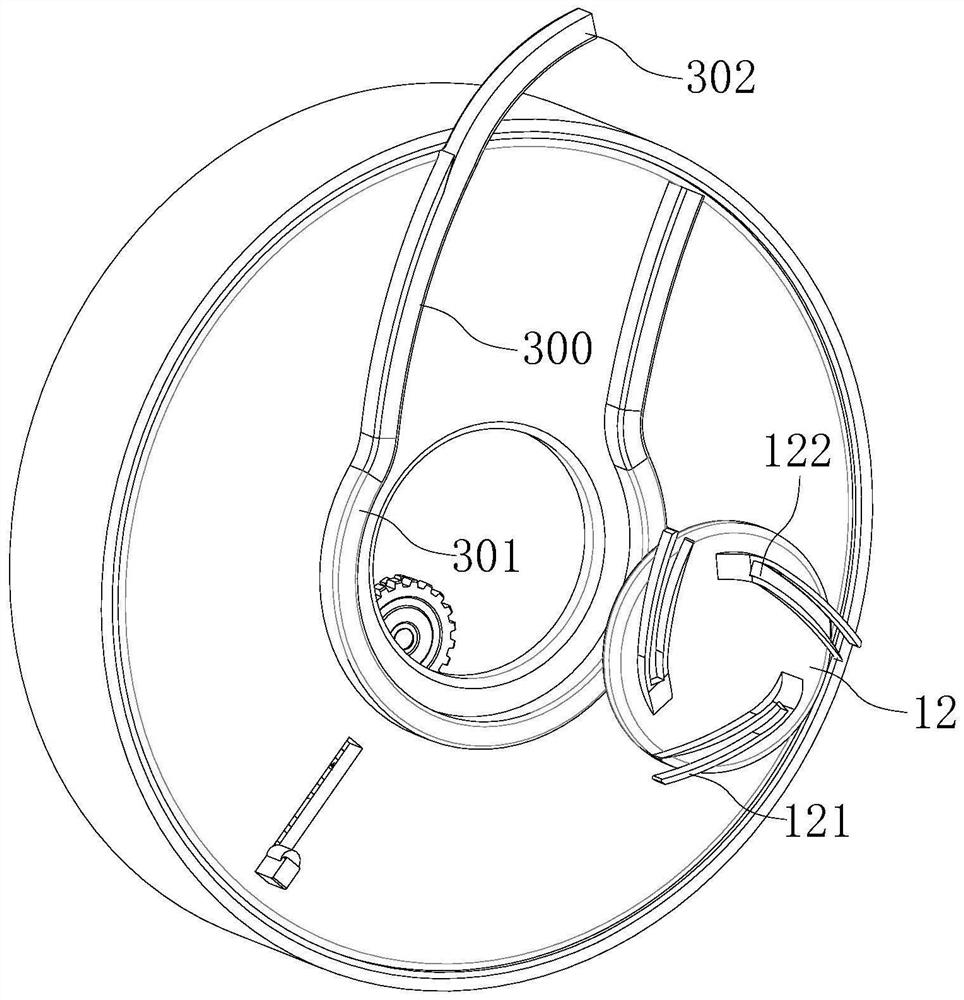

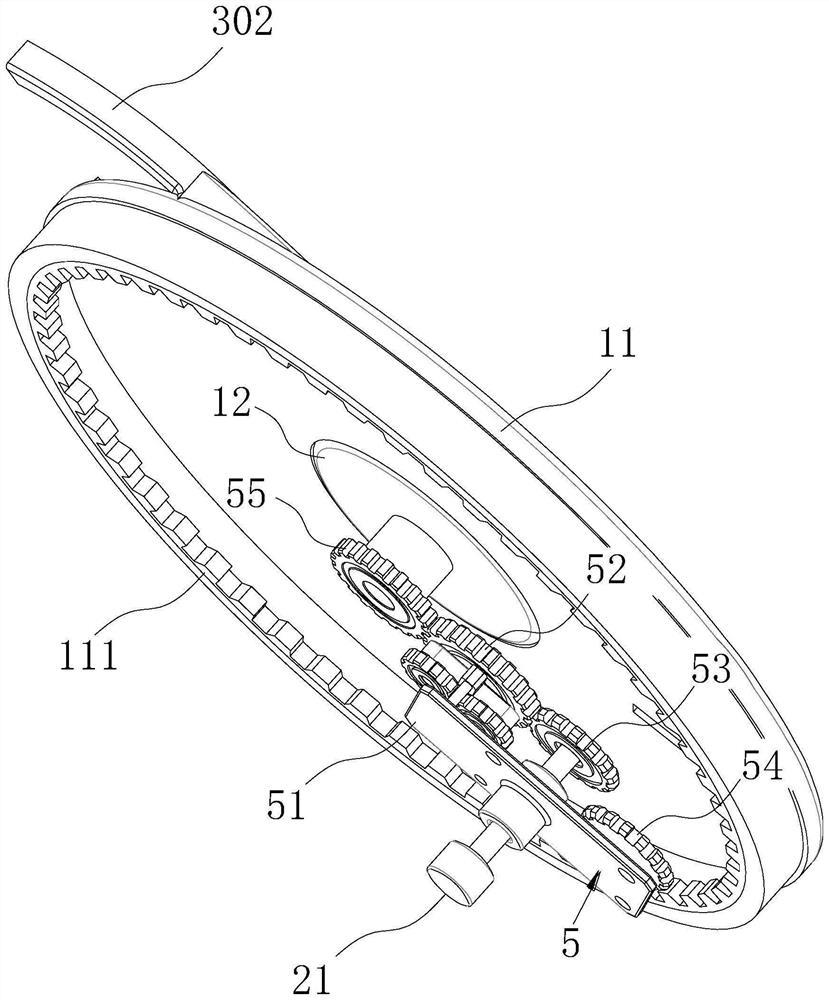

[0037] like Figure 1-10 As shown, a hot stamping roll placement mechanism and a hot stamping machine include an unwinding mechanism 1, which includes a movably arranged feeding tray body 11, and a guiding portion 300 is provided on the feeding tray body 11, and one end of the guiding portion 300 is provided with a The bracket part 301 of the axis of the feeding tray body 11 and the other end are provided with an arc-shaped part 302 extending to the outside of the feeding tray body 11;

[0038] It also includes a bracket set horizontally and used for placing the hot stamping roll. The feeding disc body 11 is driven to rotate once, and completes the following two stations during its stroke:

[0039] In the first station, the outlet of the guide part 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com