Rare earth heat stabilizer for high-transmittance PVC (polyvinyl chloride) product and preparation method of rare earth heat stabilizer

A rare earth heat stabilizer and product technology, which are applied to the rare earth heat stabilizer of high-permeability PVC products and the field of preparation thereof, can solve the problems of reducing production cost, complicated process and high cost, and achieve the purpose of reducing production cost, simplifying process steps, improving stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

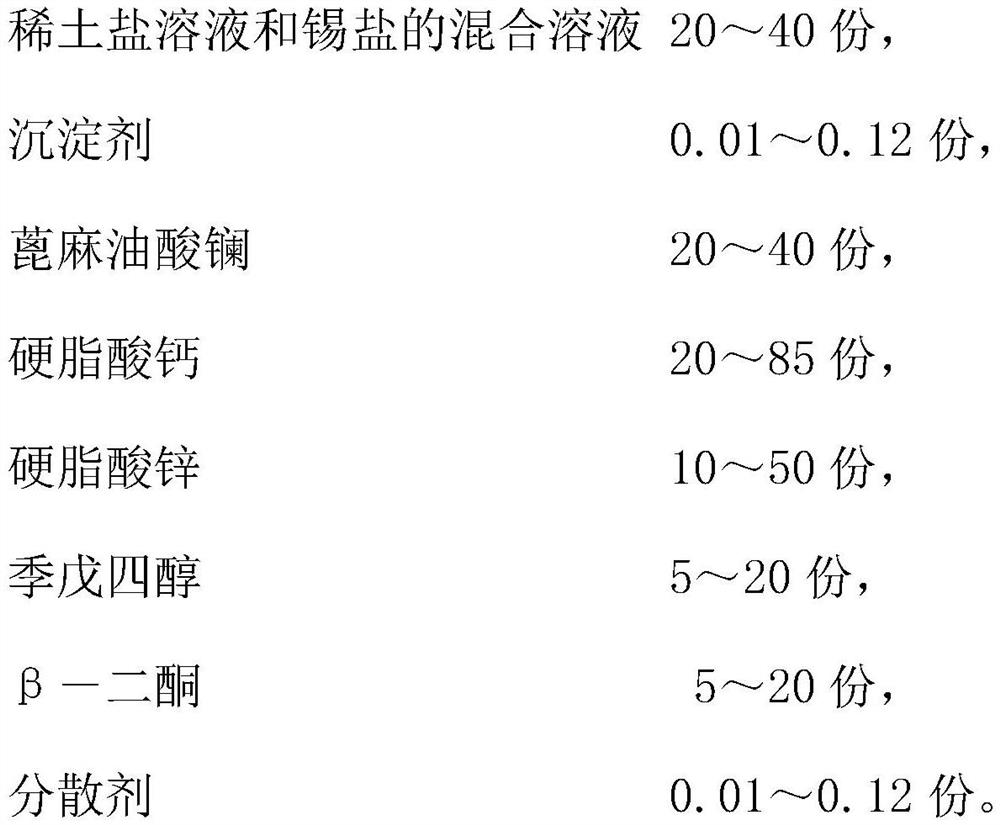

[0024] A rare earth heat stabilizer for high-permeability PVC products is composed of the following raw materials and parts by weight of the raw materials:

[0025]

[0026] The ion concentration of rare earth ions in the mixed solution of the rare earth salt solution and the tin salt is 1.25 mol / L.

[0027] The rare earth salt solution in the mixed solution of the rare earth salt solution and the tin salt is an acetate salt solution obtained by dissolving the rare earth salt in water.

[0028] The rare earths in the mixed solution of the rare earth salt solution and the tin salt are scandium and yttrium.

[0029] The precipitating agent is sodium hydroxide solution.

[0030] The dispersant is sodium lauryl sulfate.

[0031] A preparation method of a rare earth heat stabilizer for high-permeability PVC products is realized by the following steps:

[0032] Step 1, using rare earth salt solution and tin salt as raw materials, to prepare a mixed solution...

Example Embodiment

[0036] Embodiment 2

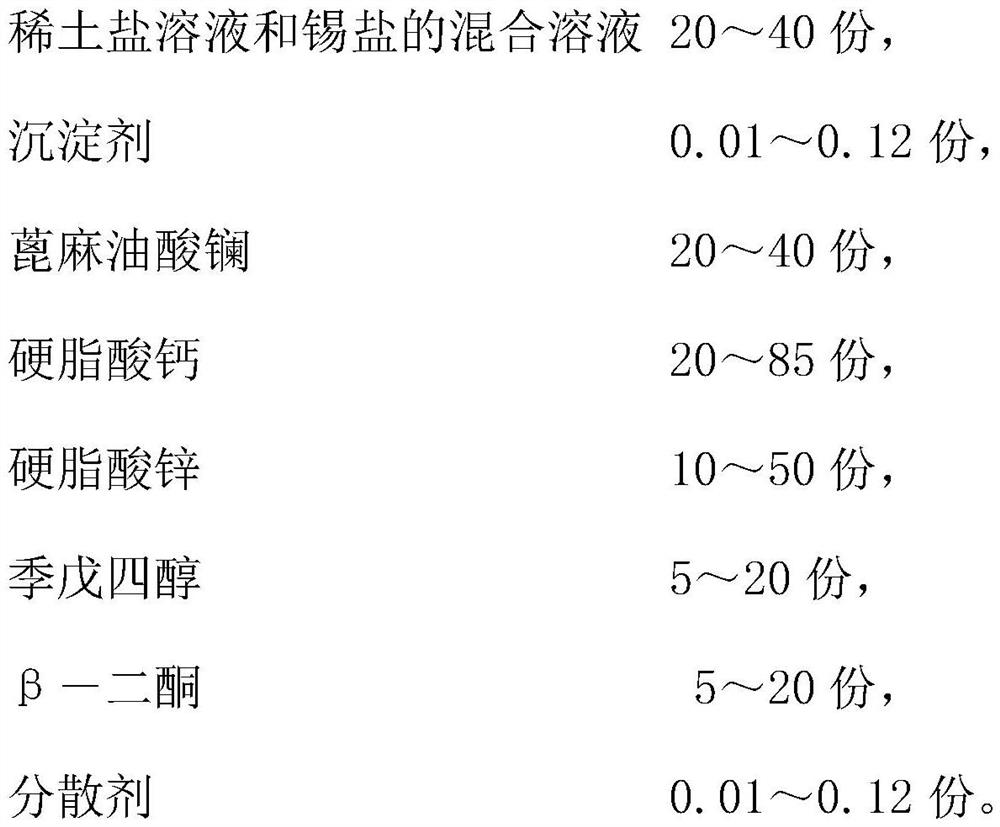

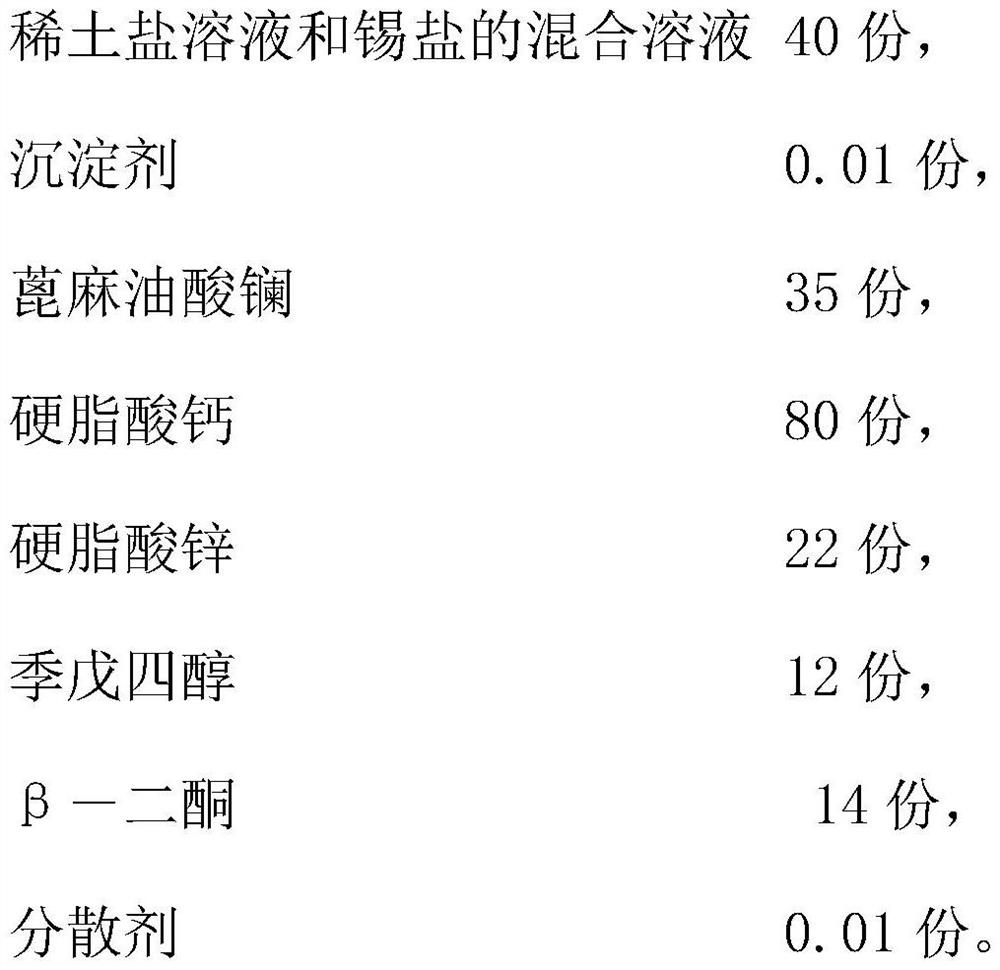

[0037] A rare earth heat stabilizer for high-permeability PVC products is composed of the following raw materials and parts by weight of the raw materials:

[0038]

[0039] The ion concentration of rare earth ions in the mixed solution of the rare earth salt solution and the tin salt is 2.00 mol / L.

[0040] The rare earth salt solution in the mixed solution of the rare earth salt solution and the tin salt is a nitrate solution obtained by dissolving the rare earth salt in water.

[0041] The rare earths in the mixed solution of the rare earth salt solution and the tin salt are scandium and yttrium.

[0042] The precipitating agent is sodium hydroxide solution.

[0043] The dispersant is sodium lauryl sulfate.

[0044] A preparation method of a rare earth heat stabilizer for high-permeability PVC products is realized by the following steps:

[0045] Step 1, using rare earth salt solution and tin salt as raw materials, to prepare a mixed solution wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap