Preparation method of intermediate alloy for R60705 zirconium alloy cast ingot

A master alloy and zirconium alloy technology, which is applied in the field of preparation of master alloy for R60705 zirconium alloy ingot casting, can solve the problems of low degree of homogenization and low addition content, so as to avoid high-density inclusions, improve homogenization, and promote uniformity the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment includes the following steps:

[0026] Step 1. Clean up the processing site to prevent foreign matter from entering, use a lathe to turn the Nb bar into chips with a thickness × width × length of (0.5mm±0.1mm) × (5mm±1mm) × Lmm, and then manually screen and cut To the length of 25mm ~ 35mm, then put it into a V-type mixer, add ethanol to clean, and place it in an oven to dry at 80 ° C for 60 minutes to obtain Nb chips; the chemical composition of the Nb rod is shown in Table 1 below;

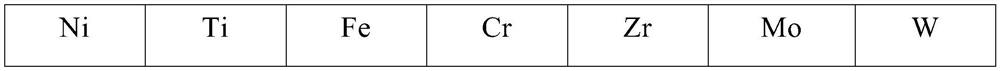

[0027] Chemical composition (wt%) of Nb rods in Table 1 Example 1

[0028]

[0029]

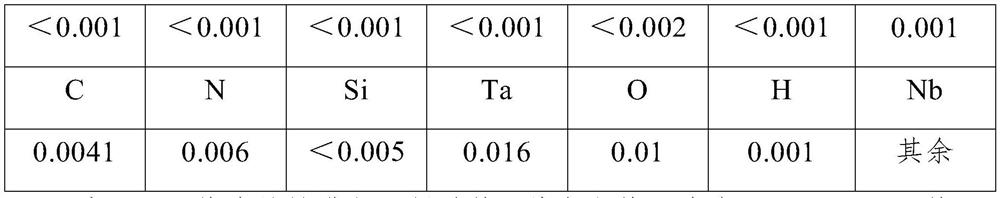

[0030]Step 2, carry out double-layer sieving of sponge zirconium, wherein the size of the upper sieve is φ12.4mm, and the size of the lower sieve is φ6mm, to obtain particles with a particle size of 3mm to 12.4mm, and then manually select the abnormal surface color material that affects the use ( Blue and yellowish, etc.) and hard lumps to obtain zirconium sponge for use; the chemi...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] Step 1. Clean up the processing site to prevent foreign matter from entering, use a lathe to turn the Nb bar into chips with a thickness × width × length of (0.5mm±0.1mm) × (5mm±1mm) × Lmm, and then manually screen and cut To the length of 25mm~35mm, put it into a V-type mixer, add ethanol to clean, place it in an oven and dry it at 100°C for 40min to obtain Nb chips; the chemical composition of the Nb rod is shown in Table 1 in Example 1. ;

[0042] In step 2, the sponge zirconium is subjected to double-layer sieving, wherein the size of the upper sieve is φ9mm, and the size of the lower sieve is φ3mm, so as to obtain particles with a particle size of 3mm to 9mm, and then manually select the abnormal surface color material (blue hair) that affects the use. Huang etc.) and hard block material, obtain the zirconium sponge for use; the chemical composition of the zirconium sponge is as shown in Table 2 in Example 1; ...

Embodiment 3

[0050] This embodiment includes the following steps:

[0051] Step 1. Clean up the processing site to prevent foreign matter from entering, use a lathe to turn the Nb bar into chips with a thickness × width × length of (0.5mm±0.1mm) × (5mm±1mm) × Lmm, and then manually screen and cut To the length of 25mm ~ 35mm, then put it into a V-type mixer, add ethanol to clean, and place it in an oven to dry at 90 ° C for 50 min to obtain Nb chips; the chemical composition of the Nb rod is shown in Table 5 below;

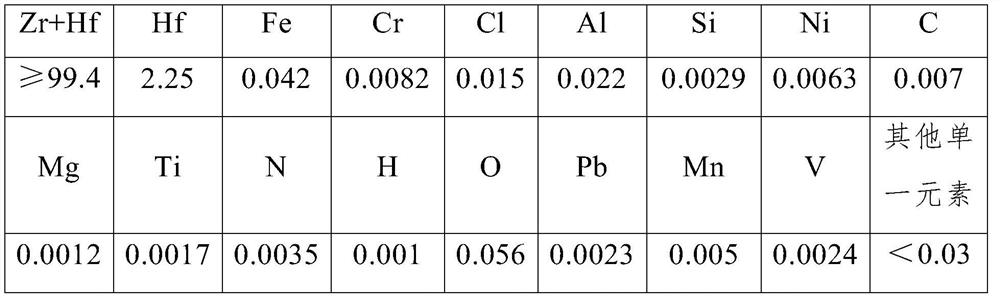

[0052] The chemical composition (wt%) of Nb rod in table 5 embodiment 3

[0053] Ni Ti Fe Cr Zr Mo W <0.001 0.001 <0.001 <0.001 <0.001 <0.001 <0.001 C N Si Ta O H 0.0043 0.005 <0.005 0.006 0.005 <0.001

[0054] Step 2, carry out double-layer sieving of sponge zirconium, wherein the size of the upper sieve is φ12.4mm, and the size of the lower sieve is φ6mm, to obtain particles with a particle size of 3mm to 12.4mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com