Thermal insulation plate based on MOCVD equipment heater

A heater and heat insulation board technology, applied in metal material coating process, coating, gaseous chemical plating and other directions, can solve the problem of inability to meet the temperature adjustment of the graphite plate, and achieves reduced intervention, simple and fast replacement, and reduced size The effect of caliber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the invention, but not to limit the invention.

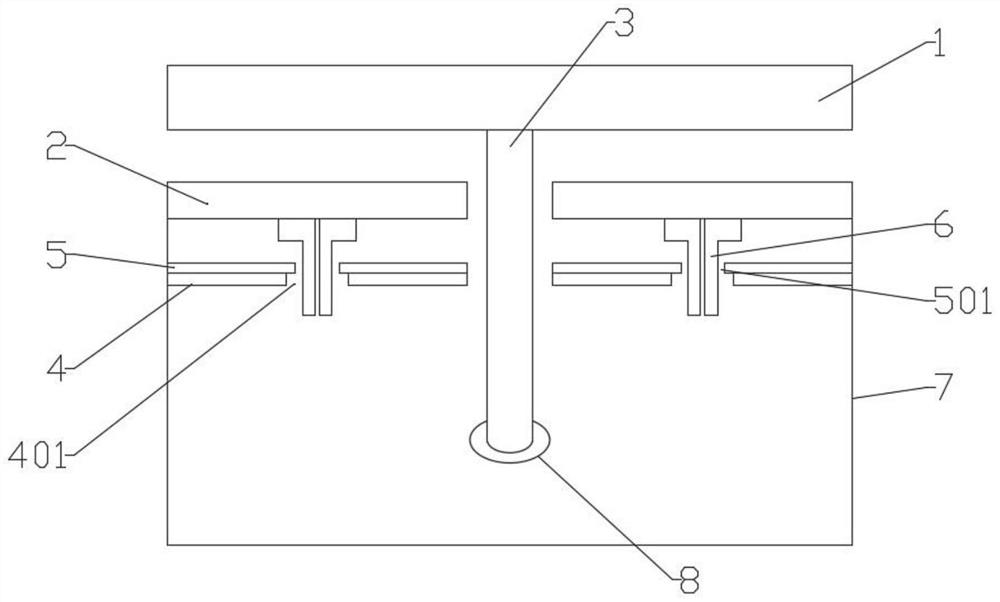

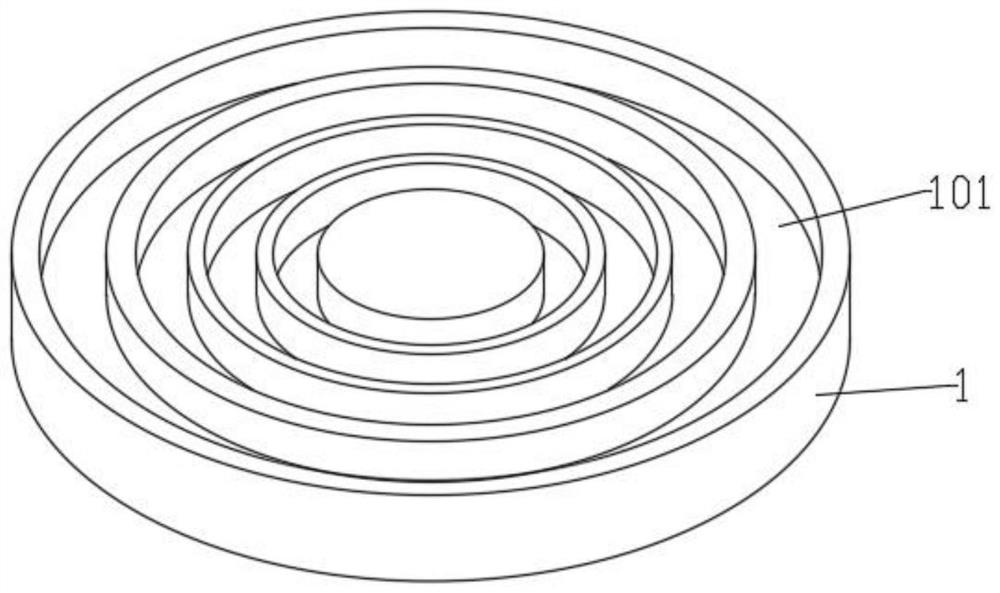

[0031] like Figure 1-5 As shown, the invention is a heat shield based on a MOCVD equipment heater, comprising: a carrier disc 1, a heater 2 arranged on the lower side of the carrier disc 1, and an insulating layer 4 arranged on the bottom of the heater 2, It is characterized in that, a heat shield mechanism is provided between the bottom of the heater 2 and the heat insulating layer 4;

[0032] A heater electrode 6 is provided at the bottom of the heater 2, and the heater electrode 6 passes through the heat insulating layer 4 and the heat insulating plate mechanism;

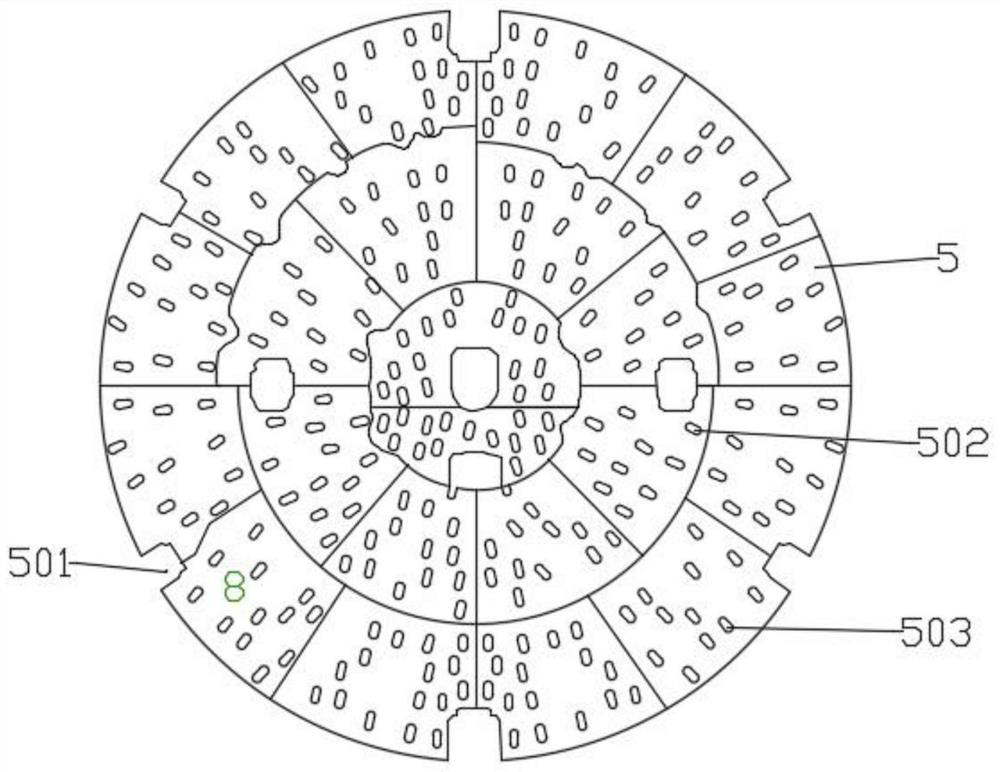

[0033] The heat insulation board mechanism is composed of a plurality of heat insulation boards 5 of different shapes assembled.

[0034] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com