Automatic additive feeding device and washing machine

An automatic feeding and additive technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of inconvenient cleaning of the liquid storage box, too much or too little additives, and fading of clothes. Feature-rich, powerful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

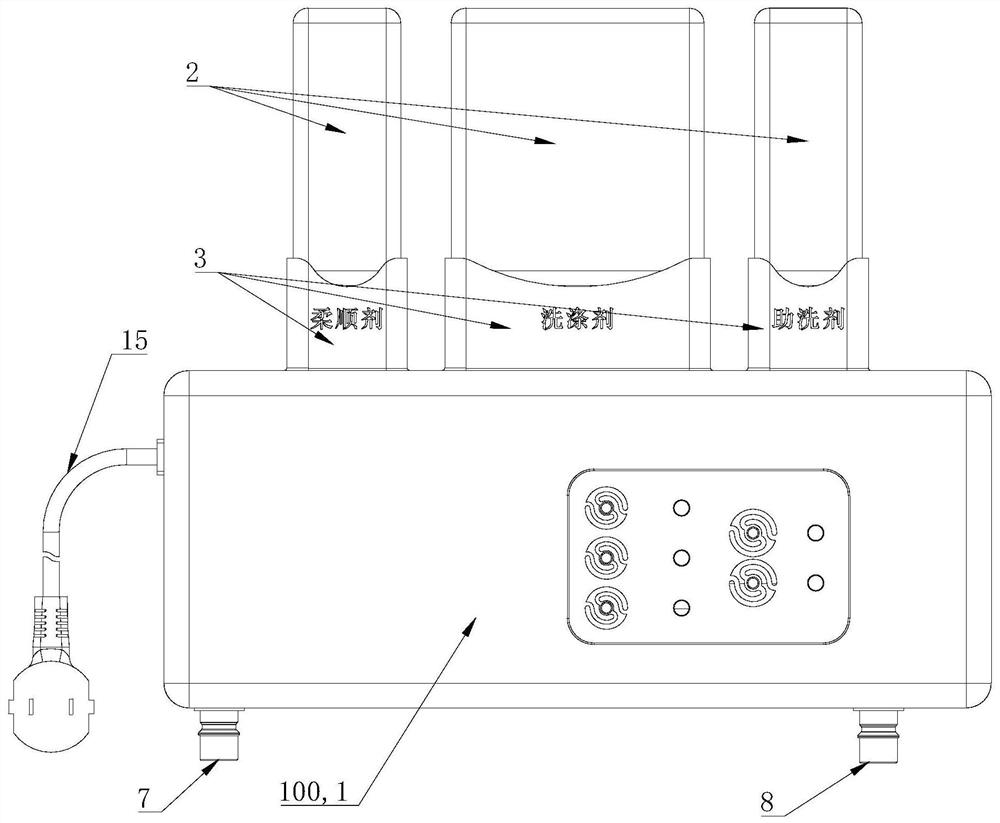

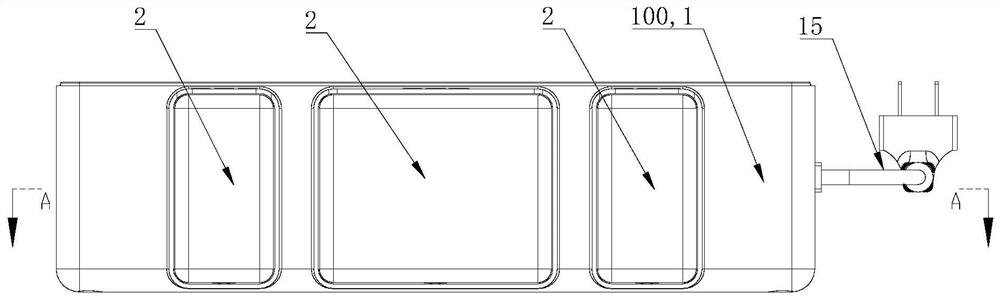

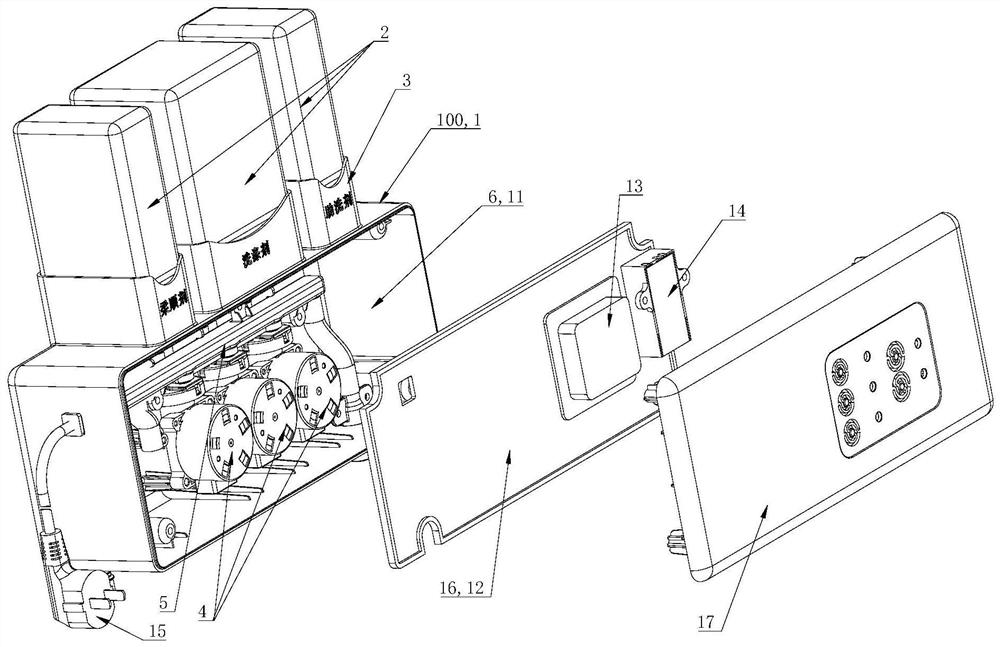

[0045] To make the purposes, technical solutions, and advantages of the embodiments of the present invention clearer, the following will describe the defect management mode in the embodiments in detail with reference to the accompanying drawings in the embodiments of the present invention.

[0046] like Figure 1 to Figure 8As shown, an additive injection device is introduced in this embodiment, and the injection device 100 includes: a casing 1 composed of independent components. The outer wall of the casing 1 is provided with at least one insertion slot 3 , and the opening of each insertion slot 3 constitutes a pull-out opening disposed toward the outside of the casing 1 . A liquid storage box 2 that is adapted and can be pulled out from the pull-out opening and pushed inward is installed in each socket slot 3, respectively. The liquid storage box 2 constitutes a sealed cavity for additive storage; The liquid cartridge 2 is an ink cartridge type sealed container, which direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com