Hole shaft offset detection jig and operation method thereof

A technology for detecting jig and offset, applied in the field of parts detection, can solve the problems of chip damage, inaccurate measured offset, inability to accurately measure positioning holes and positioning shafts, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to describe in detail the technical content, structural features, and achieved effects of the present invention, detailed descriptions are given below with reference to the embodiments and the accompanying drawings.

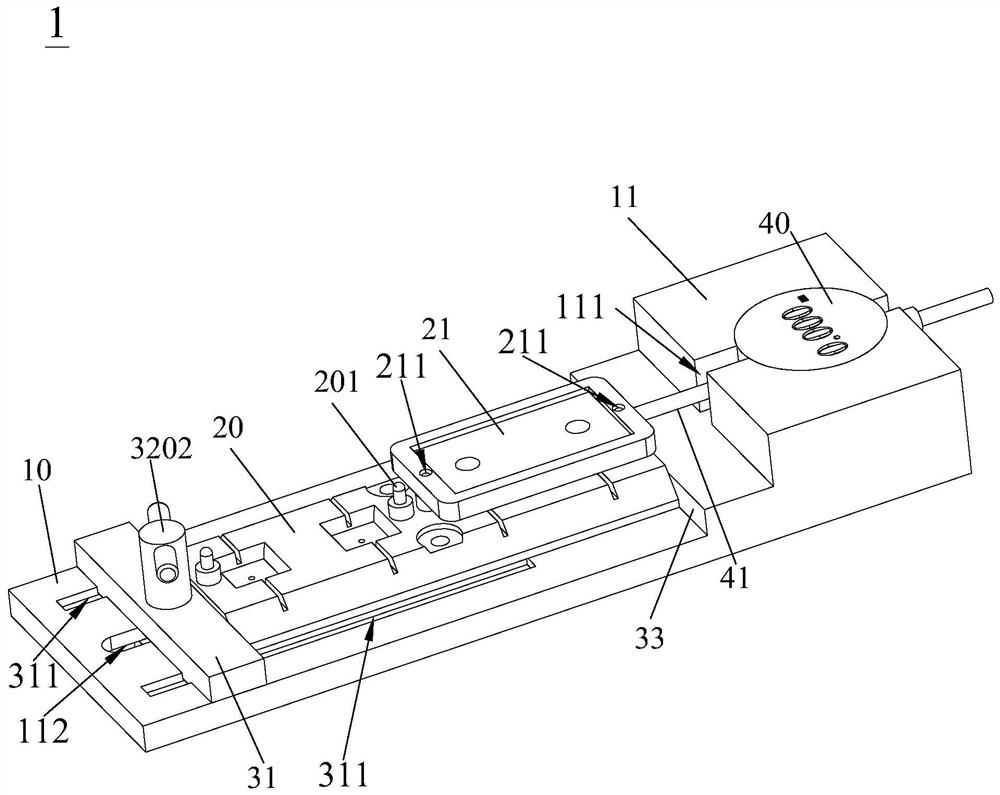

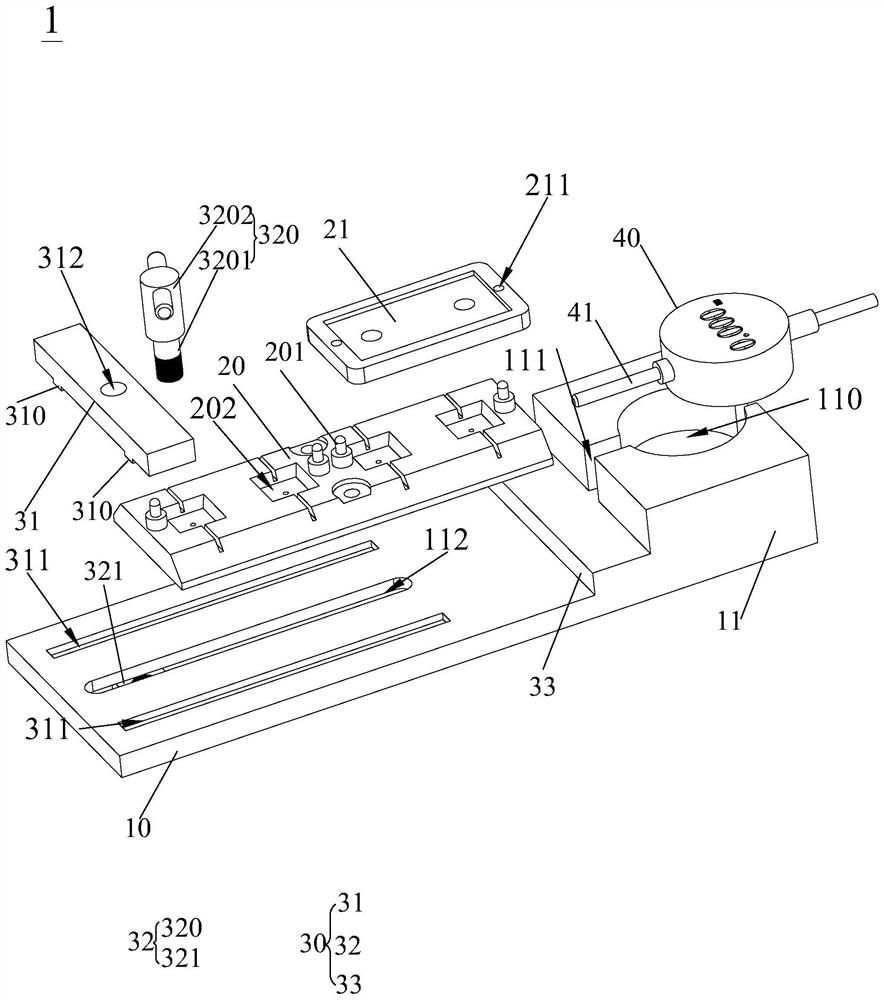

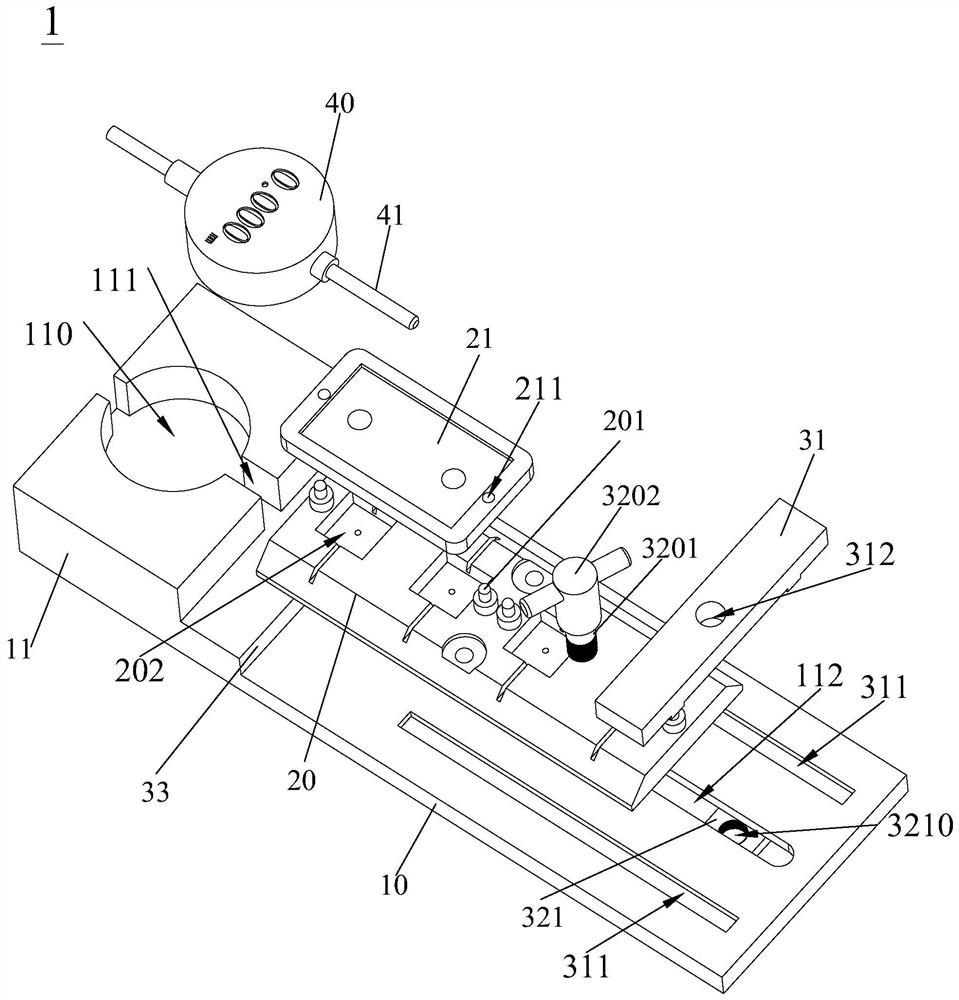

[0032] see Figure 1 to Figure 5 , the embodiment of the present invention discloses a hole axis offset detection fixture 1 , which includes a base 10 , a first substrate 20 , a second substrate 21 , a fixing device 30 and a detection device 40 .

[0033] The first substrate 20 is provided with one of the positioning shaft 201 and the positioning hole 211 , the second substrate 21 is provided with the other one of the positioning shaft 201 and the positioning hole 211 , and the second substrate 21 is assembled on the first substrate 20 When the positioning shaft 201 is inserted into the positioning hole 211 , the fixing device 30 is used to fix the first substrate 20 on the base 10 , and the detection device 40 is used to detect that the second su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com