Double-pressing straw cup cover

A straw and cup cover technology, applied in the field of cups, can solve the problems of affecting the service life, unsightly appearance, inconvenient use, etc., and achieve the effects of improving the service life, facilitating normal drinking, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with specific embodiment, the present invention is further described:

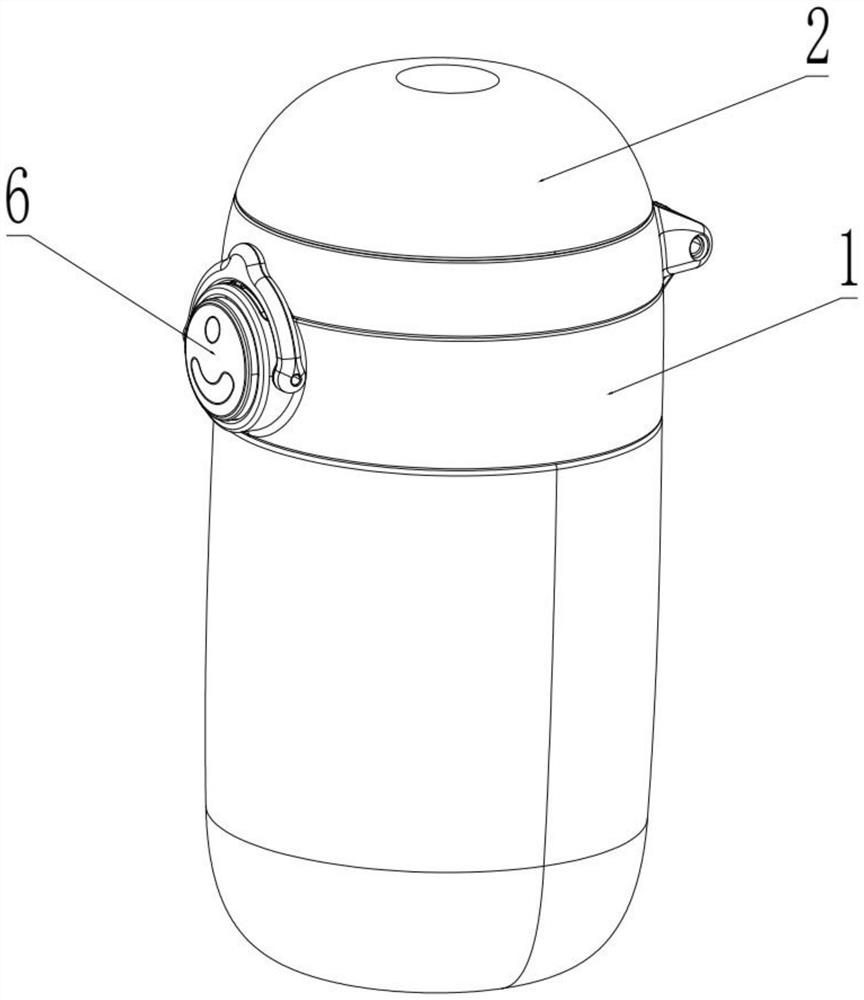

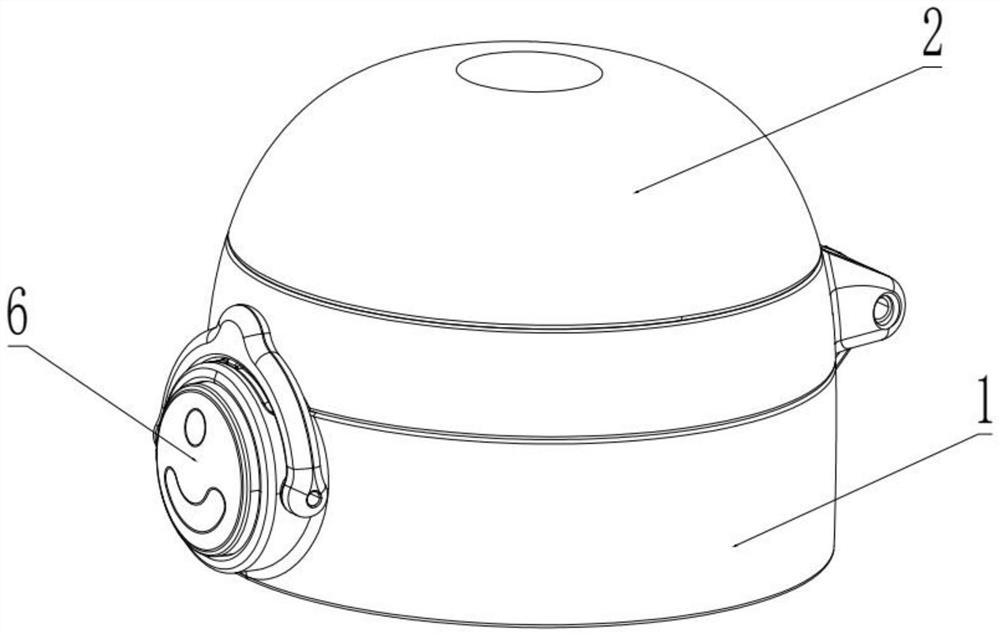

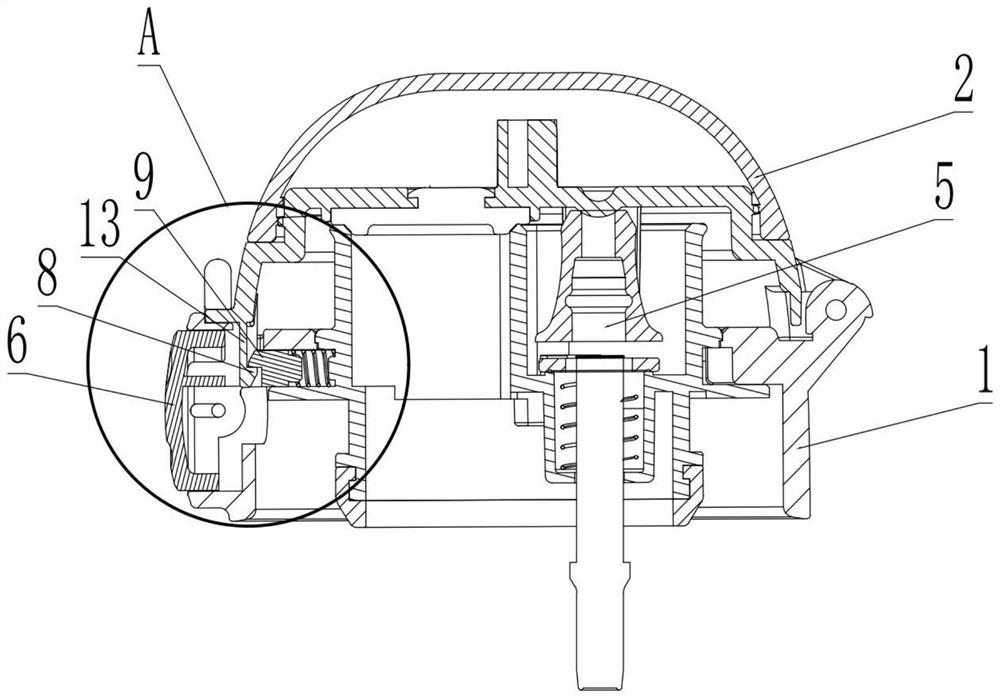

[0046]A double-pressed straw cup lid includes a lid body 1, a flip cover 2 is hinged on the back side of the lid body 1, a straight drinking channel 3 and a straw channel 4 that penetrate up and down are formed on the lid body 1, and the straw channel 4 is provided with up and down The movable straw assembly 5; the front side of the cover body 1 is provided with a cover opening button 6, the inner side of the cover opening button 6 is abutted with a transmission member 7, and the flip cover 2 is formed with a first snap portion 8, the transmission A first locking portion 9 is formed on the component 7. When the flip cover 2 is closed, the first locking portion 9 hooks the first snap portion 8; the straw assembly 5 is formed with a second snap portion 10. , a second locking portion 11 is formed on the transmission member 7. When the suction pipe assembly 5 is pressed down, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com