Automatic clamp tool assembly for steering knuckle master pin machining

A steering knuckle, automatic technology, applied in metal processing machinery parts, manufacturing tools, clamping devices, etc., can solve the problems of poor operability, low automation level, and difficult to guarantee stability, and achieve reasonable structure, ensure accurate implementation, The effect of improving the fixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

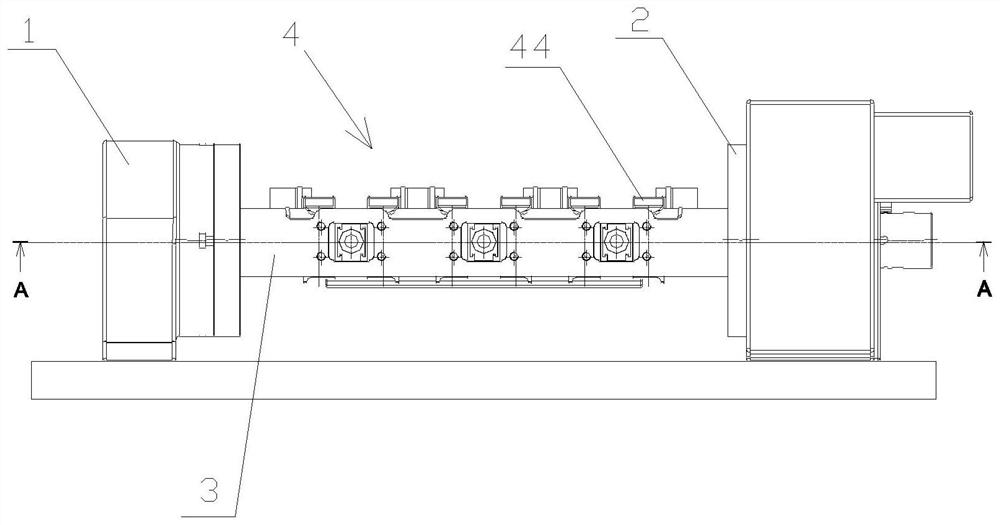

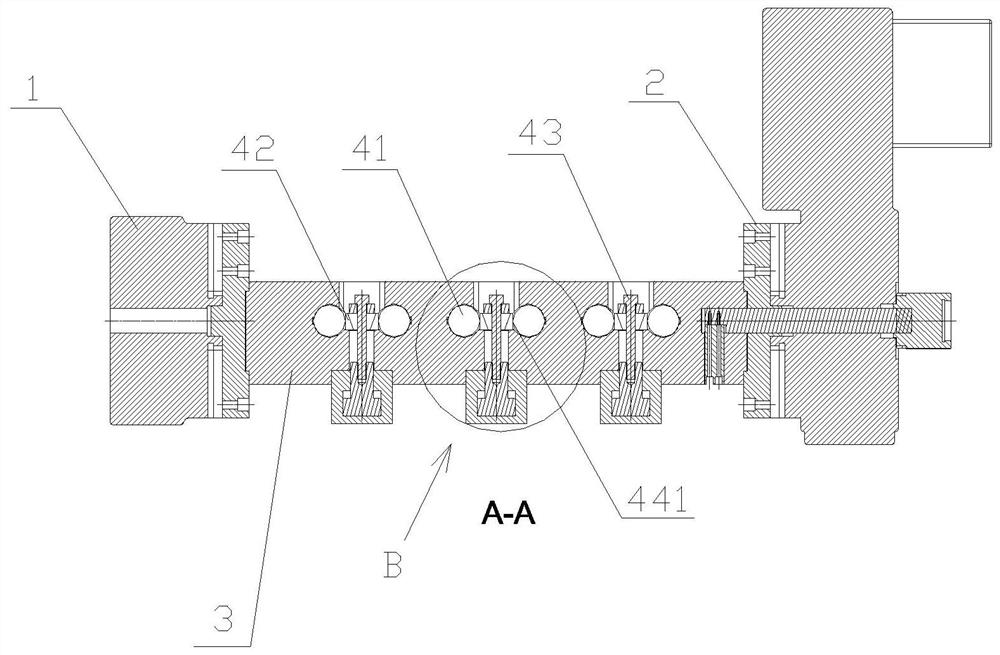

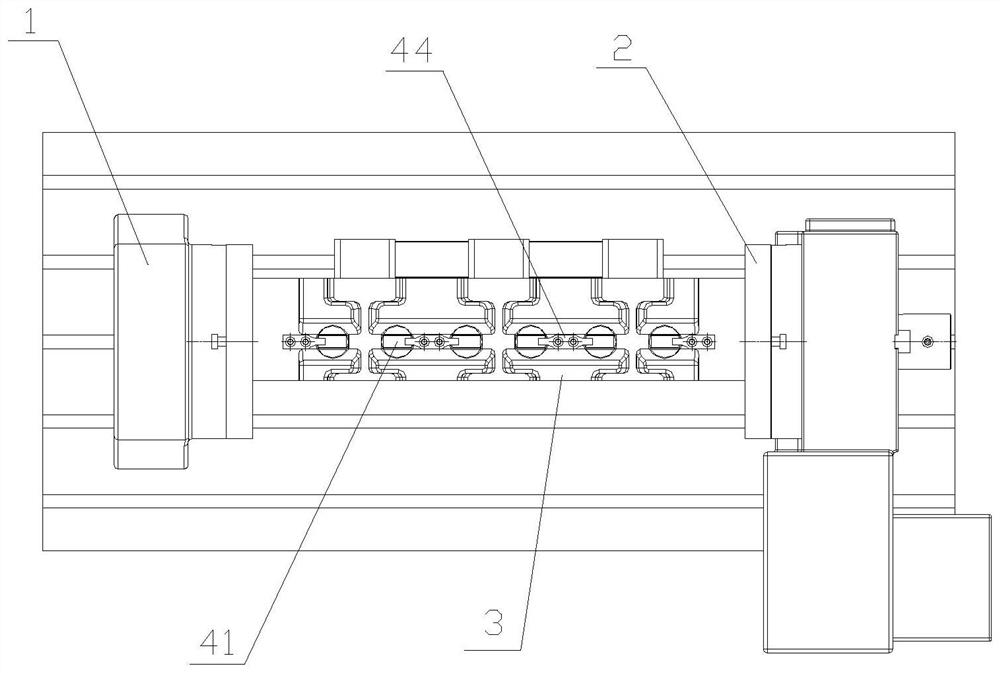

[0024] like Figure 1 to Figure 4 As shown, an automatic fixture tooling assembly for processing a steering knuckle kingpin includes a processing table 1, a mounting seat 2 fixedly installed on both sides of the upper part of the processing table 1, and a rotating automatic fixture installed in the middle of the two mounting seats 2, the said The rotating automatic fixture includes a rotating body 3, and more than two sets of kingpin fixing parts 4, the kingpin fixing parts 4 are fixedly mounted on the rotating body 3, and the rotating body 3 drives the kingpin fixing part 4 to rotate; The kingpin fixing member 4 includes: a kingpin placing fixing slot 41, an automatic locking block 42, a locking rod 43, and a driving device 44. The kingpin placing fixing slot 41 is provided with a fixing opening 411, and the automatic locking The block 42 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com