Novel package forming machine

A molding machine and wrapping technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complicated production process, slow production speed, inability to meet the working conditions of small and medium-sized products, and achieve high-precision control of the pressing plane. degree and pressing force, no human factor error, and the effect of a wide range of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" ” refer to directions towards or away from the geometric center of a particular part, respectively.

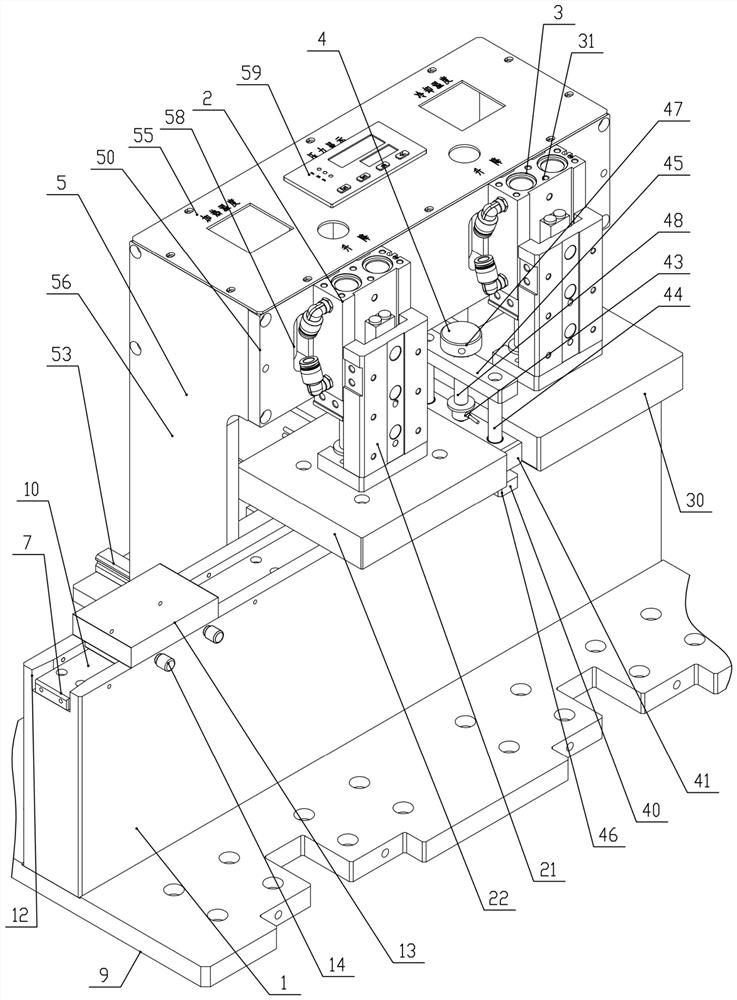

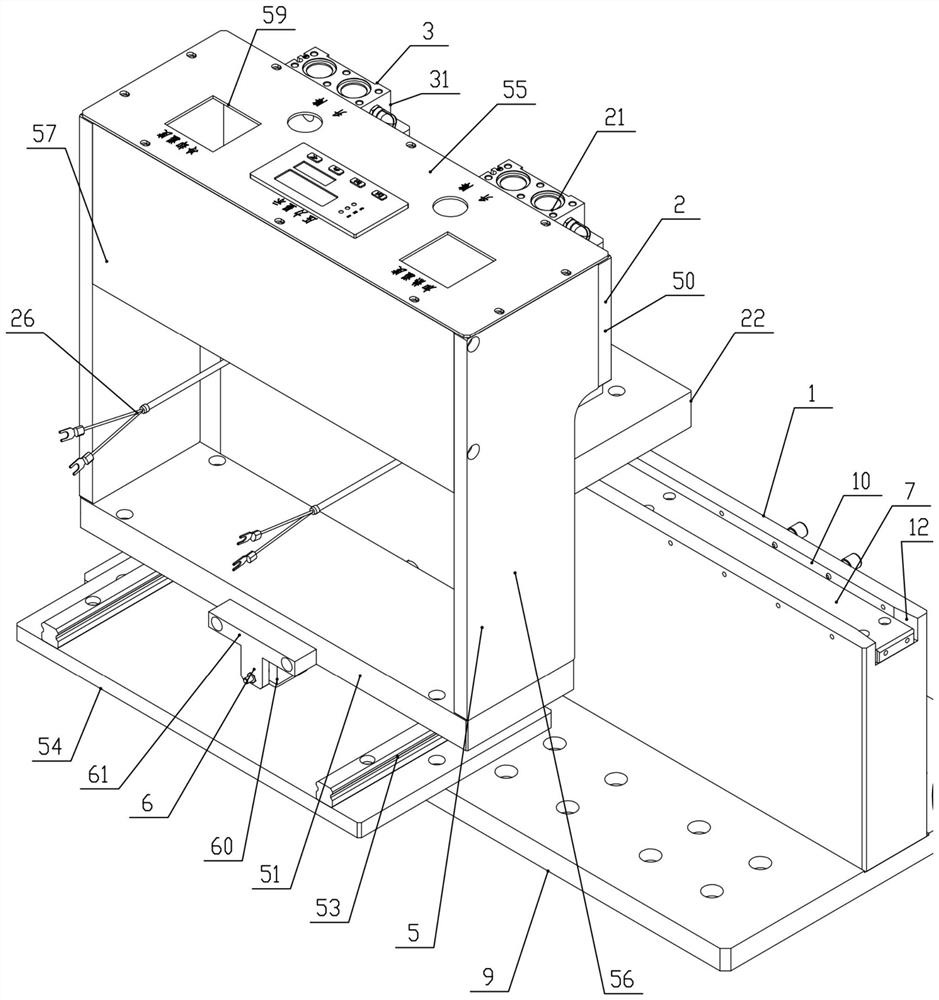

[0038] Figure 1 to Figure 8 A novel wrap forming machine according to one embodiment of the present invention is shown schematically. As shown in the figure, the device includes a feeding base 1, a hot pressing module 2, a cooling module 3, a pressure control part 4, a moving gantry 5 and a safety adjustment part 6;

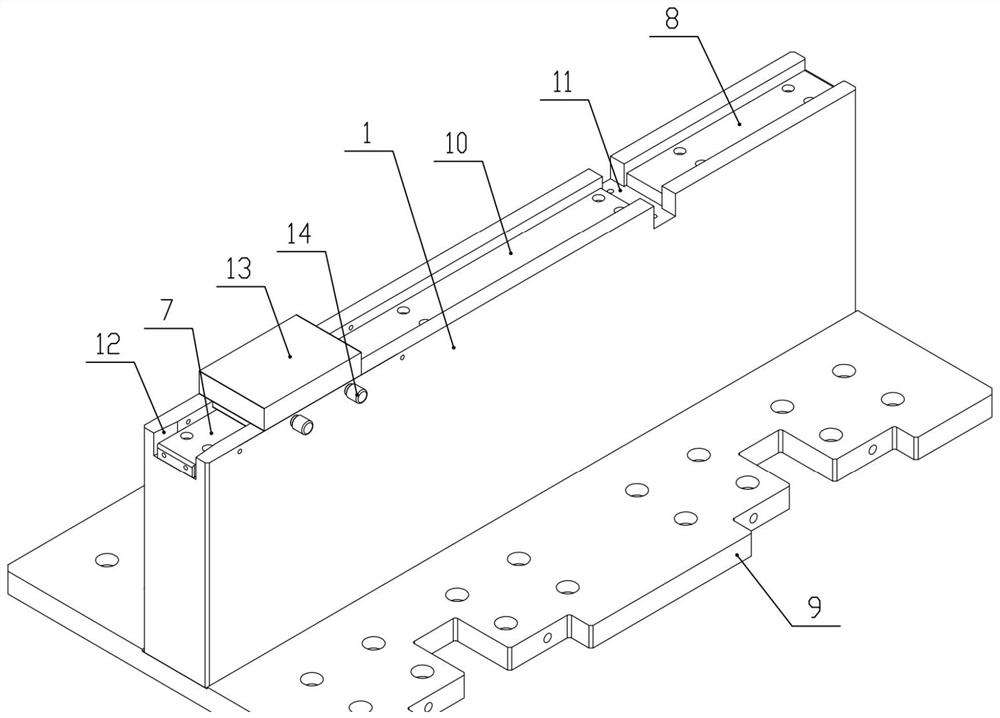

[0039] The feeding base 1 is vertically connected to the middle of the flat base plate 9. The upper surface of the feeding base 1 is formed with vertically staggered transverse guide grooves 10 and longitudinal pressure grooves 11. On both sides of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com