Ultra-deep raft reinforcing steel bar support

A technology of steel support and deep raft, which is applied in the direction of building, building reinforcements, building components, etc., can solve the problem of not being able to cope with different ground support requirements, single and other problems, and achieve good overall use effect, stable support structure, and increased use. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

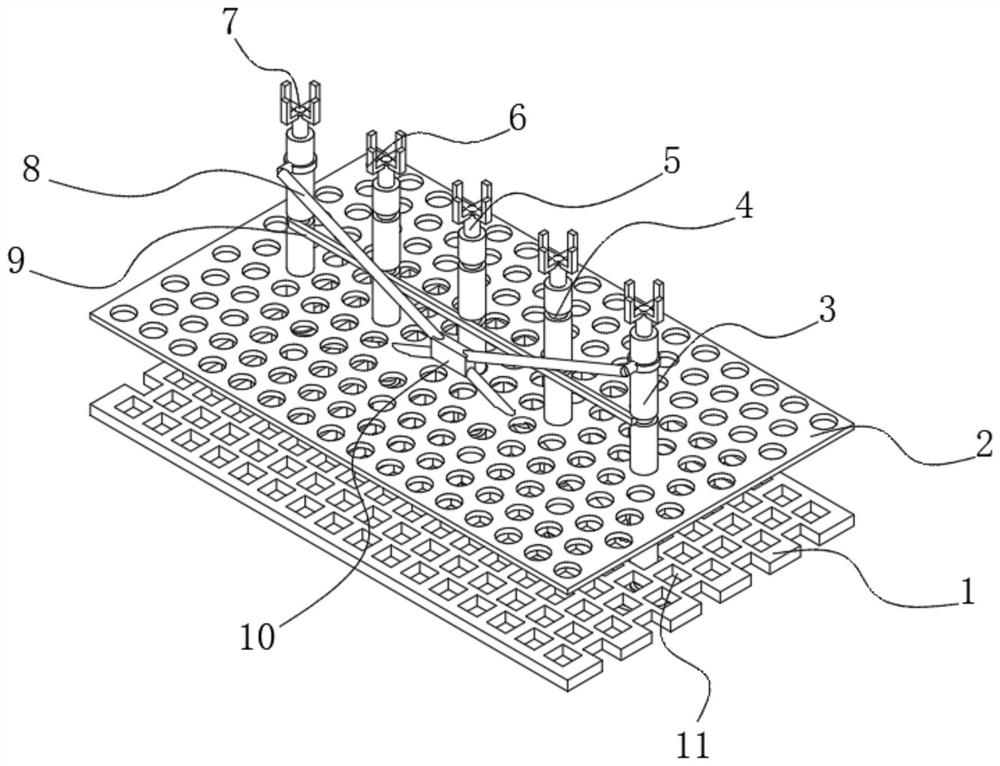

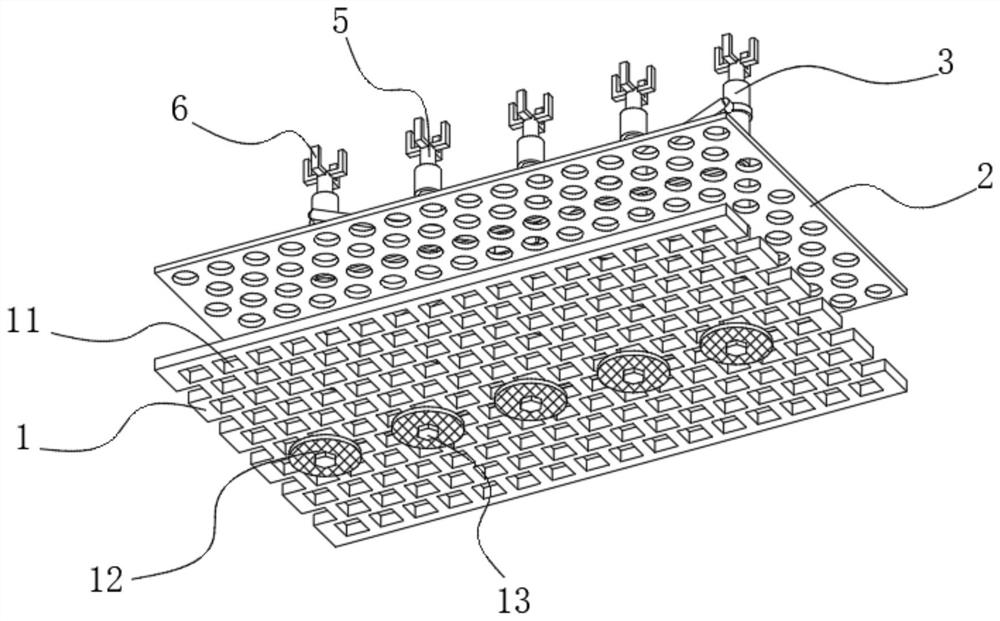

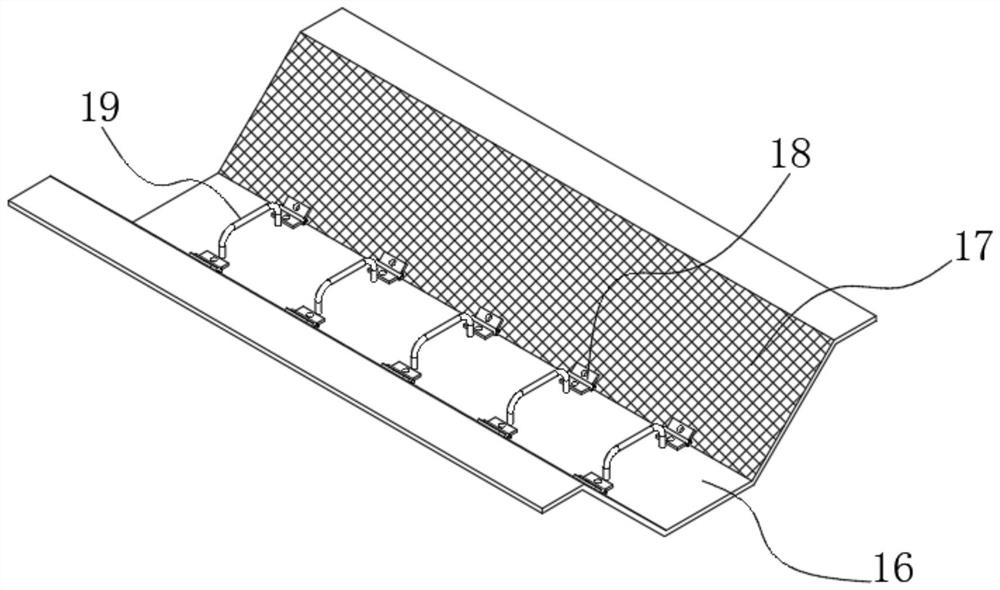

[0038] like Figure 1-Figure 6 As shown, an ultra-deep raft steel bar support includes a frame plate 1, a support bottom 15 and a bottom mesh plate 16. The interior of the frame plate 1 is provided with a rectangular groove 11, and the interior of the frame plate 1 is provided with a number of struts 3. The bottom of the rod 3 is movably installed with a reinforced mesh panel 12, the interior of the reinforced mesh panel 12 is inserted with a fixing bolt 13, the interior of the support rod 3 is provided with a number of ring grooves 4, and the inner ring groove 4 is movably installed with a ferrule 14, the sleeve. The outer side of the hoop 14 is movably installed with a reinforcement rod 8, the outer side of the reinforcement rod 8 is provided with a connecting piece 10, the inner side of the ring groove 4 is movably installed with a cross bar 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com