Modular optical cable cross-connecting box and assembling method

An optical cable junction box, modular technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., to achieve the effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the specific embodiments, structures, features and effects of the present invention are described in detail below in conjunction with the accompanying drawings and preferred embodiments.

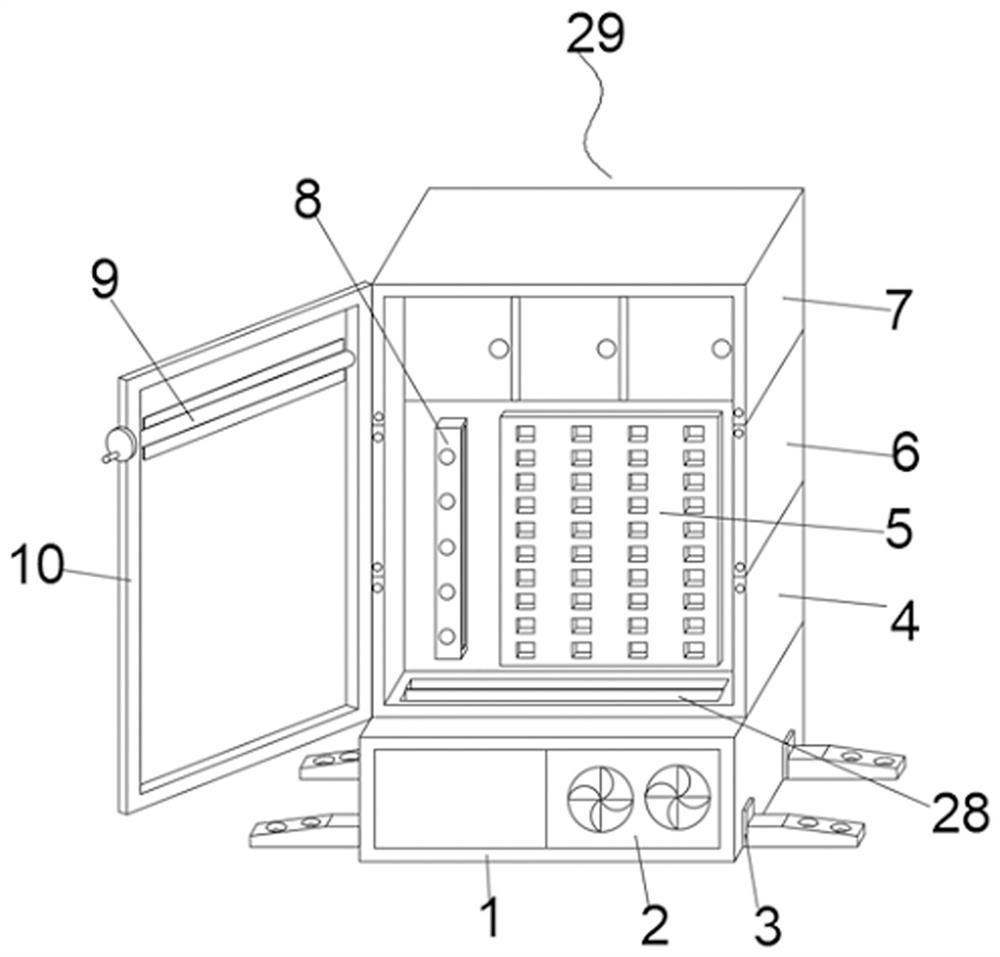

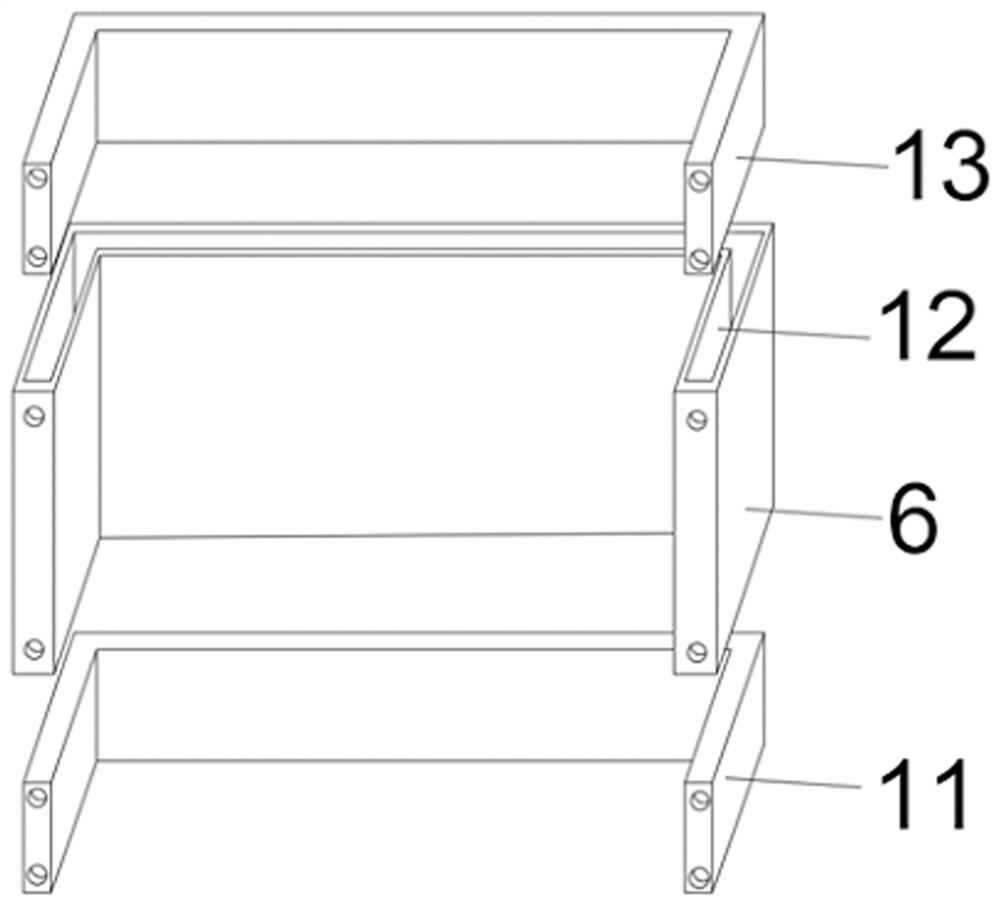

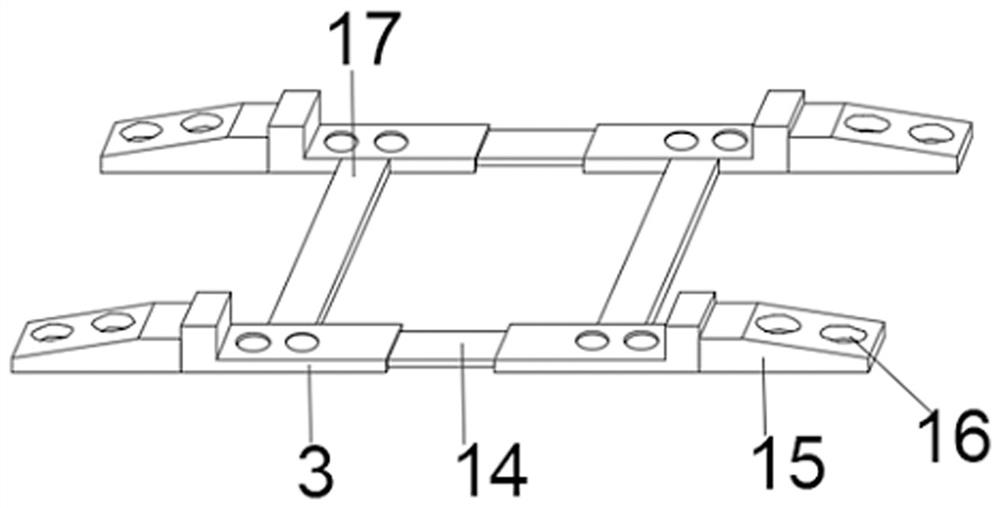

[0033] like Figure 1-5 As shown, a modular optical cable connection box includes a fixed base 1 and a box body assembly 29, the box body assembly 29 is fixedly installed on the outer surface of the upper end of the fixed base 1, and the front end of the box body assembly 29 is movably installed with a sealing door 10 , the box assembly 29 includes a splicing bottom plate 4, a splicing middle plate 6 and a splicing top plate 7, the splicing top plate 7 is spliced and installed on the upper end outer surface of the splicing middle plate 6, and the splicing bottom plate 4 is spliced and installed on the lower end outer surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com