Transmission tower main material bearing capacity calculation method considering bolt connection

A technology of transmission tower and calculation method, which is applied in the field of transmission tower to achieve the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

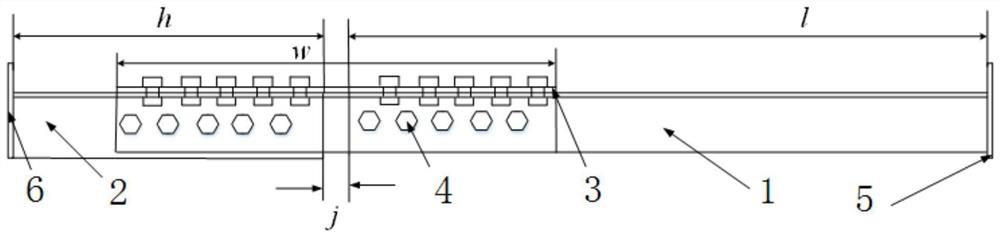

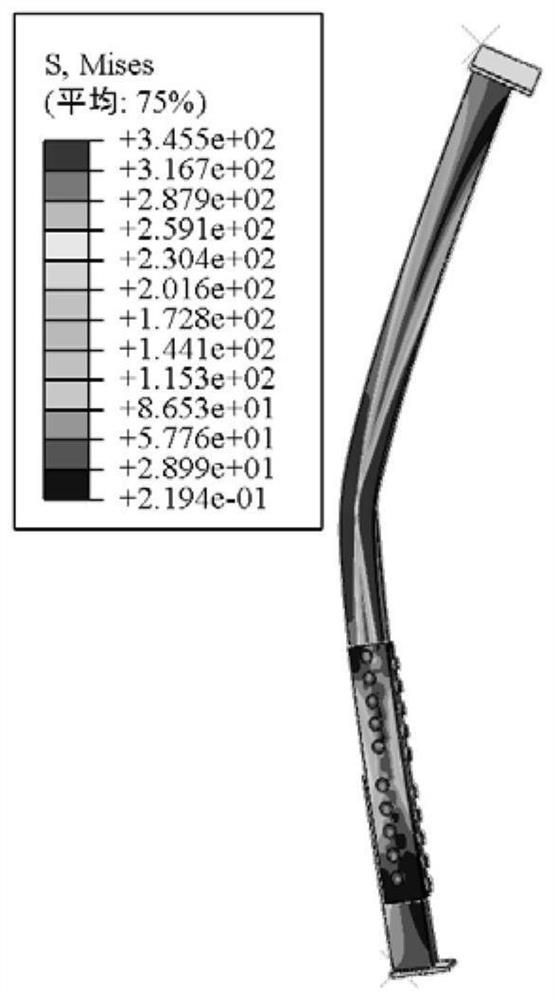

[0052] Firstly, taking the components at the damaged position of a 220kV ZMC2 transmission tower as the research object, the CREO software is used to establish a three-dimensional solid model of the main material of the transmission tower with bolted connections. As shown in Appendix 1, the main material model of the transmission tower with bolted connection consists of main material 1, main material 2, outer steel, end plate 1, end plate 2 and bolts. The bolt preload is 60% of the ultimate bearing capacity of the bolt. The non-linear buckling analysis of the member is carried out to obtain the bearing capacity of the member. And the influence law of parameters such as slenderness ratio, bolt size, bolt pre-tightening force, number of loose bolts and main material assembly clearance on the ultimate bearing capacity of components is analyzed.

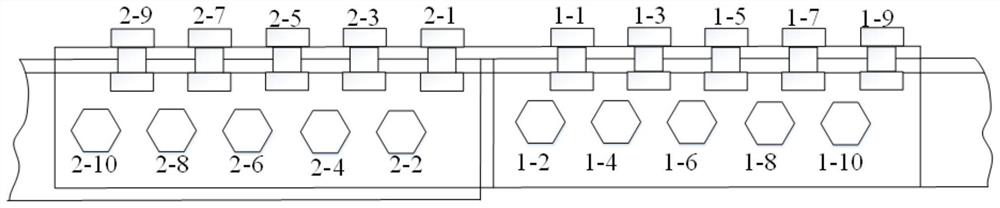

[0053] In order to analyze the influence of parameters such as slenderness ratio, bolt size, bolt pre-tightening force, number of loos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com