Generative design method for special-shaped fuel structure of fast neutron reactor core

A fast neutron reactor and design method technology, applied in the field of nuclear power, can solve the problems of not being able to achieve the best heat transfer effect, heat transfer efficiency limited contact area and geometry, etc., to avoid the grid division process and reduce the risk of overheating , the effect of saving calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] In order to make the technical solution of the present invention clearer, the implementation of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

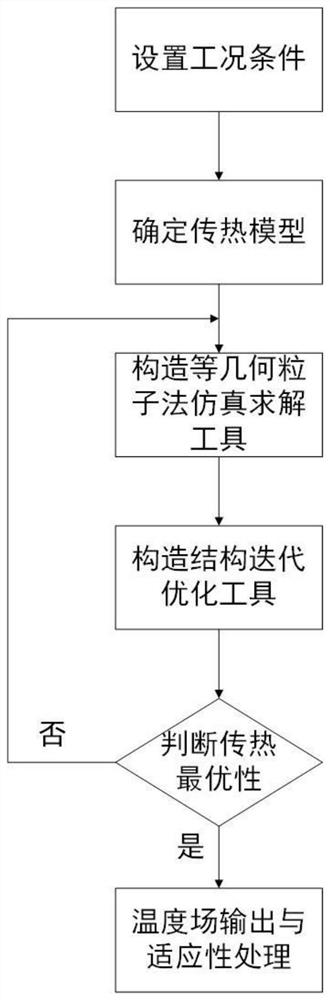

[0088] refer to figure 1 , a generative design method for a fast neutron core special-shaped fuel structure, comprising the following steps:

[0089] 1) Set working conditions:

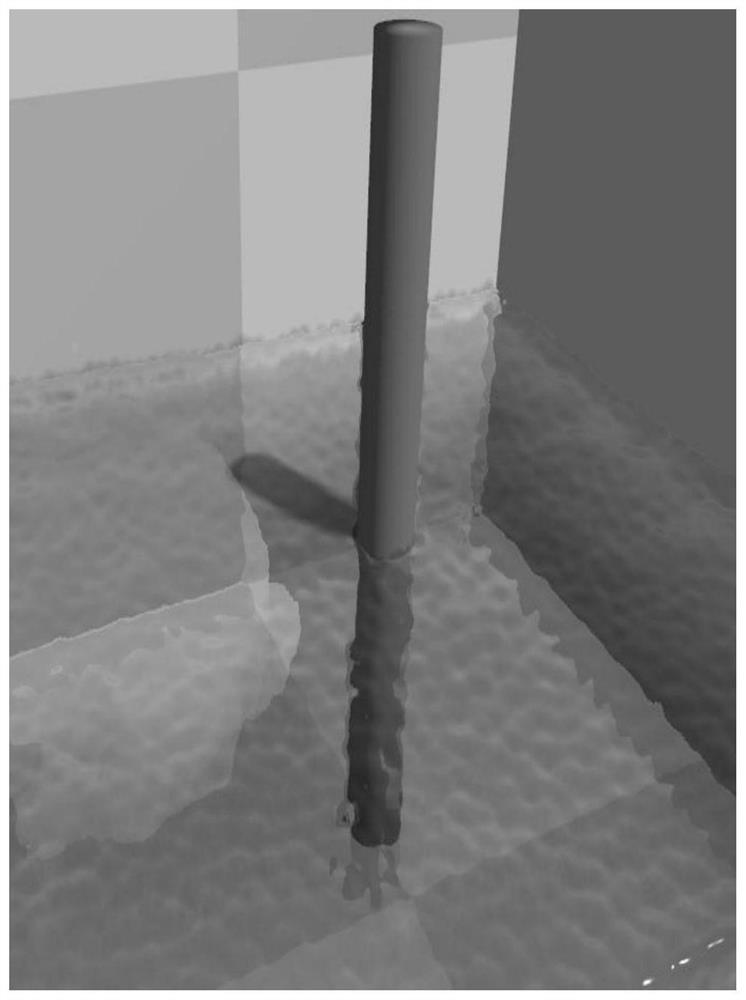

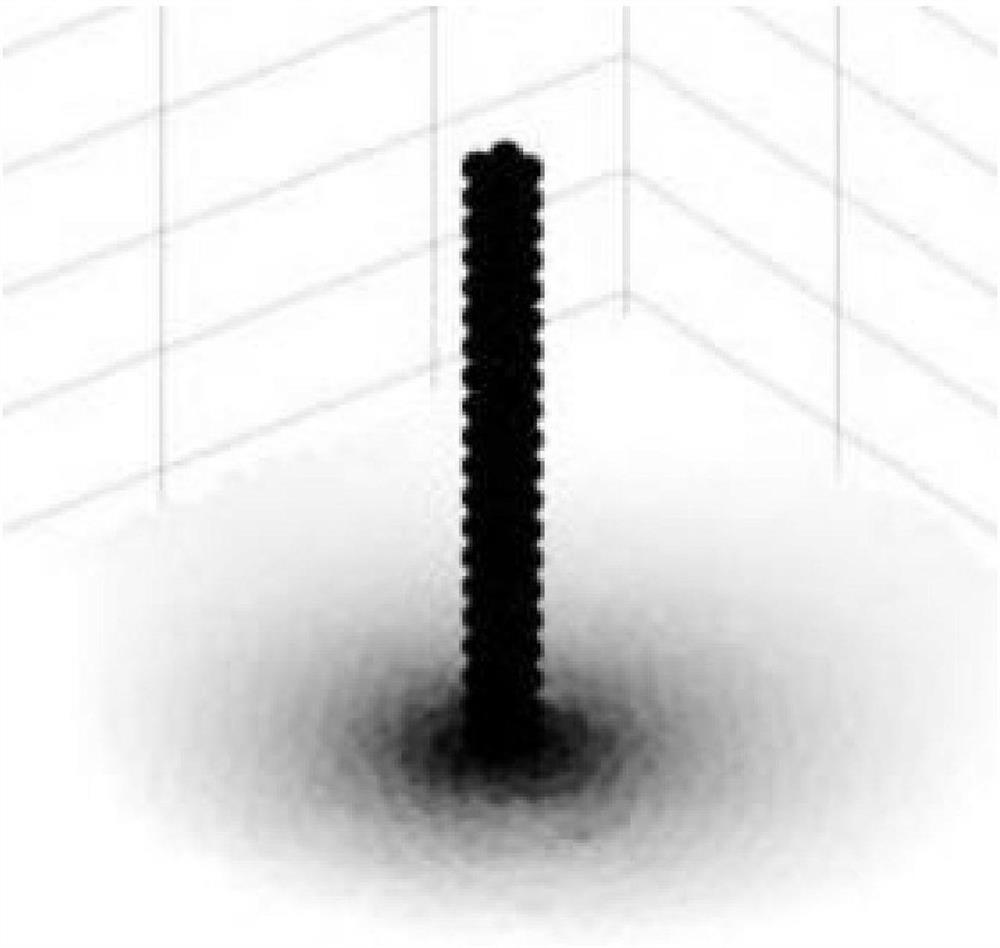

[0090] A certain type of core special-shaped fuel structure assumes a working condition, a cylinder with a length of 200 mm and a diameter of 20 mm is used as the design domain, the coolant is water, and the material of the core special-shaped fuel structure is simplified as a solid uranium dioxide ceramic pellet, The surrounding walls are thermally insulated, the center temperature of the special-shaped fuel structure of the core is constant at 500 degrees, and the initial temperature of the coolant is 20 degrees. The initial structure is as follows: figure 2 shown;

[0091] 2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com