Isolation switch and static contact assembly thereof

A technology for isolating switches and static contacts, which is applied in air switch parts, switches with movable electrical contacts, contact heating/cooling, etc., can solve the problems of prone to discharge at the end of static contacts, and achieve guidance And the heat dissipation effect is good, the effect of ensuring safe use and avoiding tip discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

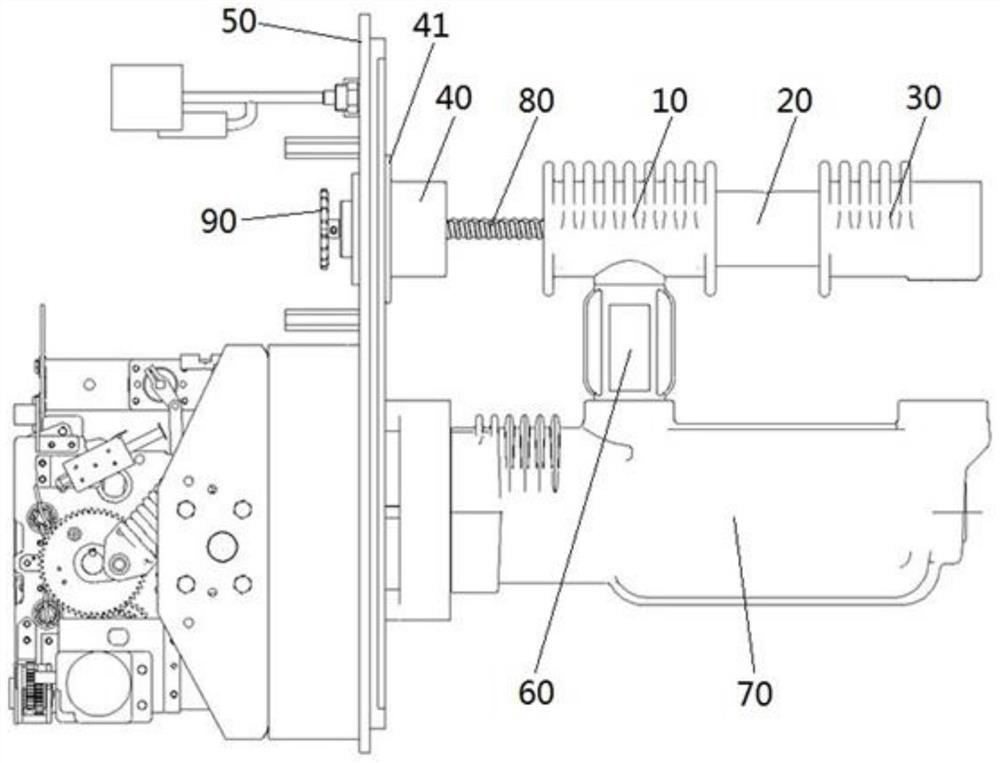

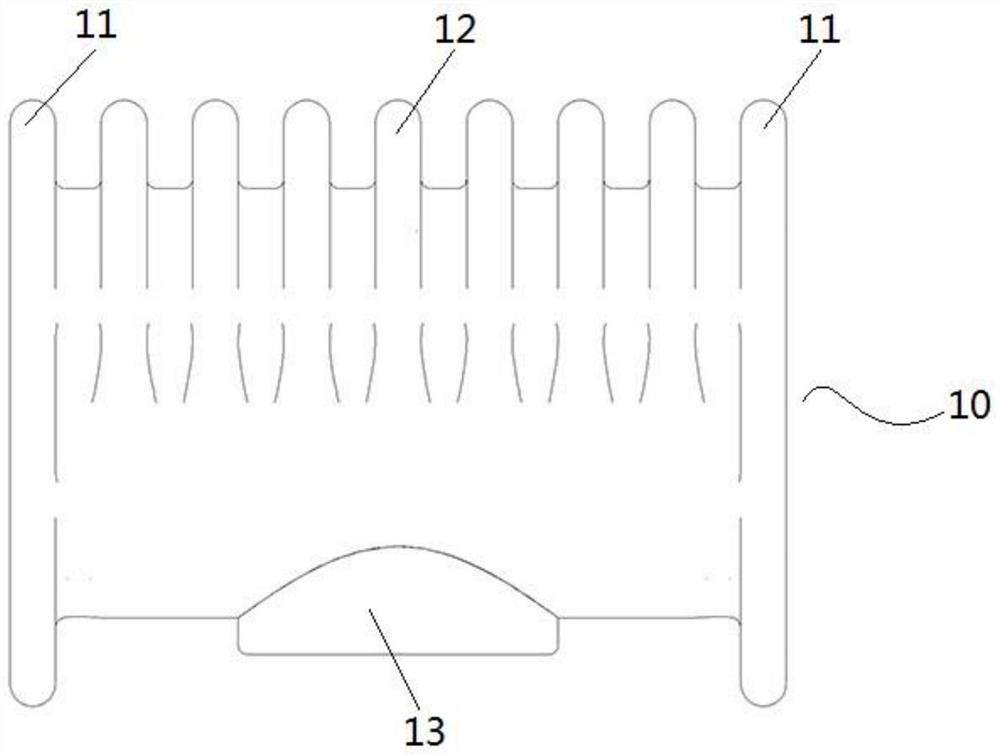

[0044] like figure 1 As shown, the isolating switch in this embodiment is a three-position isolating grounding switch, and the isolating switch includes a static contact and a moving contact 20 that is plugged into the static contact, wherein the static contact includes a middle static contact 10, and the middle static contact The contact 10 is provided with a first connection portion 13, and the first connection portion 13 is connected to the conductive seat 60 on the solid-sealed pole 70, wherein the solid-sealed pole 70 is fixed on the mounting plate 50 of the inflatable cabinet, and the first connection The portion 13 is connected to the conductive seat 60 , so that the intermediate static contact 10 is connected to the solid-sealed pole 70 through the connection of the first connection portion 13 to the conductive seat 60 .

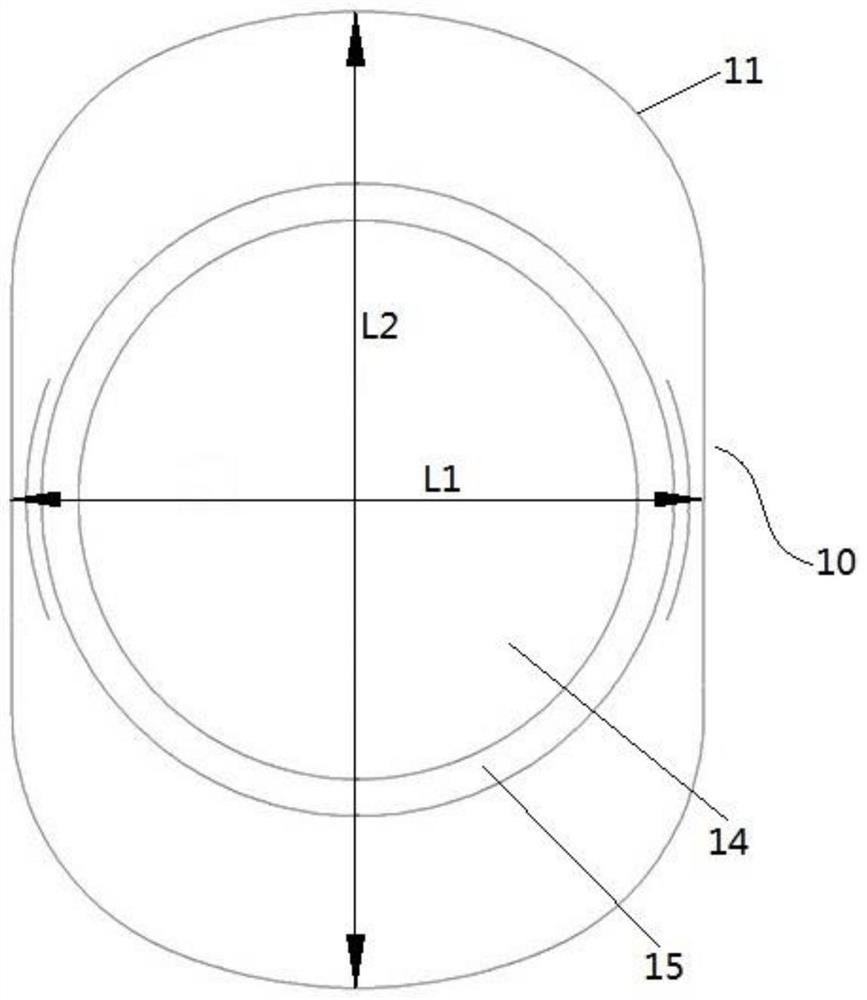

[0045] like image 3 As shown, the middle part of the intermediate static contact 10 is provided with a first axial through hole 14 extending along...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the movable contact through hole 21 includes an internal thread segment 22 for threading with the insulating lead screw 80 and a heat dissipation segment provided with a heat dissipation groove. However, in this embodiment, the movable contact through hole 21 only includes the internal thread segment 22 for threaded engagement with the insulating lead screw 80 . At this time, only a part of the movable contact through hole 21 may be the thread segment 22 , or all of the thread segment may be included. twenty two.

Embodiment 3

[0056]The difference between this embodiment and Embodiment 1 is that in Embodiment 1, the movable contact 20 is provided with a movable contact through hole 21 extending along its own axial direction, and the movable contact through hole 21 includes a contact hole 21 for connecting with the insulating lead screw 80 . The inner thread segment 22 , that is, the movable contact 20 , is driven to move by the insulating lead screw 80 . In the present embodiment, the movable contact 20 may not be provided with the movable contact through hole 21. In this case, a rack is provided outside the movable contact 20, and is equipped with a gear that cooperates with the rack to drive the movable contact through the rack and pinion structure. 20 reciprocating movements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com