Large-current contact element and flat connector

A contact and high-current technology, applied in the direction of contact parts, connections, electrical components, etc., can solve the problems of low space utilization rate of electrical contact area, increased use of materials, and large occupied area, so as to achieve small space applications and improve electrical conductivity The effect of simple cross-section and manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

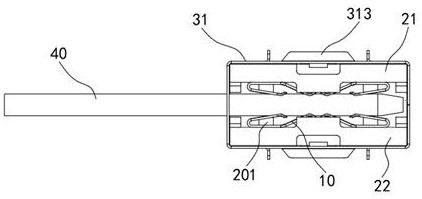

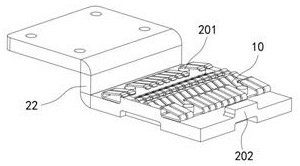

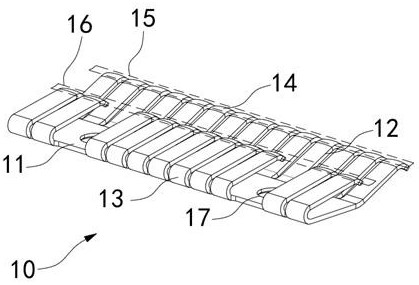

[0039] Please refer to Figure 1-4 , a large current contact piece 10 , comprising a rectangular sheet body 11 .

[0040] One side of the rectangular sheet body 11 is provided with a plurality of upturned elastic sheets 12, and the other side of the rectangular sheet body 11 is provided with a plurality of bending elastic sheets 13, and the upturning direction of the upturned elastic sheet 12 is the same as the bending direction of the bending elastic sheet 13. The plane defined by the end of the raised elastic piece 12 and the end of the bent elastic piece 13 is parallel to the rectangular sheet body 11 .

[0041] The ends of the plurality of upturned elastic sheets 12 form the first contact area 15, and the ends of the plurality of bent elastic sheets 13 form the second contact area 16. When the contact piece 10 is in contact with the external insert 40, the first contact area 15 and The second contact area 16 is in common contact with the external inserts 40, which increas...

Embodiment 2

[0061] Please refer to Figure 18 , this embodiment replaces the first plywood 21 and the second plywood 22 with a pair of third plywood 23 on the basis of the first embodiment, and the third plywood 23 is stepped (the height of the second plywood 22 is twice as high as that of the third plywood 23 height), a pair of third splints 23 are arranged opposite to each other, the same side of the pair of third splints 23 is fixedly connected, and the other side of the pair of third splints 23 is spaced with gaps, and multiple sets of positioning units are placed in a pair of On the opposite end surface of the other side of the third clamping plate 23 , the positioning columns 201 of each group of positioning units are clipped into the fixing holes 17 for fixing (please refer to the first embodiment). The other sides of the pair of third splints 23 are provided with card holes 203 , and both the first card 311 in the first transformation pattern and the fourth card 322 in the second ...

Embodiment 3

[0063] Please refer to Figure 19 and Figure 20 , this embodiment replaces the first plywood 21 and the second plywood 22 with the fourth plywood 24 and the fifth plywood 25 on the basis of the first embodiment, the fourth plywood 24 is a straight plate structure, and the two side walls of one end of the fourth plywood 24 There is a pressing piece 241, the fourth plywood 24 and two pieces of wire pressing piece 241 form a U-shaped structure, the fifth plywood 25 is stepped, and one end of the fifth plywood 25 is provided with a fixing bar 251, and the fixing bar 251 is inserted into the U-shaped structure It is fixedly connected with one end of the fourth plywood 24, the other end of the fourth plywood 24 and the other end of the fifth plywood 25 are spaced with a gap, and multiple sets of positioning units are respectively placed on the other end of the fourth plywood 24 and the other end of the fifth plywood 25 opposite. On the end surface of the locating unit, the locatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com