Welding gun flexible positioning device and method for robot

A flexible positioning and robot technology, applied in welding equipment, resistance welding equipment, manufacturing tools, etc., can solve the problems of flexible positioning and inconsistency, improve the utilization rate and utilization rate, and the positioning method is simple and operable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

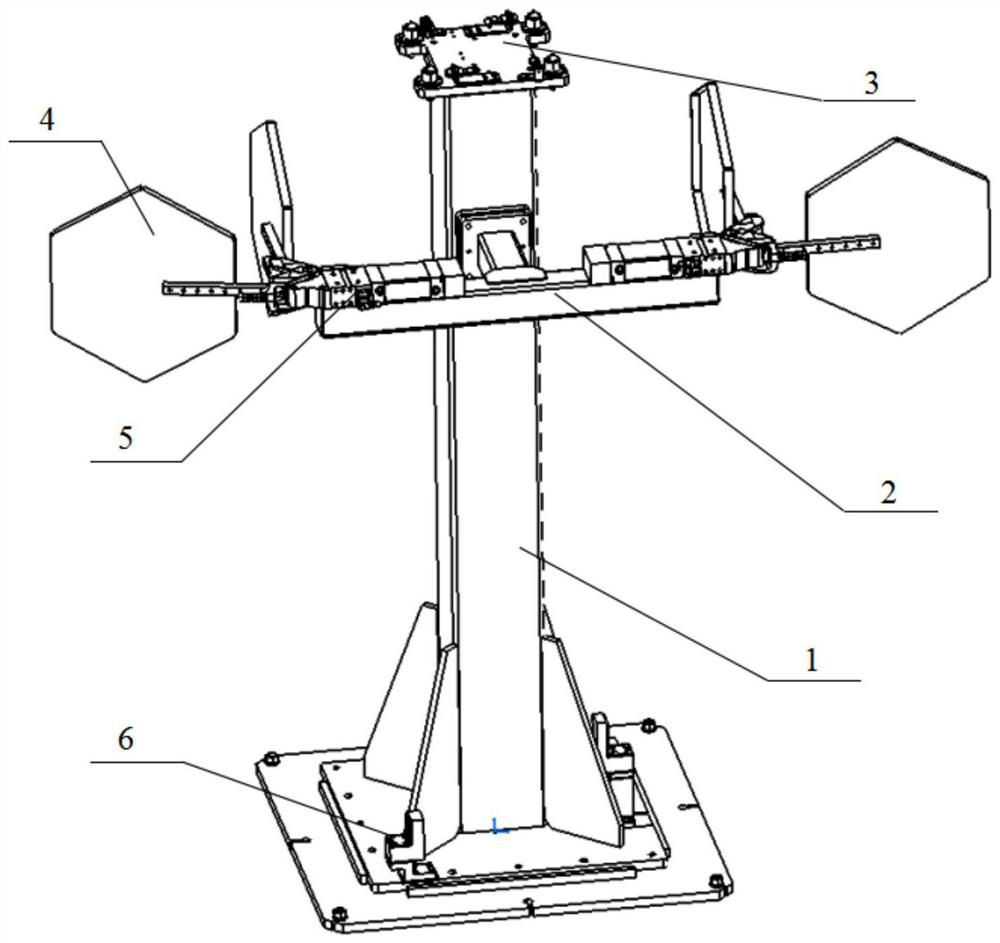

[0042] Refer to the attached Image 6 Shown: a flexible positioning method for a welding torch for a robot, which includes the following steps:

[0043] 1) Before the welding torch 7 works, on the welding torch positioning unit 3, the welding torch female head of the welding torch 7 is positioned and locked by the welding torch positioning pin 32, the welding torch support unit 6 supports the welding torch 7 to ensure balance, and the dust cover 4 is closed to protect welding torch 7;

[0044] 2) when the welding torch 7 is working, the robot drives the gun-changing disc male head of the welding torch 7 to move toward the robot with the welding torch flexible positioning device, and the rotary cylinder 5 rotates and drives the dust cover 4 to rotate, and the dust cover 4 is opened;

[0045] 3) The robot drives the male head of the torch changer of the welding gun 7 to insert it into the female head of the welding gun 7. The position sensor 34 detects that the male head of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com