Temperature control clamping device, crimping box and error code testing device

A technology of clamping device and temperature control module, which is applied in the field of digital communication, can solve the problems of module scratches, etc., and achieve the effects of not easy to scratch, effective crimping, and guaranteed crimping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

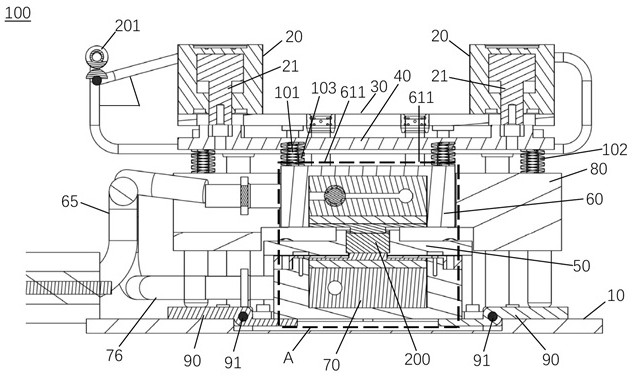

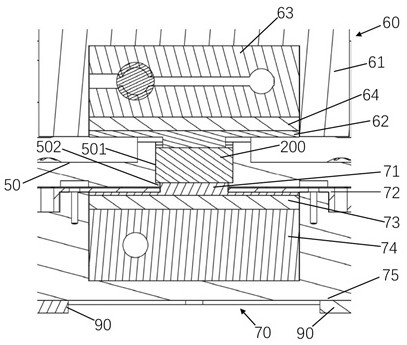

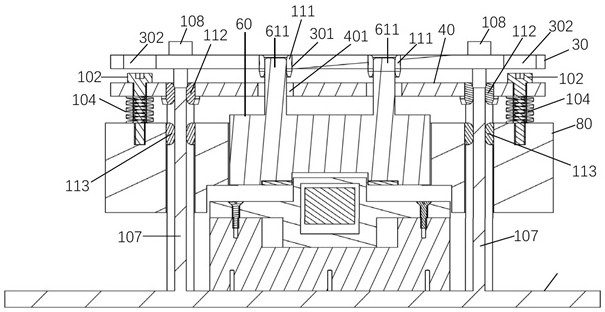

[0057] figure 1 A cross-sectional view of a temperature-controlled clamping device 100 (in a crimped state) according to one embodiment of the present invention. figure 2 Yes figure 1 Partial enlarged view at A. image 3 It is a structural cross-sectional view of the temperature-controlled clamping device 100 at the second fastener 102 according to an embodiment of the present invention. The present invention also provides a temperature-controlled clamping device 100 for crimping and temperature control of the optical module 200. In one embodiment, such as figure 1 As shown, the temperature control clamping device 100 includes a fixed base plate 10, a cylinder 20, a cylinder support plate 30, a movable push plate 40, a limit plate 50, an upper temperature control module 60, a lower temperature control module 70, a pressing block structure 80 and Lever plate 90. The cylinder 20 has a retractable plunger rod 21 . The cylinder support plate 30 is fixedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com