Paperboard cutting device for carton production

A cutting device and cardboard technology, applied in paper/cardboard containers, packaging, papermaking, etc., can solve the problems of inability to move cardboard, waste of cutting time, inaccessibility, etc., to avoid natural drying time and distribution of colloids Uniform, optimized cutting process results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

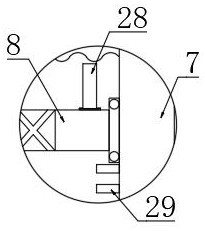

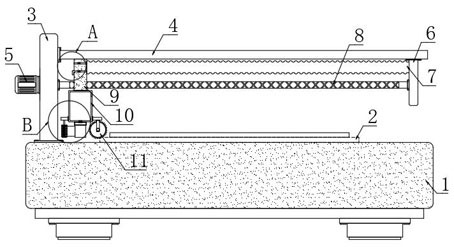

[0032] refer to Figure 1-5 , a cardboard cutting device for carton production, comprising a base 1, the upper end of the base 1 is installed with a limit component 2, the limit component 2 is the prior art, which can be in the patent document with the publication number "CN110252606B". The negative pressure suction structure composed of the ventilation hole and the vacuum generator is used to limit the position of the cardboard and facilitate subsequent cutting. The upper end of the base 1 is fixedly connected with a vertical plate 3, and the right side of the vertical plate 3 is fixedly connected with a Mounting plate 4, the lower end of the mounting plate 4 is fixedly connected with the airbag 7, the lower end of the vertical plate 3 is provided with a sliding block 9, the upper end surface of the sliding block 9 is slidably connected with the lower end surface of the mounting plate 4, the lower end of the mounting plate 4 is provided with useful As for the moving mechanism...

Embodiment 2

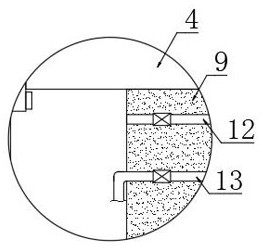

[0041] refer to Figure 6-9 The difference between this embodiment and Embodiment 1 is that the upper end of the connecting rod 15 penetrates the rectangular block 14. In this embodiment, the connecting rod 15 is slidably connected to the rectangular block 14, and the connecting rod 15 is provided with a movement plate 26 therethrough. , the movement plate 26 is fixedly connected with the connecting rod 15, the right side of the movement plate 26 is slidably connected with the left side wall of the glue storage box 10, the lower end of the movement plate 26 is elastically connected with the upper end of the rectangular block 14 through a plurality of springs 27, and the connecting rod The upper end of 15 is fixedly connected with an electromagnetic plate 25, and the inner top of the mounting plate 4 is embedded with a magnetic strip 24. After the electromagnetic plate 25 is energized, the adjacent surfaces of the magnetic strip 24 attract each other. The left side wall of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com