Deoxidation method of low-carbon wire drawing steel Q195LB

A wire drawing and deoxidizer technology, which is applied in the field of refining outside the steelmaking furnace, can solve the problems of increasing slag cost, incomplete oxide reduction, and lack of slag foaming ability, etc., and achieve reliable deoxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

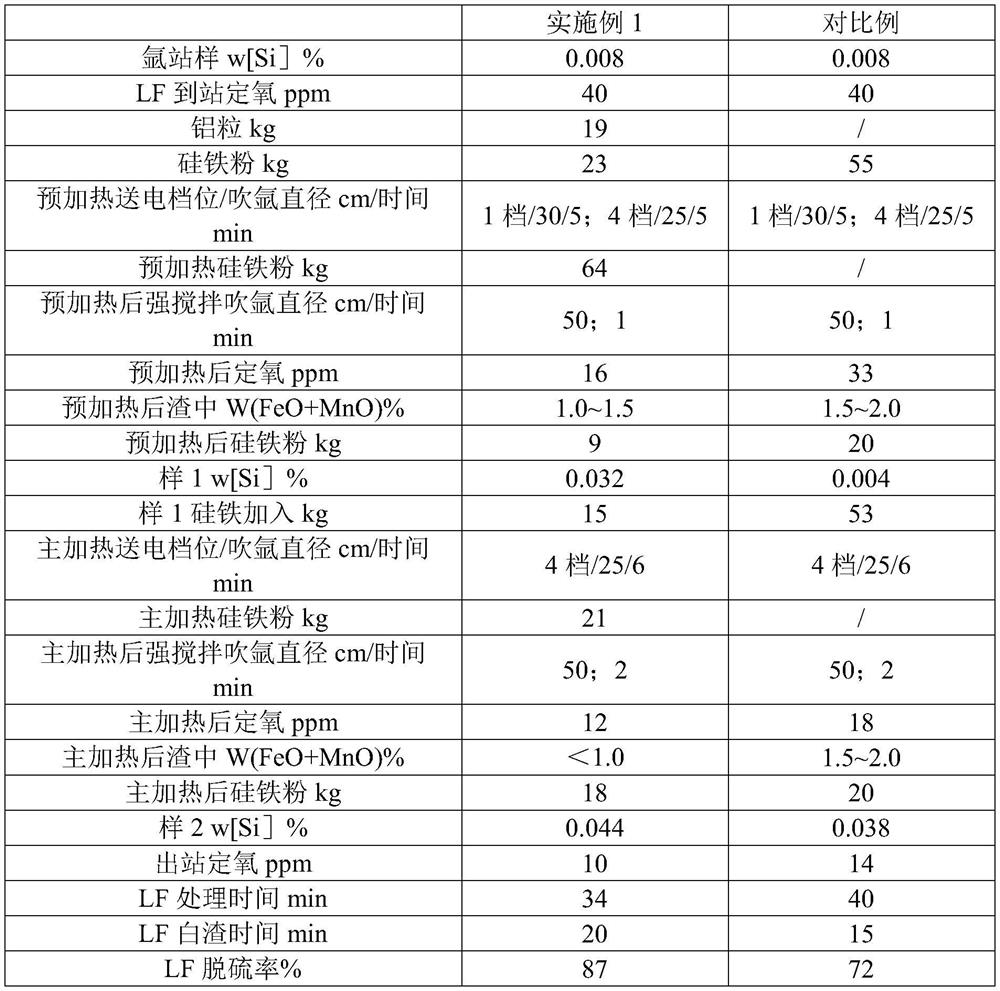

Embodiment 1

[0055] Shaogang's 120tLF converter taps steel with 102kg of silicon manganese, 201kg of ferroaluminum, 50kg of ferrosilicon and 504kg of lime.

[0056] When LF arrives at the station, the oxygen is fixed at 40ppm, and 19kg of aluminum particles are added.

[0057] The exposed diameter of molten steel is 30cm, the first gear is energized for 5 minutes, and then the fourth gear is turned on for 5 minutes. During the process, 503kg of synthetic slag, 144kg of fluorite balls, and 505kg of lime are added. First, according to the argon station sample w(Si)=0.008%, add 23kg of ferrosilicon powder. Then according to the exposed diameter of molten steel 30cm10min, the silicon loss is 0.018%, and the silicon loss is 0.0028% when the first gear is energized for 5 minutes, and the fourth gear is turned on for 5 minutes, and 64kg of ferrosilicon powder is added. When the power is cut off, the molten steel is exposed to a diameter of 50cm and is vigorously stirred for 1min, the silicon los...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com