Knitwear dyeing and drying integrated device

An integrated technology for knitwear, applied in the field of knitwear dyeing and drying integrated devices, can solve the problems of inability to achieve rapid cooling of knitwear, low processing efficiency, effective heat utilization, etc., and achieve full dyeing and rapid cooling operations and energy utilization. The effect of high conversion rate and low processing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

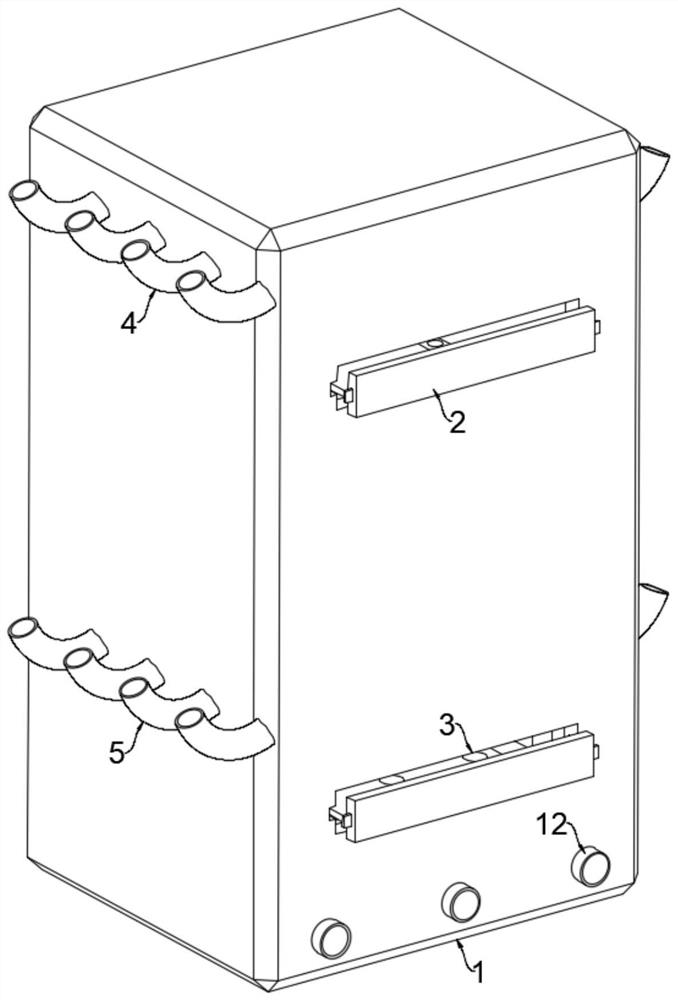

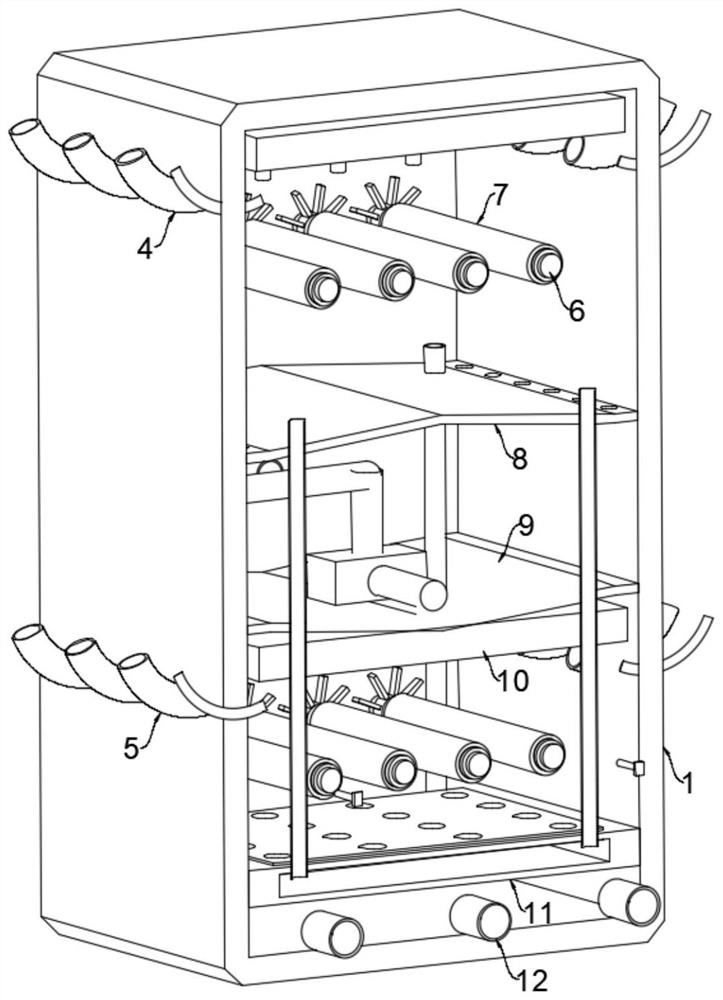

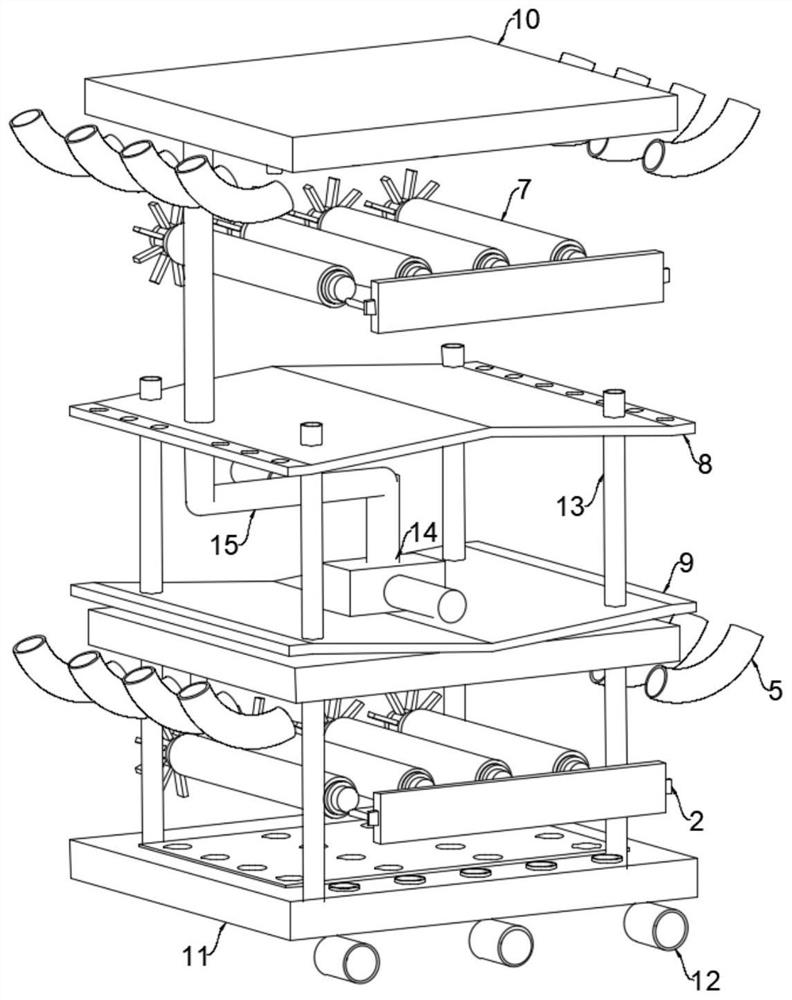

[0034] refer to Figure 1-2 , an integrated device for dyeing and drying knitted fabrics, comprising a box body 1, in which a swash plate 1 8, a swash plate 2 9, a gas collecting box 11 and two liquid storage boxes 10 are fixedly installed;

[0035] It is worth noting that: the upper area of the box body 1 located on the slant plate 1 8 is the placement and processing area of the first batch of knitwear (hereinafter referred to as the processing area 1), and the box body 1 is located on the slant plate 2 9 and the gas collecting box. The area between 11 is the placement and processing area of the second batch of knitted fabrics (hereinafter referred to as the processing area 2), and the area in the box 1 between the sloping plate 1 8 and the sloping plate 2 9 is the storage area for dyeing liquid (hereinafter referred to as the second swash plate). referred to as the storage area).

[0036] refer to Figure 1-3 , two placement mechanisms are installed in the box body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com