Bridge construction supporting method

A support method and bridge construction technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as inability to protect, avoid falling objects from high altitudes, improve overall protection performance, and reduce injuries caused by falling objects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

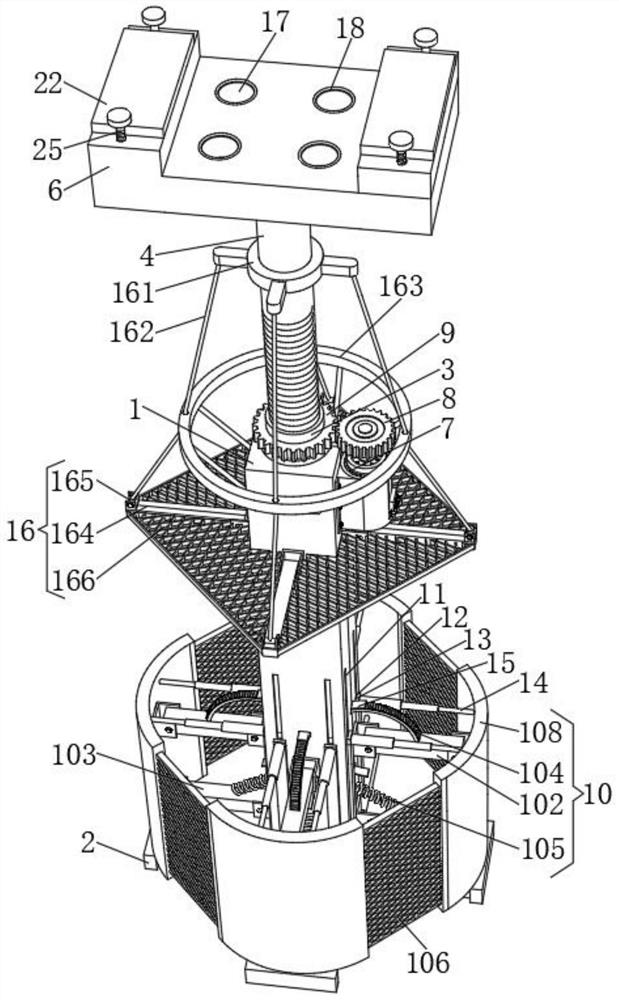

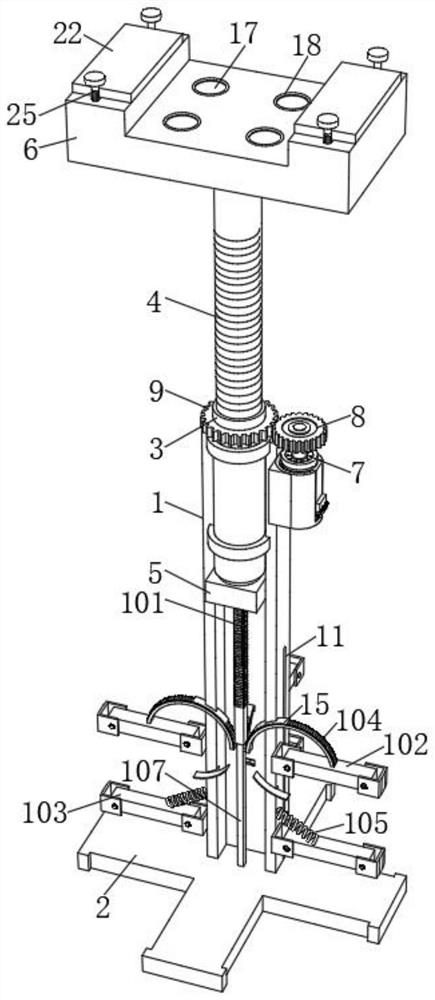

[0034] see Figure 2-8 , the supporting device includes a supporting square column 1 , and a cross base 2 is fixed at the bottom end of the supporting square column 1 . The top of the inner cavity of the supporting square column 1 is rotatably connected with a threaded sleeve 3 through a bearing, and the threaded sleeve 3 is threadedly connected with a lead screw 4 . The bottom end of the screw rod 4 is fixed with a moving block 5 , and the moving block 5 is slidably arranged in the supporting square column 1 . The top of one side of the supporting square column 1 is fixed with a motor 7 through a mounting seat, the output end of the motor 7 is fixed with a first cylindrical gear 8, one side of the first cylindrical gear 8 is meshed with a second cylindrical gear 9, and the second cylindrical gear 9 The inner ring is sleeved on the threaded sleeve 3. The top of the screw rod 4 is fixed with a support base 6, and the motor 7 is used to provide a driving source, so that the sc...

Embodiment 2

[0037] see Figure 2-8 , the supporting device includes a supporting square column 1 , and a cross base 2 is fixed at the bottom end of the supporting square column 1 . The top of the inner cavity of the supporting square column 1 is rotatably connected with a threaded sleeve 3 through a bearing, and the threaded sleeve 3 is threadedly connected with a lead screw 4 . The bottom end of the screw rod 4 is fixed with a moving block 5 , and the moving block 5 is slidably arranged in the supporting square column 1 . The top of one side of the supporting square column 1 is fixed with a motor 7 through a mounting seat, the output end of the motor 7 is fixed with a first cylindrical gear 8, one side of the first cylindrical gear 8 is meshed with a second cylindrical gear 9, and the second cylindrical gear 9 The inner ring is sleeved on the threaded sleeve 3. The top of the screw rod 4 is fixed with a support base 6, and the motor 7 is used to provide a driving source, so that the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com