Hard rock ditching machine and hard rock ditching method

A ditching machine and hard rock technology, applied in the field of hard rock ditching machine and hard rock ditching, can solve problems such as unsuitability of roadheaders, achieve the effects of preventing slipping, ensuring stable operation, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

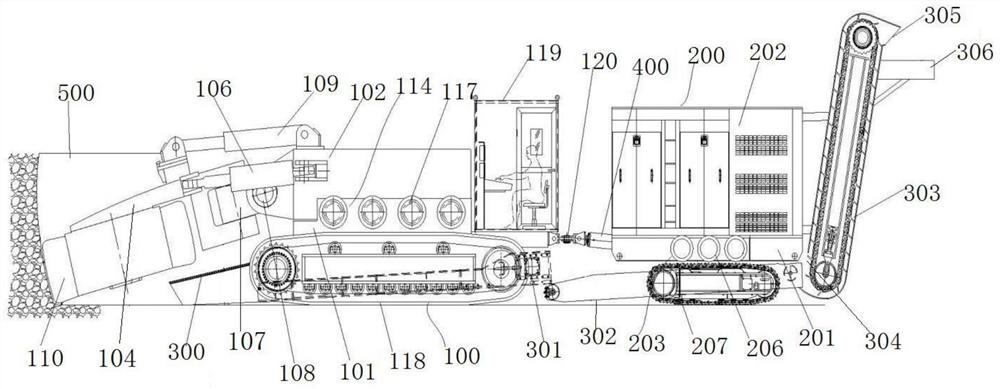

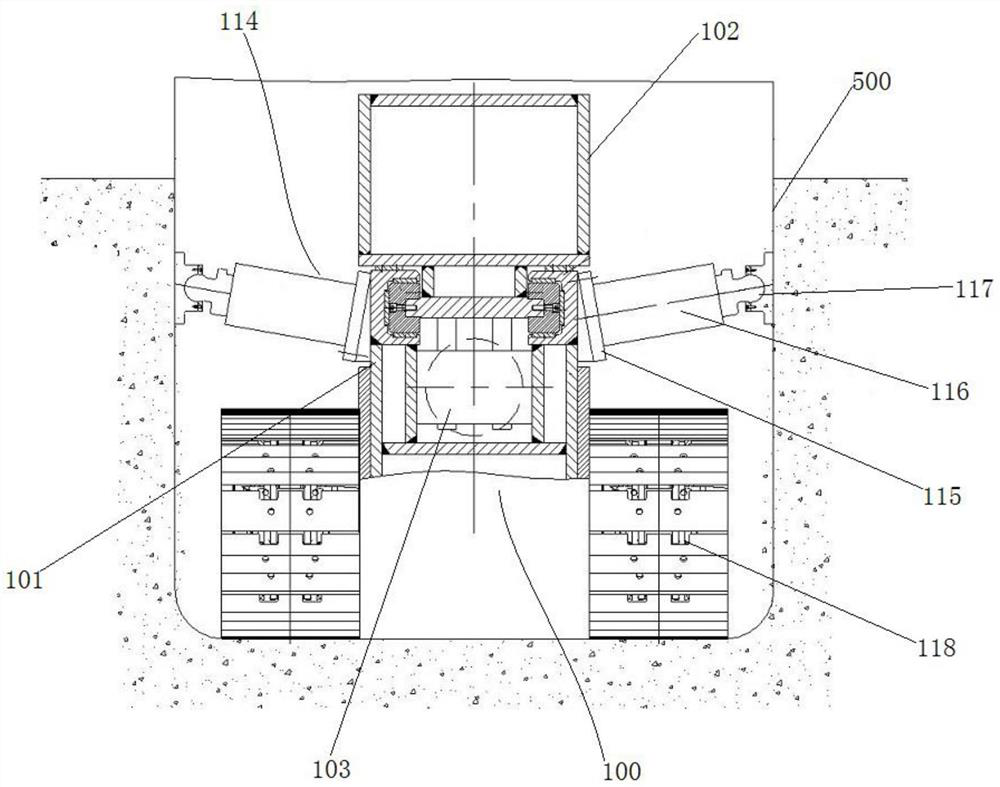

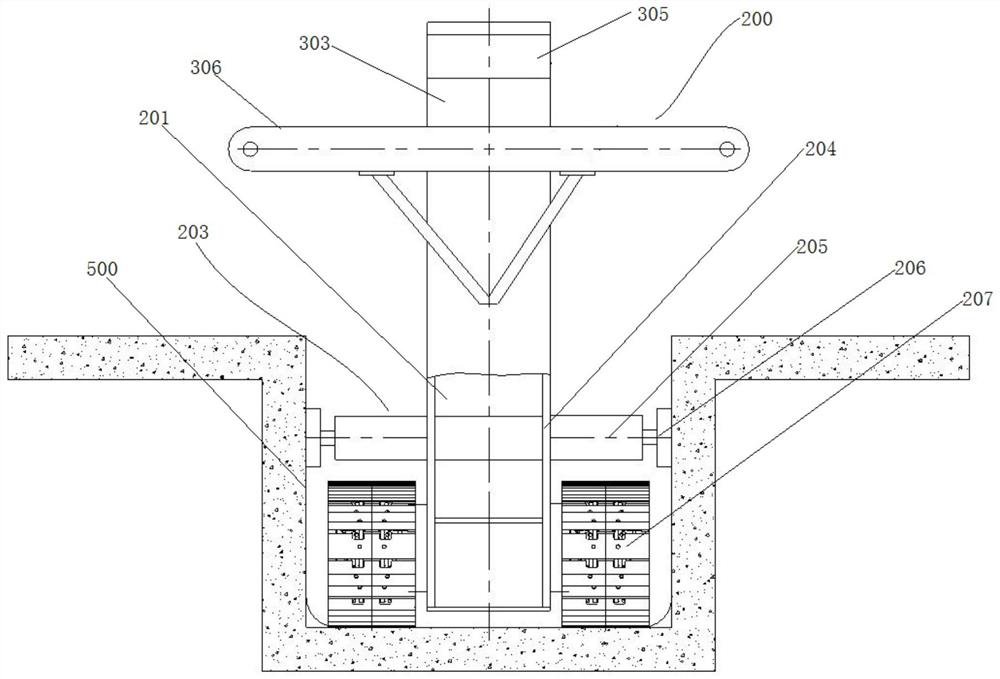

[0043] like figure 1 As shown, the hard rock trencher provided by the present invention includes a front traveling unit 100, a rear traveling unit 200, a telescopic driving device 400 and a muck conveying device, and the front traveling unit 100 is provided with a cutting device for rock breaking and a driving cutting device The swinging cutting cantilever, the rear traveling unit 200 is provided with an energy unit 202 that provides power for the entire trencher. In addition, the front and rear traveling units are also provided with support devices, which are used to support the corresponding side walls of the pipe trench 500 during use. In addition, both ends of the telescopic drive device 400 are respectively connected with the front and rear travel devices, and when the telescopic drive device 400 is stretched, a pushing force or a pulling force is formed between the front and rear travel units. For the convenience of expression, the length direction of the hard rock tren...

Embodiment 2

[0055] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, four sets of front support devices are provided on the left and right sides of the front chassis. In this embodiment, the number of the front support devices on the left and right sides of the front chassis can be set by yourself, for example, three sets of front support devices are provided on the left and right sides of the front chassis.

Embodiment 3

[0057] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, three sets of rear support devices are respectively provided on the left and right sides of the rear chassis. In this embodiment, the number of rear support devices on the left and right sides of the rear chassis can be set by yourself, for example, four sets of rear support devices are provided on each of the left and right sides of the rear chassis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com