One-way dense rib cavity floor system module for concrete structure and construction method of one-way dense rib cavity floor system module

A technology of concrete structure and cavity floor, which is applied in the direction of structural elements, formwork/formwork/work frame, floor slab, etc. It can solve the problem of unreliable connection between prefabricated floor and steel beams, heavy cast-in-place wet work, It does not belong to the problems of prefabricated buildings, and achieves the effect of high rigidity, improving sound insulation and heat insulation performance, and reducing the weight of the floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

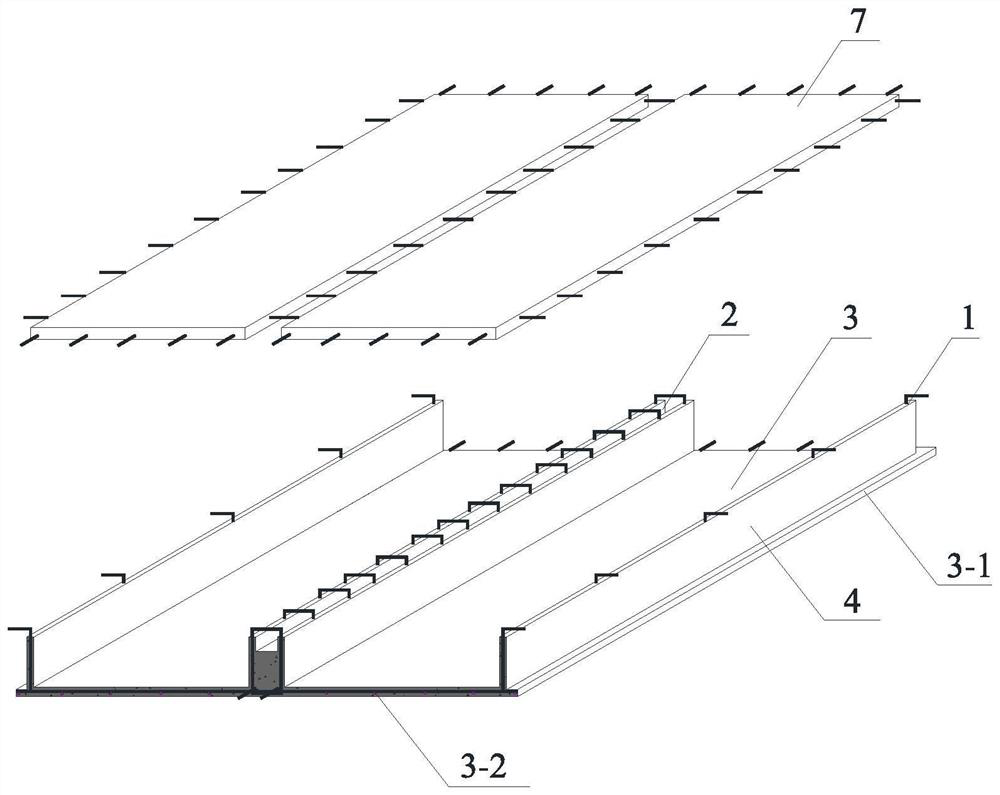

[0040] Figure 1a , 1b It is a schematic structural diagram of a one-way rib cavity floor module for concrete structures in the embodiments of the present invention; in these embodiments, there are two side rib beam half-forms 1 parallel to the inner rib beams 2 respectively.

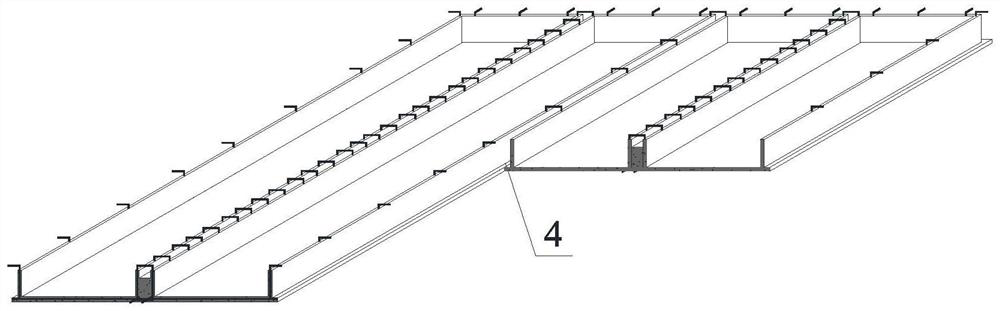

[0041] figure 2 It is a structural schematic diagram of a one-way rib cavity floor module for concrete structures in the embodiment of the present invention; in these embodiments, there are 4 edge rib beam half-moulds 1 and end-to-end connected to form an edge rib beam half-mould frame 1-1 .

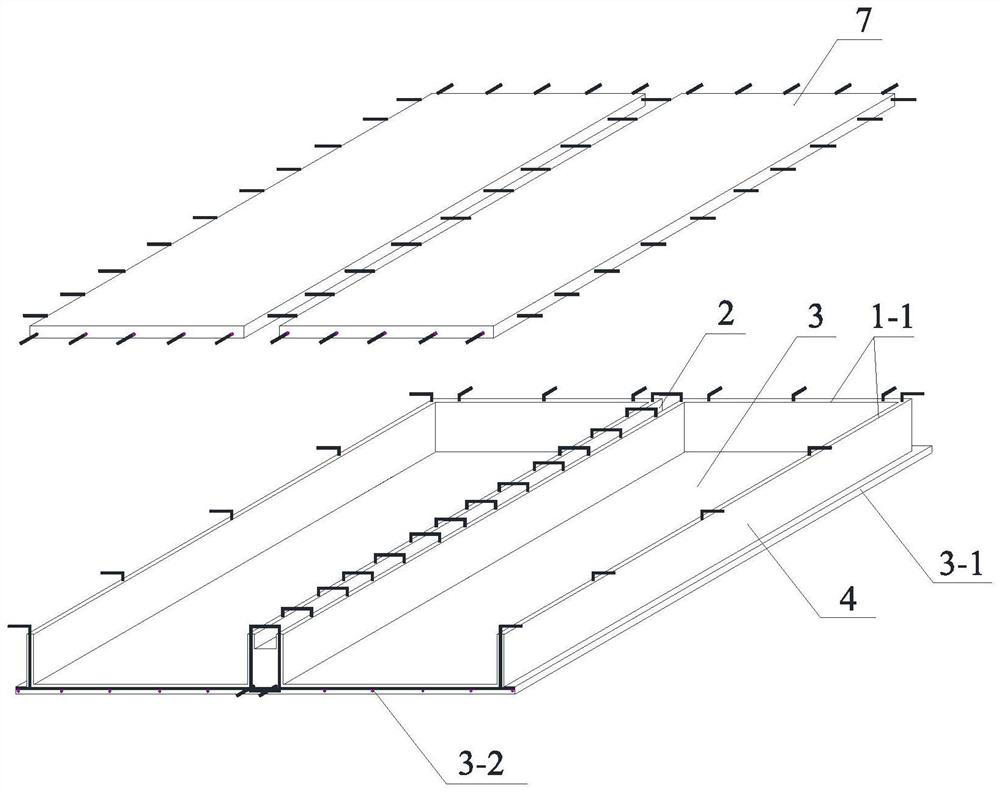

[0042] image 3 It is a structural schematic diagram of a one-way rib cavity floor module for concrete structures in the embodiment of the present invention; in these embodiments, there are 4 edge rib beam half-moulds 1 and end-to-end connected to form an edge rib beam half-mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com