Building elevator shaft inner mold self-lifting construction method and device

A technology for construction devices and elevator shafts, which is applied in the direction of construction, building structure, formwork/formwork/work frame, etc., to achieve the effect of saving labor costs and reducing work processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

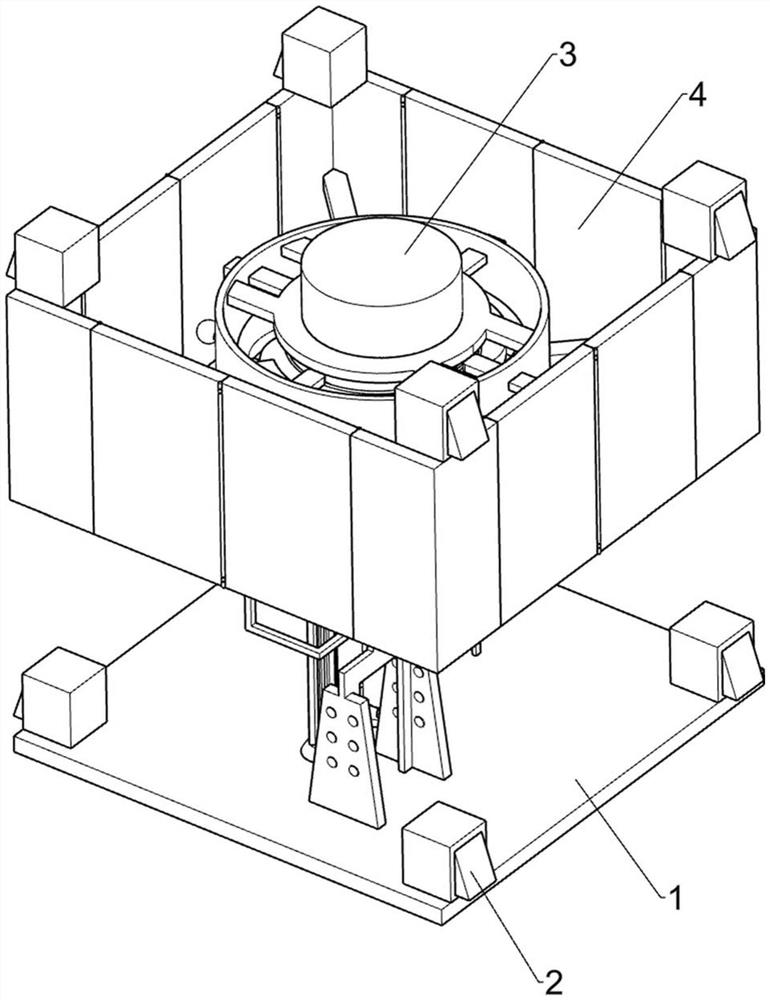

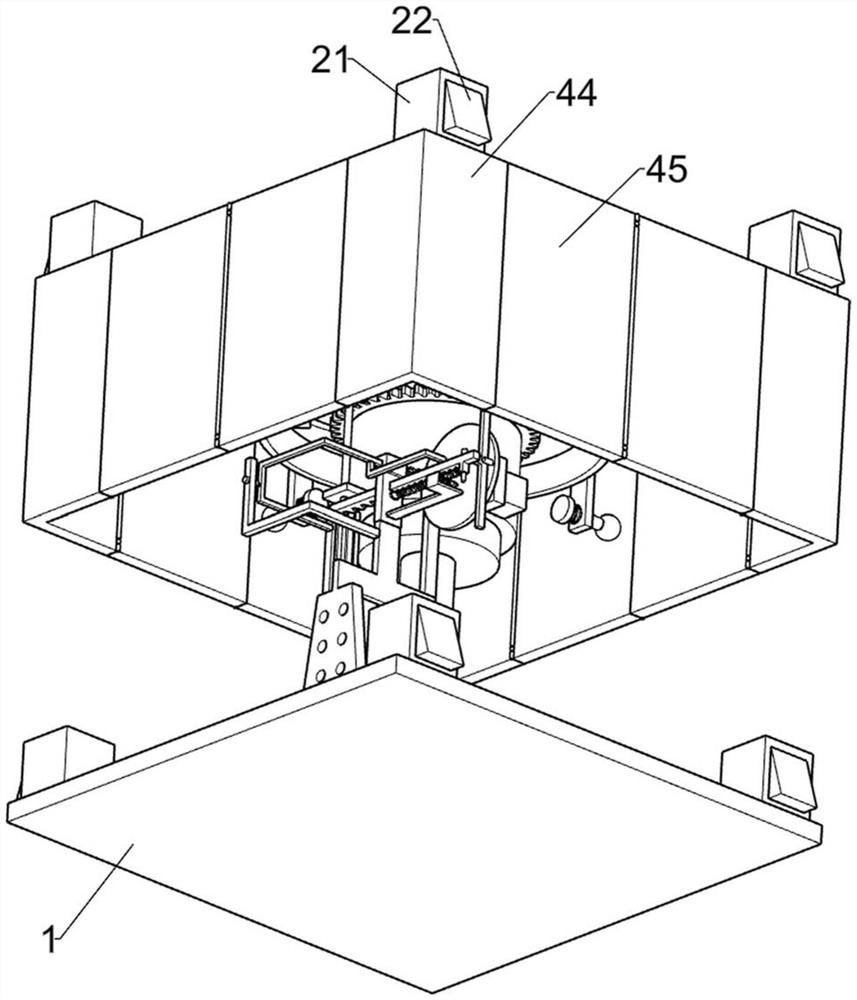

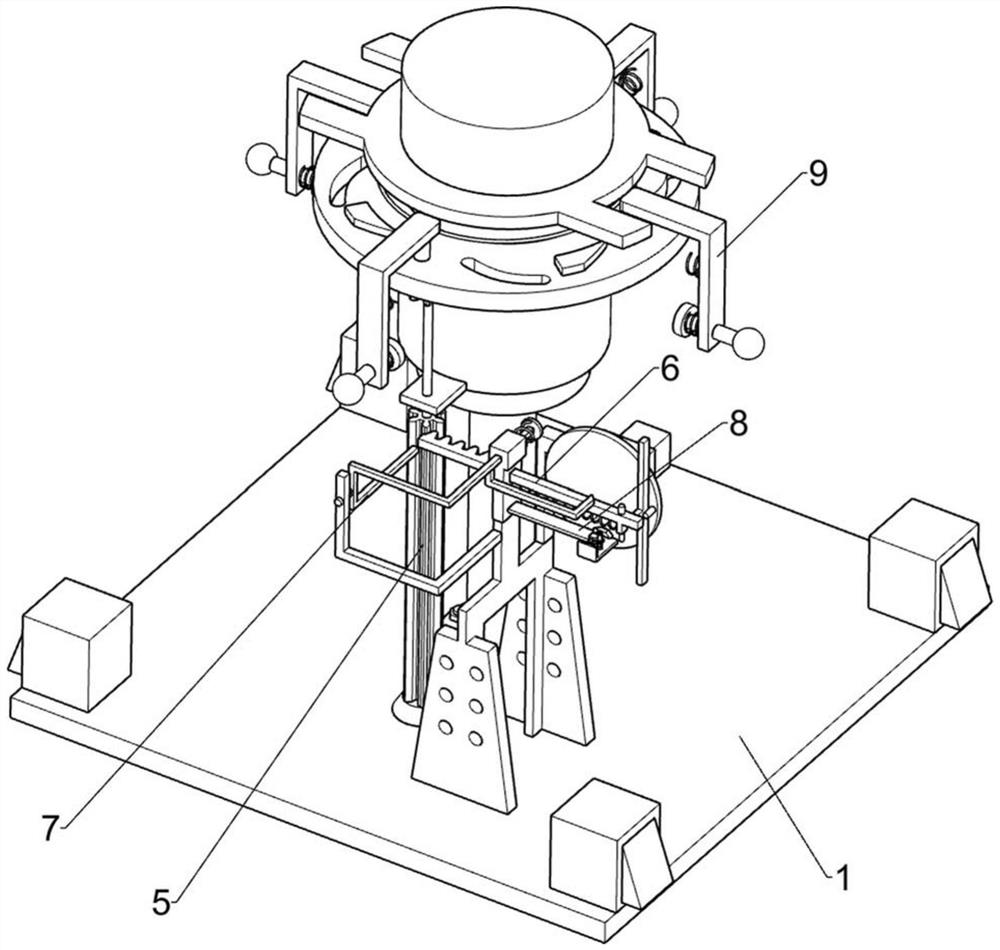

[0030] Self-lifting construction method and construction device of building elevator shaft inner formwork, such as Figure 1-10 As shown, it includes a bottom support plate 1, a support part 2, a climbing part 3, an inner mold shrinking part 4, a driving part 5, a power part 6, a trigger stop part 7 and a lifting part 8, and the bottom support plate 1 is provided with a support Part 2, the top of the bottom support plate 1 is provided with a climbing part 3, the climbing part 3 is provided with an inner mold shrinking part 4, the inner mold shrinking part 4 is also provided with a supporting part 2, a driving part 5 is provided on the climbing part 3, and the bottom part is A power part 6 is provided on the top of the support plate 1 , a trigger stop part 7 is provided on the power part 6 , and a lifting part 8 is provided on the power part 6 .

[0031] The support member 2 includes a hollow sleeve 21, an inclined surface block 22 and a return spring 1 23, four hollow sleeves ...

Embodiment 2

[0044] On the basis of Example 1, as Figure 7 As shown, it also includes an auxiliary blanking part 9, an auxiliary blanking part 9 is provided on the annular guide cylinder 42, and the auxiliary blanking part 9 includes a sloped push bar 91, a driven plate 92, a buffer spring 93, a rubber ball The push rod 94 and the second buffer spring 95, the top of the inclined groove push plate 55 are distributed and welded with four inclined plane push bars 91, the annular guide cylinder 42 is slidably provided with four driven plates 92, and the inclined plane push bars 91 are used to push the The driven plate 92, a buffer spring 93 is connected between the driven plate 92 and the annular guide cylinder 42, the driven plate 92 is slidably connected with a push rod 94 with a rubber ball, and the push rod 94 with a rubber ball is used to impact the folding plate 45. A second buffer spring 95 is connected between the push rod 94 with a rubber ball and the driven plate 92.

[0045] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com