Active lubrication structure of differential mechanism with differential lock

A lubricating structure and differential technology, which is applied in the direction of differential transmission, gear lubrication/cooling, transmission, etc., can solve the problems of wear, sintering, and insufficient lubrication of the internal components of the differential, so as to prevent sintering and improve Service life, stable lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the objectives, technical solutions and advantages of the present invention clearer, the features and performance of an active lubricating structure for a differential with a differential lock in the present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

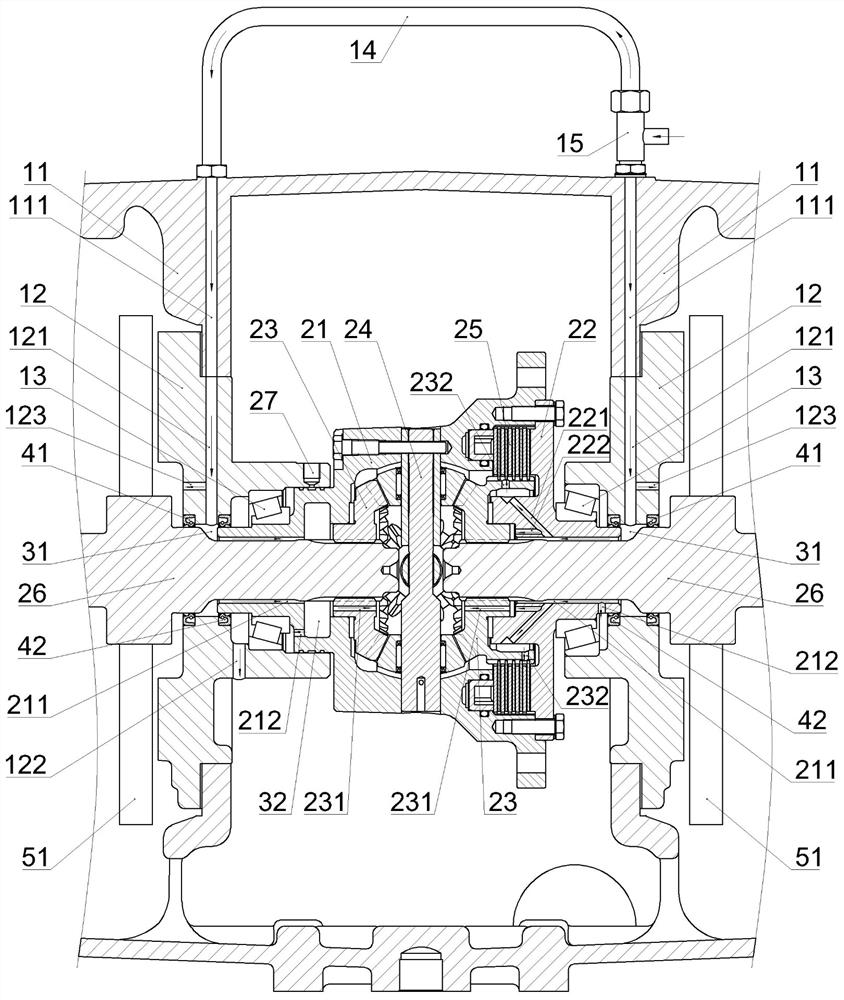

[0032] see figure 1 , an active lubricating structure for a differential with a differential lock, comprising a gearbox housing 11 and a differential rotatably arranged inside the gearbox housing 11 .

[0033] The left and right sides of the gearbox housing 11 are respectively provided with a differential bearing support 12 , and the two differential bearing supports 12 are both provided with a first shaft hole and the two first shaft holes are coaxially arranged.

[0034] The differential is arranged inside the gearbox housing 11 , and the differential includes a differential housing, side gears 23 , planetary gear assemblies 24 , diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com