Code sensor, code and information setting method and code and information reading method

A sensor and sensor body technology, applied in the field of coded sensors, can solve the problems of sensor surface modification, coating information and calibration information cannot be recorded, the number of information is limited, and the individual sensor parameter information cannot be recorded, so as to avoid the limitation of networking and communication Effects of delay, good user experience, and avoidance of malicious attacks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

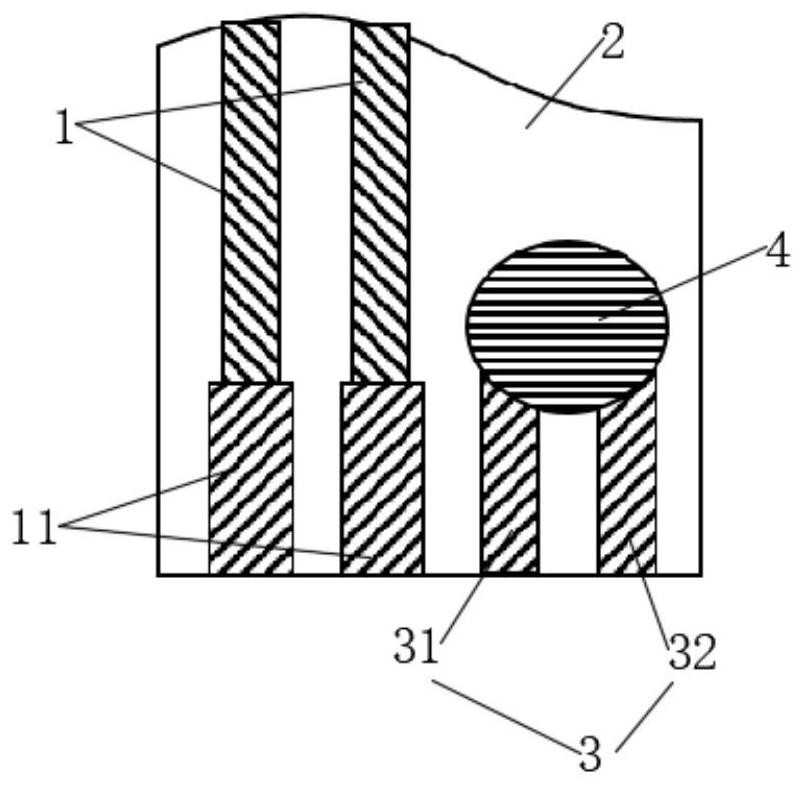

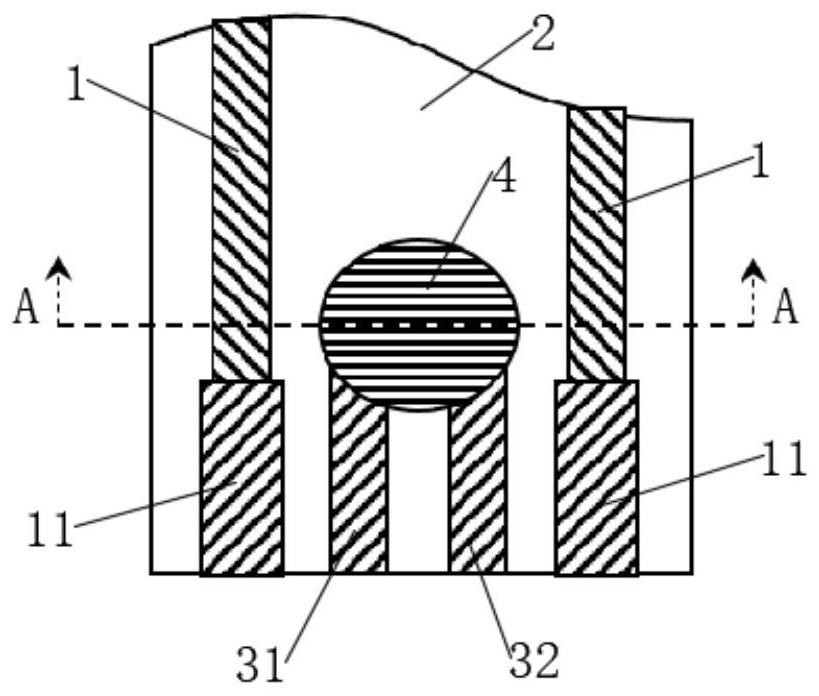

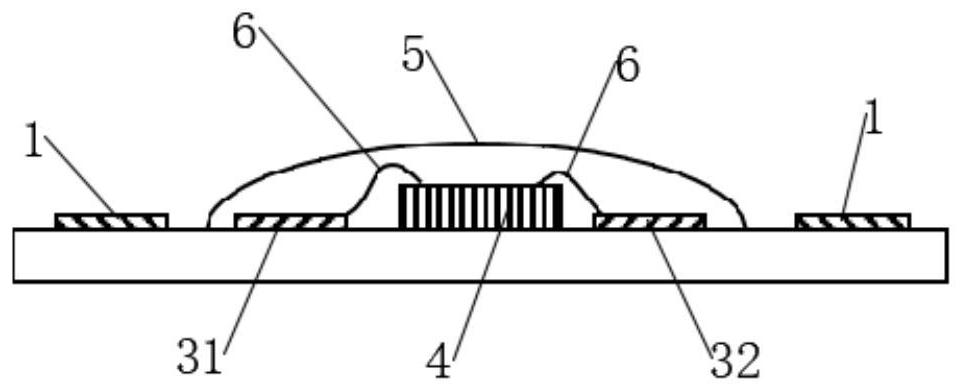

[0090] The present invention proposes a coded sensor for mass-produced biosensors or electrochemical sensors. The sensor code is stored by arranging an integrated circuit 4 on the sensor, thereby realizing the uniqueness of the sensor code. Affected by the area or volume of the sensor, it does not affect the structural design of the sensor, the amount of information that can be recorded is large, information can be added later, and no user intervention is required during use, the host computer automatically recognizes the sensor code, and automatically reads the relevant parameters. Drive and measure. At the same time, it is free from the restrictions of Internet connection and remote database, and it also avoids the possibility of being attacked in the process of interacting with remote data.

[0091] Since the integrated circuit 4 has a large storage space, it can record more data, uniquely encode the sensor, and store sensor-related information and measurement parameters, i...

Embodiment 2

[0103] like Figure 7 As shown in the figure, a method for setting the code and information of a coding sensor includes the following steps:

[0104] S110, production sensor;

[0105] S120, performing quality control form detection on the sensor;

[0106] S130, judging whether the sensor has passed the quality control test, if it passes, enter S140, otherwise, it is judged that the sensor is a defective product;

[0107] S140, test the quality control performance of the sensor;

[0108] S150, determine whether the sensor has passed the quality control inspection, if it passes, enter S160; otherwise, determine that the sensor is a defective product;

[0109] S160, assign a unique code to the sensor;

[0110] S170, determine sensor production information, calibration information, and measurement parameter information;

[0111] S180, paste, bond and install the integrated circuit on the sensor;

[0112] S190, encapsulating the integrated circuit as a whole to form an encaps...

Embodiment 3

[0119] like Figure 8 As shown in the figure, a method for setting the code and information of a coding sensor includes the following steps:

[0120] S410, production sensor;

[0121] S420, performing quality control form detection on the sensor;

[0122] S430, judging whether the sensor has passed the quality control test, if it passes, then go to S440, otherwise, it is judged that the sensor is a defective product;

[0123] S440, test the quality control performance of the sensor;

[0124] S450, determine whether the sensor has passed the quality control inspection, if it passes, enter S460; otherwise, determine that the sensor is a defective product;

[0125] S460, assign a unique code to the sensor;

[0126] S470, determine sensor production information, calibration information, and measurement parameter information;

[0127] S480, programming the sensor code, production information, calibration information, and measurement parameters into the integrated circuit throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com