Automatic wire arranging device

A technology of automatic wire arrangement and take-up device, applied in the field of wire rope winding equipment, can solve the problems of uneven collection, disorderly arrangement of take-up wires, etc., and achieve the effects of fast wire-receiving process, improving production efficiency and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

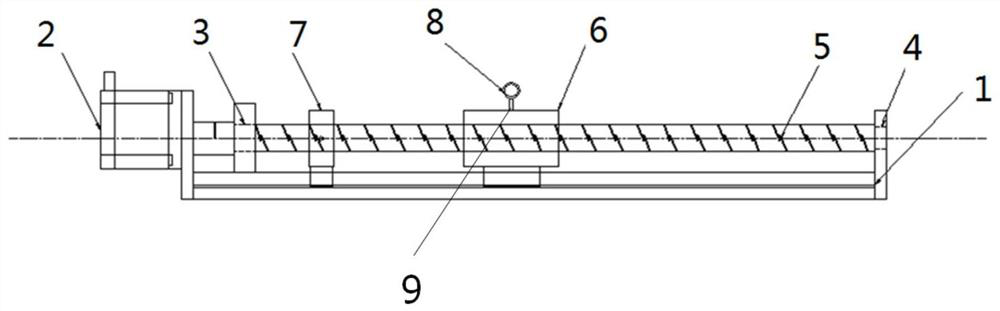

[0022] see Figure 1 to Figure 3 , an automatic arranging device, including a bracket 1 and a lateral movement device; a rotating motor 2 is provided on one side of the bracket 1, the rotating motor 2 and the bracket 1 are fixed and installed by bolts, and the output end of the rotating motor 2 is connected to the shaft through a coupling. The lateral moving device is connected; a mounting seat is provided on the bracket 1, and the mounting seat includes a first mounting seat 3 and a second mounting seat 4; a first mounting seat 3 is provided on the side close to the rotating motor 2, A first installation hole is arranged in the middle, a second installation seat 4 is arranged at one end away from the rotating motor 2, and a second installation hole is arranged in the middle of the second installation seat 4, and the lateral movement device is rotatably installed in the first installation hole and the second installation hole. in the mounting hole;

[0023] The lateral moveme...

Embodiment 2

[0033] This embodiment is basically the same as the first embodiment, the difference is: figure 1 As shown, a cable arrangement module is used, including a rotating motor 2, a bracket 1, a lead screw 5, a sliding block 6, and a bearing; a limit stop 7 is added on the lead screw 5 to control the sliding distance of the sliding block 6. When After the sliding block 6 hits the limit stop 7, the rotating motor 2 is reversed, so that the sliding block 6 slides in the other direction; a wire loop 8 is added on the sliding block 6 to support and guide the wire rope and cooperate with the horizontal The mobile device completes the wiring.

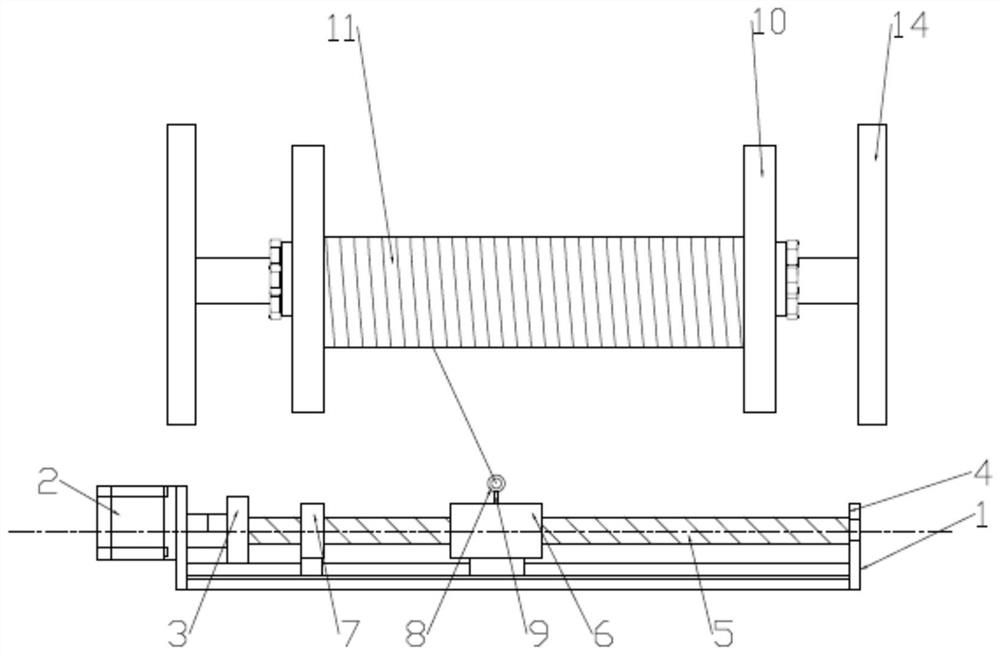

[0034] 1. The start-stop switch of the automatic cable arrangement device is connected in parallel with the start-stop of the take-up reel 11, so that the take-up reel 11 and the automatic cable arrangement device can be started and stopped at the same time;

[0035] 2. Collect the position of the sliding block 6 through the limit stop 7, and cont...

Embodiment 3

[0042] This embodiment is basically the same as the first embodiment, the difference is: figure 1 As shown, when arranging the wire, the traditional take-up reel 11 is prone to inversion after taking up the wire, thus seriously affecting the tightness of the take-up reel 11 when taking up the wire. Therefore, if the wire take-up reel 11 is reversed, the tightness of the cable will also be affected. Therefore, the present application also has a device for preventing the wire take-up reel 11 from being reversed.

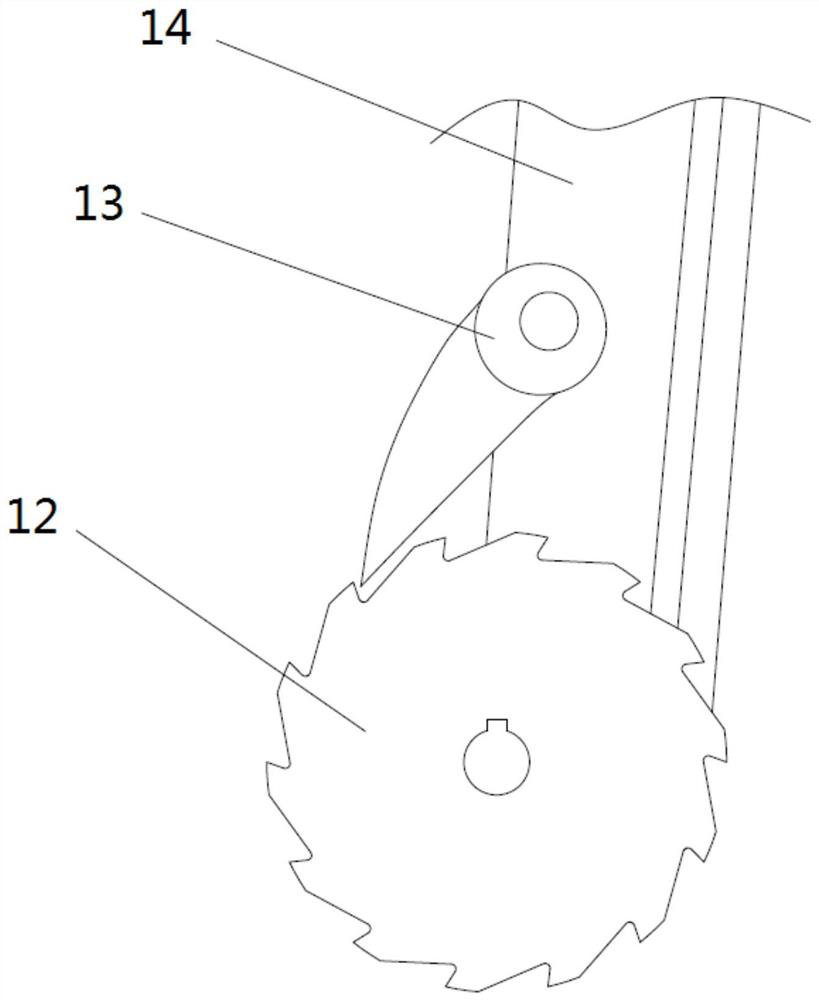

[0043] The take-up reel 11 is circular, and the take-up reel 11 is installed on the frame. The take-up reel 11 includes an inner take-up reel and an outer take-up reel, wherein the inner take-up reel rotates around the rotating shaft, and the outer take-up reel is arranged on the inner take-up reel. On the outside of the spool, a limit ratchet 12 is arranged on both sides of the outer take-up reel, and the limit ratchet 12 surrounds the outer take-up reel for a full ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com