Air cylinder and hot runner system with same

A technology of a cylinder and a cylinder block is applied in the field of a cylinder and a hot runner system having the cylinder, which can solve the problems of affecting the sealing effect of the valve needle, increasing the production and processing costs of injection products, and reducing the service life of the cylinder, and achieving simple adjustment steps. Convenience, improve the injection quality, avoid the effect of rigid collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below with reference to the embodiments and the accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

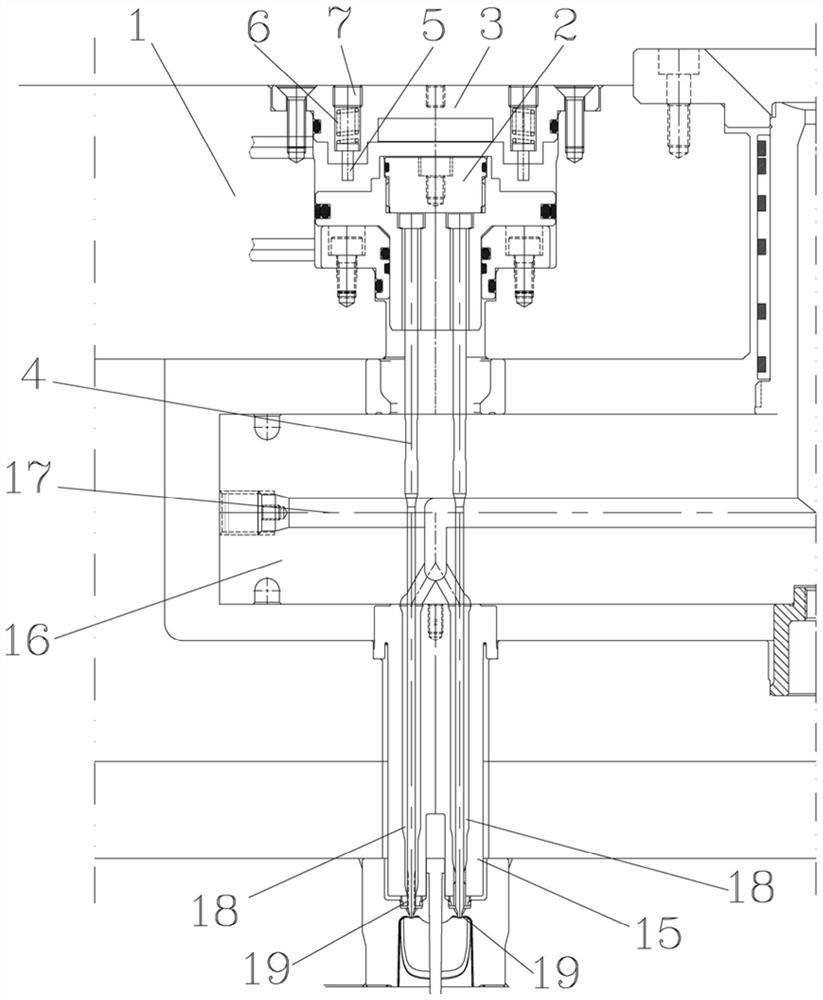

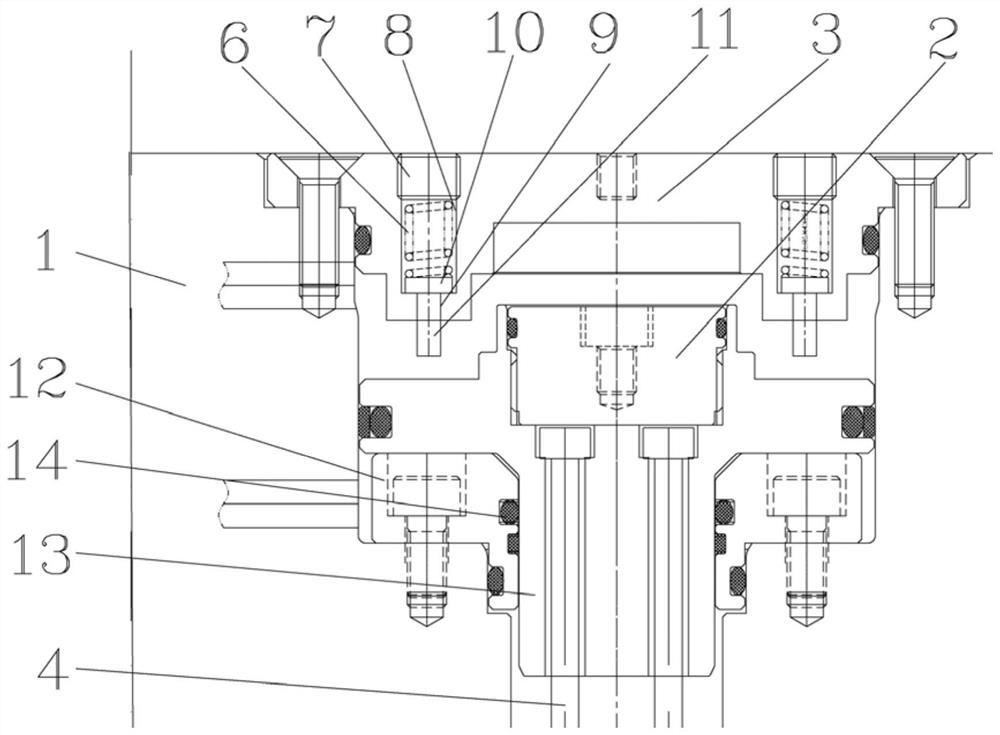

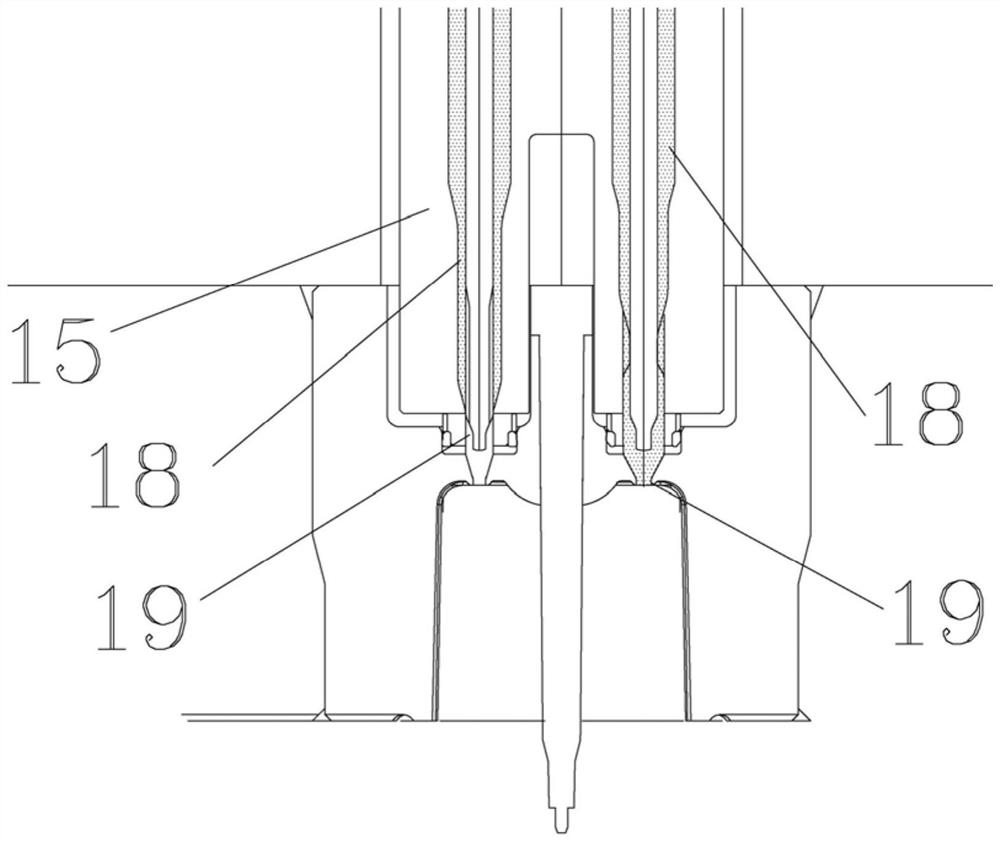

[0021] like Figure 1 to Figure 3 As shown, a cylinder provided by the present invention includes a cylinder body 1, a piston 2 movably arranged in the cylinder body 1, a cylinder head 3 arranged above the cylinder body 1 and used to seal the piston 2 in the cylinder body 1, The valve needle 4 arranged in the cylinder body 1 and connected with the piston 2, and the resisting member 5, the elastic member 6 and the adjusting member 7 respectively movably arranged in the cylinder head 3, the resisting member 5 can protrude to the cylinder body 1 and In conflict with the piston 2 ; the elastic member 6 is connected to the adjusting member 7 and the conflicting member 5 ; the adjusting member 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com