Sleeving and pasting jig for precise plastic part

A precision plastic and jig technology, applied in the field of consumer electronics processing, can solve problems such as inability to guarantee product cleanliness, product appearance damage, and difficulty in meeting mass production, and achieve improved fitting accuracy, production efficiency and good quality. efficiency and improve operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

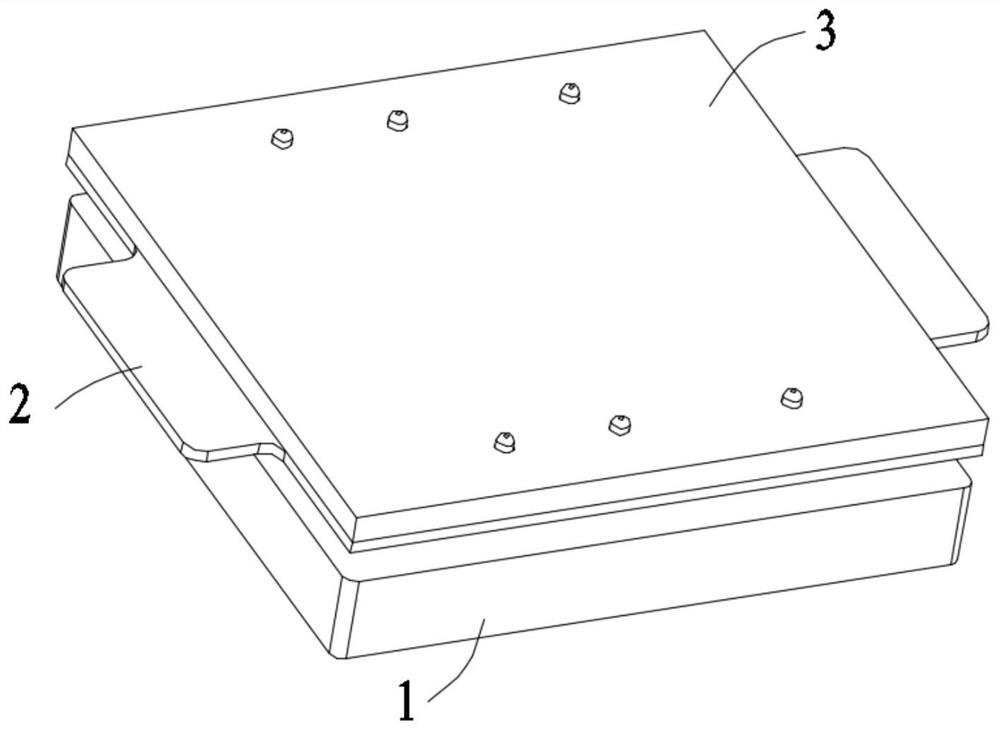

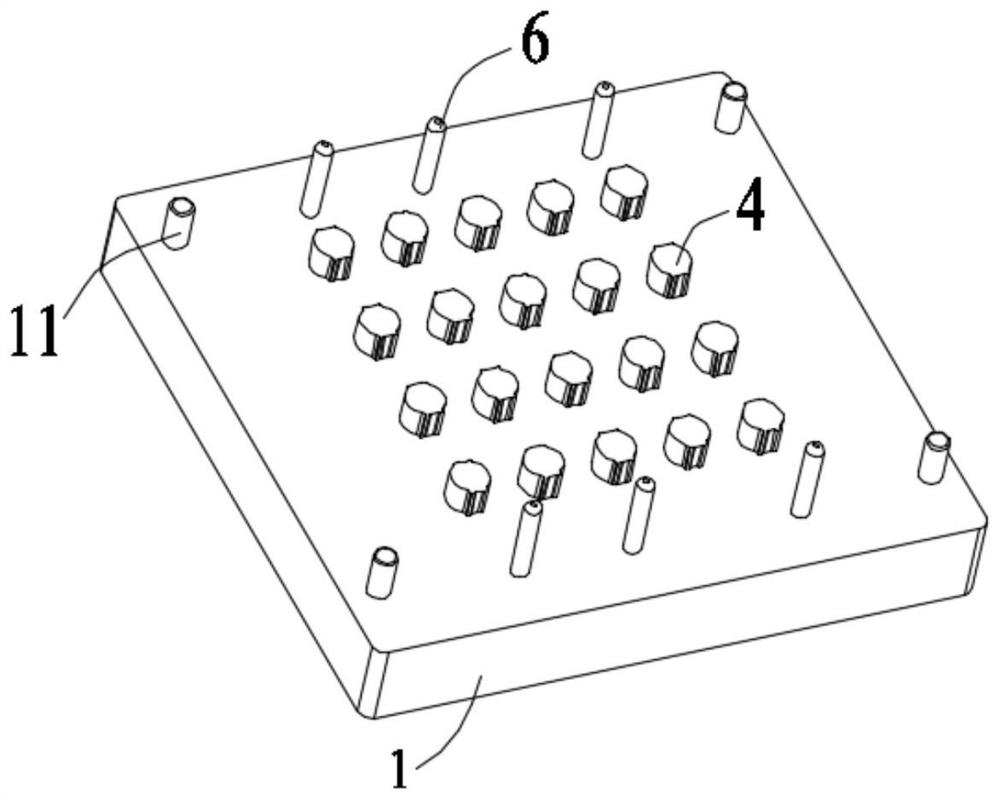

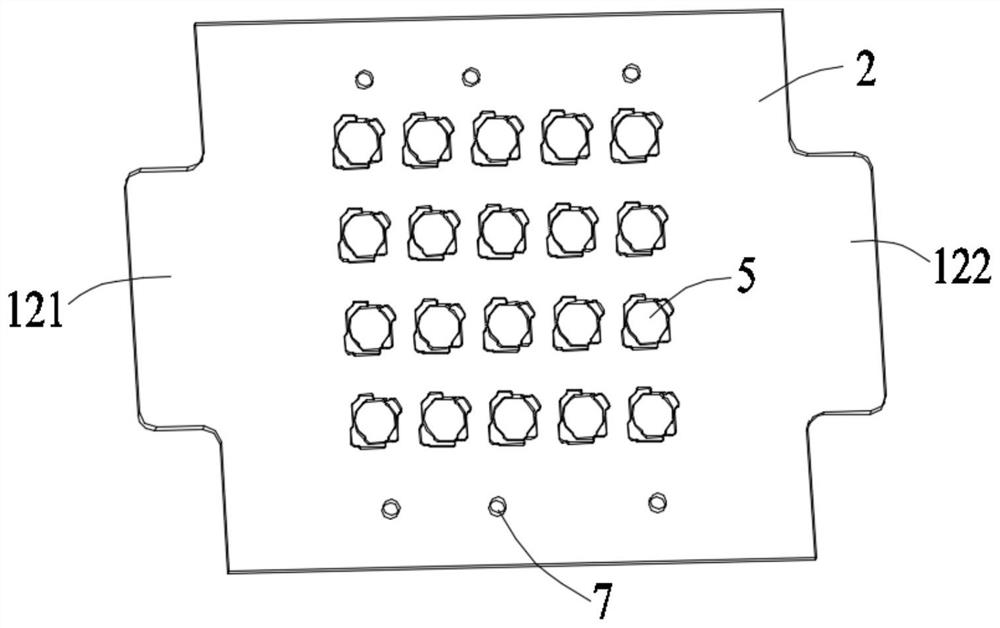

[0021] Embodiment 1: A sleeve jig for precision plastic parts, comprising: a base plate 1, a copy plate 2 and a cover plate 3, the copy plate 2 is located between the base plate 1 and the cover plate 3, the base plate 1 is provided with a number of bosses 4 at intervals, the profiling plate 2 is provided with a number of profiling grooves 5 corresponding to the bosses 4 for placing plastic parts, and the base plate 1 is located on a number of bosses 5. There are several positioning pins 6 on both sides of the table 4, and through holes 7 corresponding to the positioning pins 6 are opened on both sides of the several copying grooves 5 on the profile plate 2, and the surface of the boss 4 has a weak surface. The sticky double-sided adhesive layer 8, the surface of the weakly sticky double-sided adhesive layer 8 opposite to the boss 4 is attached with a foam layer 9, and the surface of this foam layer 9 is covered with a strong-stick double-sided adhesive layer 10;

[0022] The f...

Embodiment 2

[0027] Embodiment 2: A sleeve jig for precision plastic parts, comprising: a base plate 1, a copy plate 2 and a cover plate 3, the copy plate 2 is located between the base plate 1 and the cover plate 3, the base plate 1 is provided with a number of bosses 4 at intervals, the profiling plate 2 is provided with a number of profiling grooves 5 corresponding to the bosses 4 for placing plastic parts, and the base plate 1 is located on a number of bosses 5. There are several positioning pins 6 on both sides of the table 4, and through holes 7 corresponding to the positioning pins 6 are opened on both sides of the several copying grooves 5 on the profile plate 2, and the surface of the boss 4 has a weak surface. The sticky double-sided adhesive layer 8, the surface of the weakly sticky double-sided adhesive layer 8 opposite to the boss 4 is attached with a foam layer 9, and the surface of this foam layer 9 is covered with a strong-stick double-sided adhesive layer 10;

[0028] The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com