Vibration frequency test and durability assessment method for exhaust system

An exhaust system and vibration frequency technology, which is applied in the field of exhaust system vibration frequency testing and durability assessment, can solve the problems that the test results do not have too high reference value, the exhaust system testing and assessment costs are high, and achieve reliable test results, Ease of implementation and low cost of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

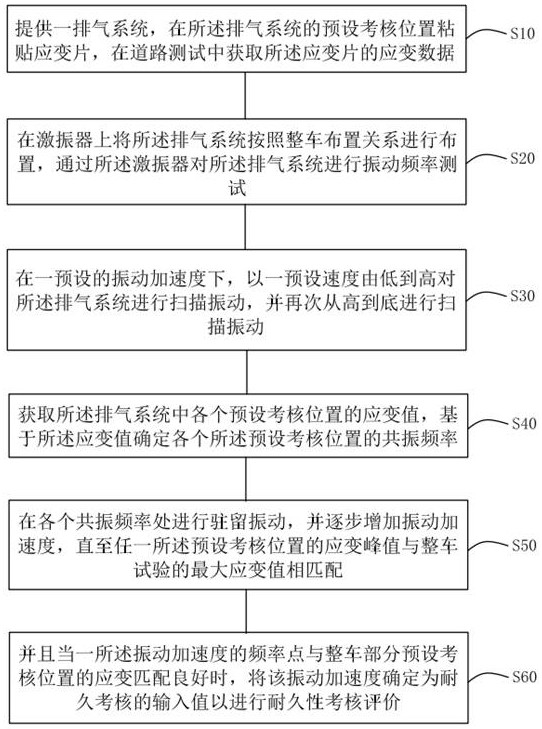

[0042] see Figure 1-3 , the first embodiment of the present invention provides an exhaust system vibration frequency test and durability assessment method, please refer to figure 1 , the method includes steps S10-S60:

[0043] Step S10 , providing an exhaust system, pasting strain gauges at a preset assessment position of the exhaust system, and obtaining strain data of the strain gauges in a road test;

[0044] Step S20, arranging the exhaust system on the vibration exciter according to the layout relationship of the whole vehicle, and performing a vibration frequency test on the exhaust system through the vibration exciter;

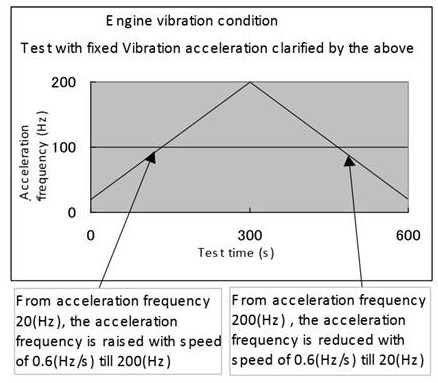

[0045] Step S30, under a preset vibration acceleration, scan and vibrate the exhaust system from low to high at a preset speed, and scan and vibrate from high to bottom again;

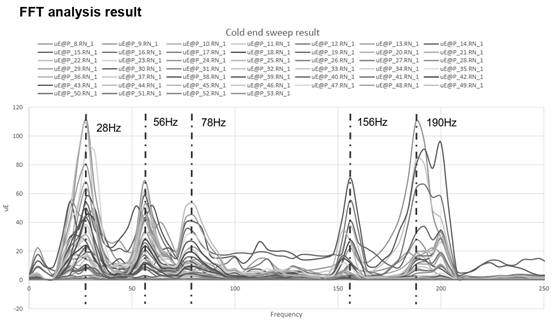

[0046] Step S40, acquiring strain values of each preset assessment position in the exhaust system, and determining the resonance frequency of each of the preset assessment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com