Health state evaluation method, system and equipment of numerical control machine tool and medium

A technology of health status and CNC machine tools, applied in manufacturing computing systems, data processing applications, instruments, etc., can solve the problems of CNC system failures, inaccurate assessment of the health status of mechanical components, and different operating conditions, so as to avoid serious failures, Realize the effect of predictive maintenance, accurate and real-time health evaluation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

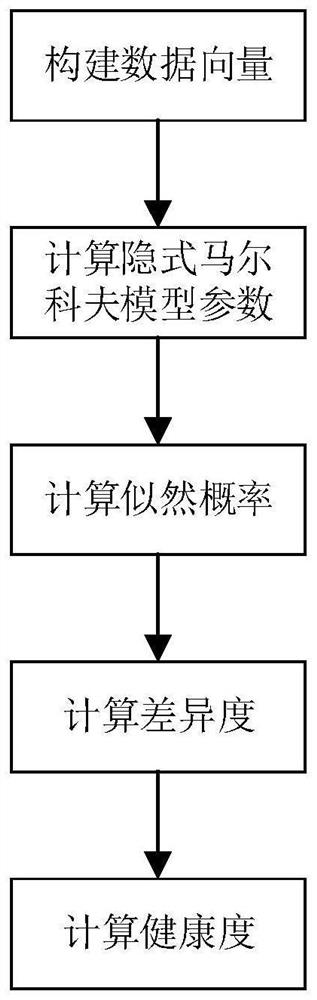

[0045] like figure 1 As shown, this embodiment provides a method for evaluating the health state of a numerically controlled machine tool, which includes the following steps:

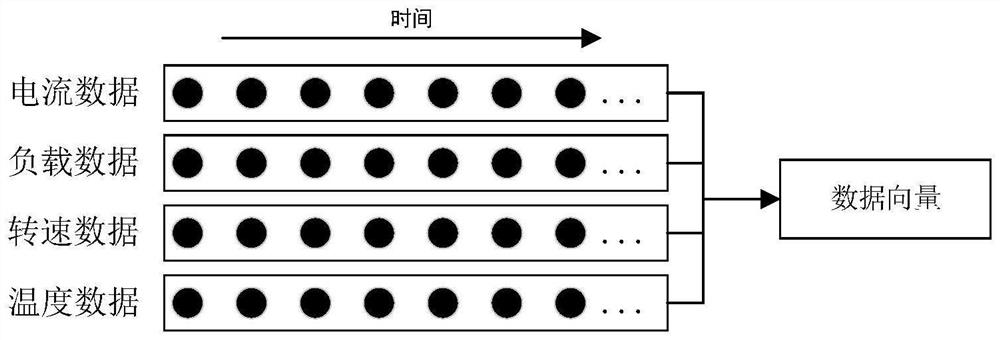

[0046] 1) Obtaining training sample data sets corresponding to several preset working conditions based on the collected historical operation data of the CNC machine tool;

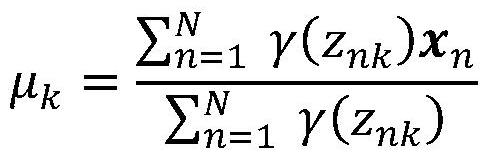

[0047]2) Based on each training sample data set, the model parameters of the health state analysis model are trained and the corresponding likelihood probability is calculated, and each group of model parameters after training is formed into a preset model parameter collection θ that represents different preset working conditions of the machine tool all , compose each likelihood probability into a preset likelihood probability set P 0 ;

[0048] 3) Based on the obtained preset model parameter set θ all and the preset likelihood probability set P 0 , to evaluate the health status of the current CNC machine tools.

[0049] Prefera...

Embodiment 2

[0085] The above embodiment 1 provides a health state evaluation method of a numerically controlled machine tool, and correspondingly, this embodiment provides a health state evaluation system of a numerically controlled machine tool. The system provided in this embodiment can implement the method for evaluating the health state of a numerically controlled machine tool in Embodiment 1, and the system can be implemented by software, hardware, or a combination of software and hardware. For example, the system may include integrated or separate functional modules or functional units to perform corresponding steps in each method of Embodiment 1. Since the system of this embodiment is basically similar to the method embodiment, the description process of this embodiment is relatively simple, and the relevant part may refer to the partial description of Embodiment 1, and the embodiment of the system provided by this embodiment is only illustrative .

[0086] The health state evalua...

Embodiment 3

[0091] This embodiment provides a processing device corresponding to the health state evaluation method of a numerically controlled machine tool provided in this embodiment 1, and the processing device may be a processing device used for a client, such as a mobile phone, a notebook computer, a tablet computer, a desktop computer, etc. , to perform the method of Example 1.

[0092] The processing device includes a processor, a memory, a communication interface and a bus, and the processor, the memory and the communication interface are connected through the bus to complete mutual communication. A computer program that can be run on the processor is stored in the memory, and when the processor runs the computer program, the method for evaluating the health state of a numerically controlled machine tool provided in Embodiment 1 is executed.

[0093] In some embodiments, the memory may be a high-speed random access memory (RAM: Random Access Memory), and may also include a non-vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com